Page 16 - New Cloth Market December 2022 Digital Edition

P. 16

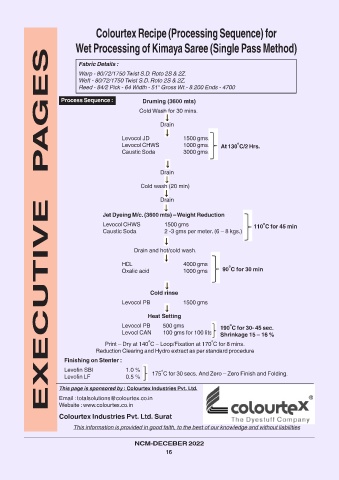

Colourtex Recipe (Processing Sequence) for

Wet Processing of Kimaya Saree (Single Pass Method)

AGES

Fabric Details :

Warp - 80/72/1750 Twist S.D. Roto 2S & 2Z.

Weft - 80/72/1750 Twist S.D. Roto 2S & 2Z.

Reed - 84/2 Pick - 64 Width - 51" Gross Wt.- 8.200 Ends - 4700

Process Sequence : Druming (3600 mts)

Cold Wash for 30 mins.

Drain

Levocol JD 1500 gms.

o

Levocol CHWS 1000 gms. At 130 C/2 Hrs.

EXECUTIVE P

Caustic Soda 3000 gms.

Drain

Cold wash (20 min)

Drain

Jet Dyeing M/c. (3600 mts) – Weight Reduction

o

Levocol CHWS 1500 gms 110 C for 45 min

Caustic Soda 2 -3 gms per meter. (6 – 8 kgs.)

Drain and hot/cold wash.

HCL 4000 gms o

Oxalic acid 1000 gms 90 C for 30 min

Cold rinse

Levocol PB 1500 gms

Heat Setting

Levocol PB 500 gms 190 C for 30- 45 sec.

o

Levocl CAN 100 gms for 100 lits Shrinkage 15 – 16 %

o o

Print – Dry at 140 C – Loop/Fixation at 170 C for 8 mins.

Reduction Clearing and Hydro extract as per standard procedure

Finishing on Stenter :

Levofin SBI 1.0 % 175 C for 30 secs. And Zero – Zero Finish and Folding.

o

Levofin LF 0.5 %

This page is sponsored by : Colourtex Industries Pvt. Ltd.

Email : [email protected]

Website : www.colourtex.co.in

Colourtex Industries Pvt. Ltd. Surat

This information is provided in good faith, to the best of our knowledge and without liabilities

NCM-DECEBER 2022

16