Page 41 - New Cloth Market November 2022 Digital Edition

P. 41

Chitosan-Based Sustainable Textile Technology: Process, Mechanism, Innovation & Safety

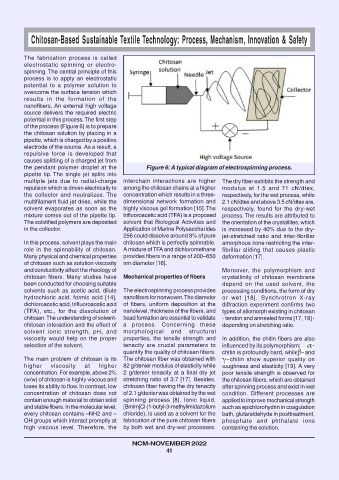

The fabrication process is called

electrostatic spinning or electro-

spinning. The central principle of this

process is to apply an electrostatic

potential to a polymer solution to

overcome the surface tension which

results in the formation of the

nanofibers. An external high voltage

source delivers the required electric

potential in this process. The first step

of the process (Figure 6) is to prepare

the chitosan solution by placing in a

pipette, which is charged by a positive

electrode of the source. As a result, a

repulsive force is developed that

causes splitting of a charged jet from

the pendant polymer droplet at the Figure 6: A typical diagram of electrospinning process.

pipette tip. The single jet splits into

multiple jets due to radial-charge interchain interactions are higher The dry fiber exhibits the strength and

repulsion which is driven electrically to among the chitosan chains at a higher modulus at 1.5 and 71 cN/dtex,

the collector and neutralizes. The concentration which results in a three- respectively, for the wet process, while

multifilament fluid jet dries, while the dimensional network formation and 2.1 cN/dtex and above 3.5 cN/dtex are,

solvent evaporates as soon as the highly viscous gel formation [15]. The respectively, found for the dry-wet

mixture comes out of the pipette tip. trifluoroacetic acid (TFA) is a proposed process. The results are attributed to

The solidified polymers are deposited solvent that Biological Activities and the orientation of the crystallites, which

in the collector. Application of Marine Polysaccharides is increased by 40% due to the dry-

256 could dissolve around 8% of pure jet-stretched ratio and inter-fibrillar

In this process, solvent plays the main chitosan which is perfectly spinnable. amorphous zone restricting the inter-

role in the spinnability of chitosan. A mixture of TFA and dichloromethane fibrillar sliding that causes plastic

Many physical and chemical properties provides fibers in a range of 200–650 deformation [17].

of chitosan such as solution viscosity nm diameter [16].

and conductivity affect the rheology of Moreover, the polymorphism and

chitosan fibers. Many studies have Mechanical properties of fibers crystallinity of chitosan membrane

been conducted for choosing suitable depend on the used solvent, the

solvents such as acetic acid, dilute The electrospinning process provides processing conditions, the form of dry

hydrochloric acid, formic acid [14], nanofibers for nonwoven. The diameter or wet [18]. Synchrotron X-ray

dichloroacetic acid, trifluoroacetic acid of fibers, uniform deposition at the diffraction experiment confirms two

(TFA), etc., for the dissolution of nanolevel, thickness of the fibers, and types of allomorph existing in chitosan

chitosan. The understanding of solvent- bead formation are essential to validate - tendon and annealed forms [17, 18] -

chitosan interaction and the effect of a process. Concerning these depending on stretching ratio.

solvent ionic strength, pH, and morphological and structural

viscosity would help on the proper properties, the tensile strength and In addition, the chitin fibers are also

selection of the solvent. tenacity are crucial parameters to influenced by its polymorphism;

quantify the quality of chitosan fibers. chitin is profoundly hard, while and

The main problem of chitosan is its The chitosan fiber was obtained with chitin show superior quality on

higher viscosity at higher 82 g/denier modulus of elasticity while toughness and elasticity [19]. A very

concentration. For example, above 2% 2 g/denier tenacity at a final dry jet poor tensile strength is observed for

(w/w) of chitosan is highly viscous and stretching ratio of 3.7 [17]. Besides, the chitosan fibers, which are obtained

loses its ability to flow. In contrast, low chitosan fiber having the dry tenacity after spinning process and exist in wet

concentration of chitosan does not of 2.1 g/denier was obtained by the wet condition. Different processes are

contain enough material to obtain solid spinning process [8]. Ionic liquid, applied to improve mechanical strength

and stable fibers. In the molecular level, [Bmim]Cl (1-butyl-3-methylimidazolium such as epichlorohydrin in coagulation

every chitosan contains –NH2 and – chloride), is used as a solvent for the bath, glutaraldehyde in posttreatment,

OH groups which interact promptly at fabrication of the pure chitosan fibers phosphate and phthalate ions

high viscous level. Therefore, the by both wet and dry-wet processes. containing the solution.

NCM-NOVEMBER 2022

41