Page 39 - New Cloth Market December 2022 Digital Edition

P. 39

Industrial Hemp Fibers: An Overview

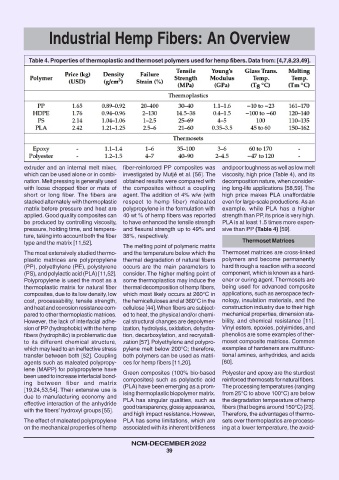

Table 4. Properties of thermoplastic and thermoset polymers used for hemp fibers. Data from: [4,7,8,23,49].

extruder and an internal melt mixer, fiber-reinforced PP composites was and poor toughness as well as low melt

which can be used alone or in combi- investigated by Mutjé et al. [56]. The viscosity, high price (Table 4), and its

nation. Melt pressing is generally used obtained results were compared with decomposition nature, when consider-

with loose chopped fiber or mats of the composites without a coupling ing long-life applications [58,59]. The

short or long fiber. The fibers are agent. The addition of 4% w/w (with high price makes PLA unaffordable

stacked alternately with thermoplastic respect to hemp fiber) maleated even for large-scale productions. As an

matrix before pressure and heat are polypropylene in the formulation with example, while PLA has a higher

applied. Good quality composites can 40 wt % of hemp fibers was reported strength than PP, its price is very high.

be produced by controlling viscosity, to have enhanced the tensile strength PLA is at least 1.5 times more expen-

pressure, holding time, and tempera- and flexural strength up to 49% and sive than PP (Table 4) [59].

ture, taking into account both the fiber 38%, respectively.

type and the matrix [11,52]. Thermoset Matrices

The melting point of polymeric matrix

The most extensively studied thermo- and the temperature below which the Thermoset matrices are cross-linked

plastic matrices are polypropylene thermal degradation of natural fibers polymers and become permanently

(PP), polyethylene (PE), polystyrene occurs are the main parameters to hard through a reaction with a second

(PS), and polylactic acid (PLA) [11,52]. consider. The higher melting point of component, which is known as a hard-

Polypropylene is used the most as a some thermoplastics may induce the ener or curing agent. Thermosets are

thermoplastic matrix for natural fiber thermal decomposition of hemp fibers, being used for advanced composite

composites, due to its low density, low which most likely occurs at 260°C in applications, such as aerospace tech-

cost, processability, tensile strength, the hemicelluloses and at 360°C in the nology, insulation materials, and the

and heat and corrosion resistance com- cellulose [44]. When fibers are subject- construction industry due to their high

pared to other thermoplastic matrices. ed to heat, the physical and/or chemi- mechanical properties, dimension sta-

However, the lack of interfacial adhe- cal structural changes are depolymer- bility, and chemical resistance [11].

sion of PP (hydrophobic) with the hemp ization, hydrolysis, oxidation, dehydra- Vinyl esters, epoxies, polyimides, and

fibers (hydrophilic) is problematic due tion, decarboxylation, and recrystalli- phenolics are some examples of ther-

to its different chemical structure, zation [57]. Polyethylene and polypro- moset composite matrices. Common

which may lead to an ineffective stress pylene melt below 200°C; therefore, examples of hardeners are multifunc-

transfer between both [52]. Coupling both polymers can be used as matri- tional amines, anhydrides, and acids

agents such as maleated polypropy- ces for hemp fibers [11,20]. [60].

lene (MAPP) for polypropylene have

Green composites (100% bio-based Polyester and epoxy are the sturdiest

been used to increase interfacial bond-

composites) such as polylactic acid reinforced thermosets for natural fibers.

ing between fiber and matrix

(PLA) have been emerging as a prom- The processing temperatures (ranging

[19,24,53,54]. Their extensive use is

ising thermoplastic biopolymer matrix. from 25°C to above 100°C) are below

due to manufacturing economy and

PLA has singular qualities, such as the degradation temperature of hemp

effective interaction of the anhydride

good transparency, glossy appearance, fibers (that begins around 150°C) [23].

with the fibers’ hydroxyl groups [55].

and high impact resistance. However, Therefore, the advantages of thermo-

The effect of maleated polypropylene PLA has some limitations, which are sets over thermoplastics are process-

on the mechanical properties of hemp associated with its inherent brittleness ing at a lower temperature, the avoid-

NCM-DECEMBER 2022

39