Page 38 - New Cloth Market November 2022 Digital Edition

P. 38

Chitosan-Based Sustainable Textile Technology:

Process, Mechanism,

Innovation, and Safety

Jagadish Roy, Fabien Salaün, Stéphane Giraud, Ada Ferri and Jinping Guan

http://dx.doi.org/10.5772/65259

Abstract

This paper reviews relevant findings regarding the activities and contributions of chitosan in different

textile processing following the varieties of process, mechanism, and applications. Chitosan is a better

candidate in both aspects of biodegradability and effciency instead of synthetic polymers. The technical

and scientific discussions behind the role of chitosan in all the processes and treatments have been

explored in the paper. Over the last few years, enormous efiorts and challenges are being practiced in

research and industry to design and development of eco-friendly and sustainable technologies. Therefore,

the chapter emphasizes on chitosan-based formulations of fibers, fabrics, coatings, and functional textiles.

Keywords: chitin, chitosan, textile, fiber, fabric, antibacterial, nanofibers, electrospun

Introduction

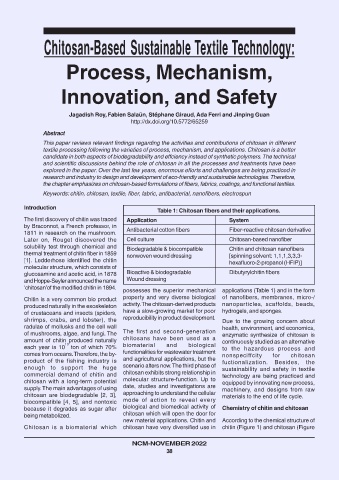

Table 1: Chitosan fibers and their applications.

The first discovery of chitin was traced Application System

by Braconnot, a French professor, in

Antibacterial cotton fibers Fiber-reactive chitosan derivative

1811 in research on the mushroom.

Later on, Rouget discovered the Cell culture Chitosan-based nanofiber

solubility test through chemical and

Biodegradable & biocompatible Chitin and chitosan nanofibers

thermal treatment of chitin fiber in 1859

nonwoven wound dressing [spinning solvent: 1,1,1,3,3,3-

[1]. Ledderhose identified the chitin

hexafluoro-2-propanol (HFIP)]

molecular structure, which consists of

glucosamine and acetic acid, in 1878 Bioactive & biodegradable Dibutyrylchitin fibers

and Hoppe-Seyler announced the name Wound dressing

‘chitosan’of the modified chitin in 1894.

possesses the superior mechanical applications (Table 1) and in the form

Chitin is a very common bio product property and very diverse biological of nanofibers, membranes, micro-/

produced naturally in the exoskeleton activity. The chitosan-derived products nanoparticles, scaffolds, beads,

of crustaceans and insects (spiders, have a slow-growing market for poor hydrogels, and sponges.

shrimps, crabs, and lobster), the reproducibility in product development. Due to the growing concern about

radulae of mollusks and the cell wall health, environment, and economics,

of mushrooms, algae, and fungi. The The first and second-generation enzymatic synthesize of chitosan is

amount of chitin produced naturally chitosans have been used as a continuously studied as an alternative

10

each year is 10 ton of which 70% biomaterial and biological to the hazardous process and

comes from oceans. Therefore, the by- functionalities for wastewater treatment nonspeciffcity for chitosan

product of the fishing industry is and agricultural applications, but the fuctionalization. Besides, the

enough to support the huge scenario alters now. The third phase of sustainability and safety in textile

commercial demand of chitin and chitosan exhibits strong relationship in technology are being practiced and

chitosan with a long-term potential molecular structure-function. Up to equipped by innovating new process,

supply. The main advantages of using date, studies and investigations are machinery, and designs from raw

chitosan are biodegradable [2, 3], approaching to understand the cellular materials to the end of life cycle.

biocompatible [4, 5], and nontoxic mode of action to reveal every

because it degrades as sugar after biological and biomedical activity of Chemistry of chitin and chitosan

being metabolized. chitosan which will open the door for

new material applications. Chitin and According to the chemical structure of

Chitosan is a biomaterial which chitosan have very diversified use in chitin (Figure 1) and chitosan (Figure

NCM-NOVEMBER 2022

38