Page 21 - New Cloth Market December 2022 Digital Edition

P. 21

water are precipitated. Moreover, precipitates of To study the Washing-off efficiency of Sarakol-

calcium and magnesium soaps adhere to the fab- AD in hard water

rics. The sticky precipitate adheres on the fabric

AGES

giving spots and streaks which will eventually ham- Dyeing of cotton fabric was carried out with 6% C.I.

per quality of final fabric. Therefore, the lack of right Reactive Red 152 as per the standard procedure.

firsttime dyeing are very frequent and leads to the After the completion of dyeing process, the fabrics

necessity of corrective reprocessing such as re- were subjected for washing off treatment with Sara-

dyeing or stripping which unnecessarily increases kol-AD. The washing off efficiency of the fabrics were

the additional consumption of resources such as then evaluated by performing the laundry test in 150

dyestuff and auxiliaries, time, and also increases ppm calcium hardness. The fabrics were run in the

the cost of production. Corrective reprocessing also 150ppm hard water at 90°C for 30 min. keeping MLR

consumes additional water, energy and generates - 1:20. The staining on adjacent white fabric was

more effluent. With this background, Sarex has de- checked and assessed.

veloped a multifunctional auxiliary, Sarakol-AD,

Product Performance Data

which will effectively perform in presence of hard

water. Sarakol-AD, to some extent, will help to Dispersing efficiency in presence of Hard water

achieve the right first-time dyeing. It's use at vari-

ous stages in textile processing will save the extra

EXECUTIVE P

washing/rinsing baths which would otherwise be man-

datory for wet processing operations in hard water.

Unique Features

* Sarakol-AD is a washing off agent for reactive

dyed and printed cellulosic fibres and their blends

effective in presence of electrolyte.

* It improves the solubility of reactive dyes under

adverse conditions of dyeing’s such as low li-

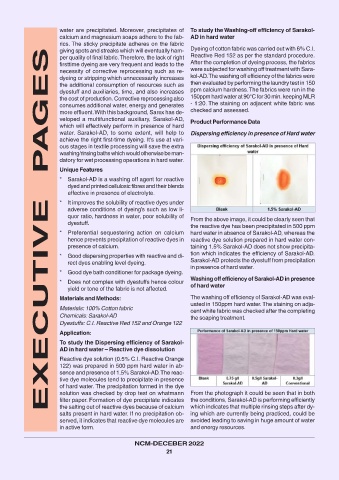

quor ratio, hardness in water, poor solubility of From the above image, it could be clearly seen that

dyestuff.

the reactive dye has been precipitated in 500 ppm

* Preferential sequestering action on calcium hard water in absence of Sarakol-AD, whereas the

hence prevents precipitation of reactive dyes in reactive dye solution prepared in hard water con-

presence of calcium. taining 1.5% Sarakol-AD does not show precipita-

tion which indicates the efficiency of Sarakol-AD.

* Good dispersing properties with reactive and di-

Sarakol-AD protects the dyestuff from precipitation

rect dyes enabling level dyeing.

in presence of hard water.

* Good dye bath conditioner for package dyeing.

Washing off efficiency of Sarakol-AD in presence

* Does not complex with dyestuffs hence colour

of hard water

yield or tone of the fabric is not affected.

Materials and Methods: The washing off efficiency of Sarakol-AD was eval-

uated in 150ppm hard water. The staining on adja-

Materials: 100% Cotton fabric

cent white fabric was checked after the completing

Chemicals: Sarakol-AD the soaping treatment.

Dyestuffs: C.I. Reactive Red 152 and Orange 122

Application:

To study the Dispersing efficiency of Sarakol-

AD in hard water – Reactive dye dissolution

Reactive dye solution (0.5% C.I. Reactive Orange

122) was prepared in 500 ppm hard water in ab-

sence and presence of 1.5% Sarakol-AD. The reac-

tive dye molecules tend to precipitate in presence

of hard water. The precipitation formed in the dye

solution was checked by drop test on whatmann From the photograph it could be seen that in both

filter paper. Formation of dye precipitate indicates the conditions, Sarakol-AD is performing efficiently

the salting out of reactive dyes because of calcium which indicates that multiple rinsing steps after dy-

salts present in hard water. If no precipitation ob- ing which are currently being practiced, could be

served, it indicates that reactive dye molecules are avoided leading to saving in huge amount of water

in active form. and energy resources.

NCM-DECEBER 2022

21