Page 39 - New Cloth Market November 2022 Digital Edition

P. 39

Chitosan-Based Sustainable Textile Technology: Process, Mechanism, Innovation & Safety

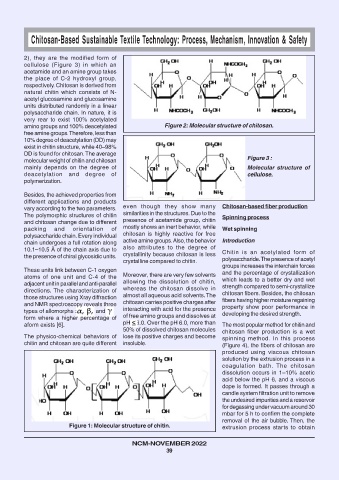

2), they are the modified form of

cellulose (Figure 3) in which an

acetamide and an amine group takes

the place of C-2 hydroxyl group,

respectively. Chitosan is derived from

natural chitin which consists of N-

acetyl glucosamine and glucosamine

units distributed randomly in a linear

polysaccharide chain. In nature, it is

very rear to exist 100% acetylated

amino groups and 100% deacetylated Figure 2: Molecular structure of chitosan.

free amine groups. Therefore, less than

10% degree of deacetylation (DD) may

exist in chitin structure, while 40–98%

DD is found for chitosan. The average

molecular weight of chitin and chitosan Figure 3 :

mainly depends on the degree of Molecular structure of

deacetylation and degree of cellulose.

polymerization.

Besides, the achieved properties from

different applications and products

even though they show many Chitosan-based fiber production

vary according to the two parameters.

similarities in the structures. Due to the

The polymorphic structures of chitin Spinning process

presence of acetamide group, chitin

and chitosan change due to different

mostly shows an inert behavior, while

packing and orientation of Wet spinning

chitosan is highly reactive for free

polysaccharide chain. Every individual

active amine groups. Also, the behavior Introduction

chain undergoes a full rotation along

also attributes to the degree of

10.1–10.5 Å of the chain axis due to

crystallinity because chitosan is less Chitin is an acetylated form of

the presence of chiral glycosidic units.

crystalline compared to chitin. polysaccharide. The presence of acetyl

groups increases the interchain forces

These units link between C-1 oxygen

Moreover, there are very few solvents and the percentage of crystallization

atoms of one unit and C-4 of the

allowing the dissolution of chitin, which leads to a better dry and wet

adjacent unit in parallel and anti-parallel

whereas the chitosan dissolve in strength compared to semi-crystallize

directions. The characterization of

almost all aqueous acid solvents. The chitosan fibers. Besides, the chitosan

those structures using Xray diffraction

chitosan carries positive charges after fibers having higher moisture regaining

and NMR spectroscopy reveals three

interacting with acid for the presence property show poor performance in

types of allomorphs : and

of free amino groups and dissolves at developing the desired strength.

form where a higher percentage of

pH 6.0. Over the pH 6.0, more than

aform exists [6]. The most popular method for chitin and

50% of dissolved chitosan molecules

chitosan fiber production is a wet

The physico-chemical behaviors of lose its positive charges and become

spinning method. In this process

chitin and chitosan are quite different insoluble.

(Figure 4), the fibers of chitosan are

produced using viscous chitosan

solution by the extrusion process in a

coagulation bath. The chitosan

dissolution occurs in 1–10% acetic

acid below the pH 6, and a viscous

dope is formed. It passes through a

candle system filtration unit to remove

the undesired impurities and a reservoir

for degassing under vacuum around 30

mbar for 5 h to confirm the complete

removal of the air bubble. Then, the

Figure 1: Molecular structure of chitin. extrusion process starts to obtain

NCM-NOVEMBER 2022

39