Page 49 - New Cloth Market November 2022 Digital Edition

P. 49

Chitosan-Based Sustainable Textile Technology: Process, Mechanism, Innovation & Safety

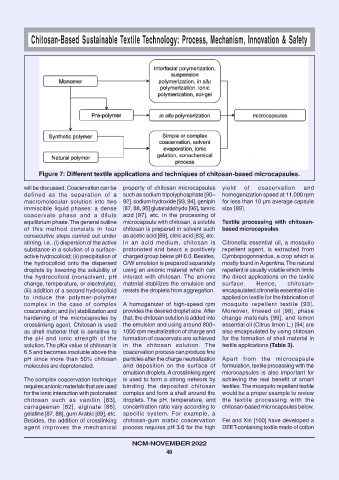

Figure 7: Different textile applications and techniques of chitosan-based microcapsules.

will be discussed. Coacervation can be property of chitosan microcapsules yield of coacervation and

defined as the separation of a such as sodium tripolyphosphate [90– homogenization speed at 11,000 rpm

macromolecular solution into two 92], sodium hydroxide [93, 94], genipin for less than 10 µm average capsule

immiscible liquid phases: a dense [87, 88, 95] glutaraldehyde [96], tannic size [89].

coacervate phase and a dilute acid [97], etc. In the processing of

equilibrium phase. The general outline microcapsule with chitosan, a soluble Textile processing with chitosan-

of this method consists in four chitosan is prepared in solvent such based microcapsules

consecutive steps carried out under as acetic acid [89], citric acid [83], etc.

stirring, i.e., (i) dispersion of the active In an acid medium, chitosan is Citronella essential oil, a mosquito

substance in a solution of a surface- protonated and bears a positively repellent agent, is extracted from

active hydrocolloid; (ii) precipitation of charged group below pH 6.0. Besides, Cymbopogonnardus, a crop which is

the hydrocolloid onto the dispersed O/W emulsion is prepared separately mostly found in Argentina. The natural

droplets by lowering the solubility of using an anionic material which can repellent is usually volatile which limits

the hydrocolloid (nonsolvent, pH interact with chitosan. The anionic the direct applications on the textile

change, temperature, or electrolyte); material stabilizes the emulsion and surface. Hence, chitosan-

(iii) addition of a second hydrocolloid resists the droplets from aggregation. encapsulated citronella essential oil is

to induce the polymer-polymer applied on textile for the fabrication of

complex in the case of complex A homogenizer of high-speed rpm mosquito repellent textile [93].

coacervation; and (iv) stabilization and provides the desired droplet size. After Moreover, linseed oil [98], phase

hardening of the microcapsules by that, the chitosan solution is added into change materials [99], and lemon

crosslinking agent. Chitosan is used the emulsion and using around 800– essential oil (Citrus limon L.) [94] are

as shell material that is sensitive to 1000 rpm neutralization of charge and also encapsulated by using chitosan

the pH and ionic strength of the formation of coacervate are achieved for the formation of shell material in

solution. The pKa value of chitosan is in the chitosan solution. The textile applications (Table 3).

6.5 and becomes insoluble above this coacervation process can produce fine

pH since more than 50% chitosan particles after the charge neutralization Apart from the microcapsule

molecules are deprotonated. and deposition on the surface of formulation, textile processing with the

emulsion droplets. A crosslinking agent microcapsules is also important for

The complex coacervation technique is used to form a strong network by achieving the real benefit of smart

requires anionic materials that are used binding the deposited chitosan textiles. The mosquito repellent textile

for the ionic interaction with protonated complex and form a shell around the would be a proper example to review

chitosan such as vanillin [83], droplets. The pH, temperature, and the textile processing with the

carrageenan [82], alginate [86], concentration ratio vary according to chitosan-based microcapsules below.

gelatine [87, 88], gum Arabic [89], etc. specific system. For example, a

Besides, the addition of crosslinking chitosan-gum arabic coacervation Fei and Xin [100] have developed a

agent improves the mechanical process requires pH 3.6 for the high DEET-containing textile made of cotton

NCM-NOVEMBER 2022

49