Page 36 - New Cloth Market December 2022 Digital Edition

P. 36

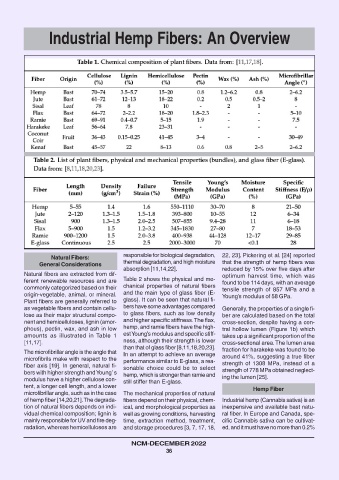

Industrial Hemp Fibers: An Overview

responsible for biological degradation, 22, 23]. Pickering et al. [24] reported

Natural Fibers:

thermal degradation, and high moisture that the strength of hemp fibers was

General Considerations

absorption [11,14,22]. reduced by 15% over five days after

Natural fibers are extracted from dif- optimum harvest time, which was

ferent renewable resources and are Table 2 shows the physical and me- found to be 114 days, with an average

commonly categorized based on their chanical properties of natural fibers tensile strength of 857 MPa and a

origin-vegetable, animal, or mineral. and the main type of glass fiber (E- Young’s modulus of 58 GPa.

Plant fibers are generally referred to glass). It can be seen that natural fi-

as vegetable fibers and contain cellu- bers have some advantages compared Generally, the properties of a single fi-

lose as their major structural compo- to glass fibers, such as low density ber are calculated based on the total

nent and hemicelluloses, lignin (amor- and higher specific stiffness. The flax, cross-section, despite having a cen-

phous), pectin, wax, and ash in low hemp, and ramie fibers have the high- tral hollow lumen (Figure 1b) which

amounts as illustrated in Table 1 est Young’s modulus and specific stiff- takes up a significant proportion of the

[11,17]. ness, although their strength is lower cross-sectional area. The lumen area

than that of glass fiber [8,11,18,20,23]. fraction for harakeke was found to be

The microfibrillar angle is the angle that

In an attempt to achieve an average around 41%, suggesting a true fiber

microfibrils make with respect to the

performance similar to E-glass, a rea- strength of 1308 MPa, instead of a

fiber axis [19]. In general, natural fi-

sonable choice could be to select strength of 778 MPa obtained neglect-

bers with higher strength and Young’ s

hemp, which is stronger than ramie and ing the lumen [25].

modulus have a higher cellulose con-

still stiffer than E-glass.

tent, a longer cell length, and a lower

Hemp Fiber

microfibrillar angle, such as in the case The mechanical properties of natural

of hemp fiber [14,20,21]. The degrada- fibers depend on their physical, chem- Industrial hemp (Cannabis sativa) is an

tion of natural fibers depends on indi- ical, and morphological properties as inexpensive and available bast natu-

vidual chemical composition; lignin is well as growing conditions, harvesting ral fiber. In Europe and Canada, spe-

mainly responsible for UV and fire deg- time, extraction method, treatment, cific Cannabis sativa can be cultivat-

radation, whereas hemicelluloses are and storage procedures [3, 7, 17, 18, ed, and it must have no more than 0.2%

NCM-DECEMBER 2022

36