Page 47 - New Cloth Market December 2022 Digital Edition

P. 47

Industrial Hemp Fibers: An Overview

directional Alfa-Polyester Composite. 97. Mohanty, A.K.; Misra, M.; Drzal, L.T. Sustainable Bio-Composites from Renew-

Compos. Sci. Technol. 2007, 67, 140– able Resources: Opportunities and Challenges in the Green Materials World. J.

147. [CrossRef] Polym. Environ. 2002, 10, 19–26. [CrossRef]

88. Lu, N.; Oza, S. A Comparative Study 98. Ahmad, F.; Choi, H.S.; Park, M.K. A Review: Natural Fiber Composites Selection

of the Mechanical Properties of Hemp in View of Mechanical, Light Weight, and Economic Properties. Macromol. Mater.

Fiber with Virgin and Recycled High Eng. 2015, 300, 10–24. [CrossRef]

Density Polyethylene Matrix. Com-

pos. Part B Eng. 2013, 45, 1651– To view all the Cross References [CrossRef],

1656. [CrossRef] please scan this QR code.

89. Dhakal, H.N.; Zhang, Z.Y.; Richard- This article is an open access article distributed under

son, M.O.W. Effect of Water Absorp- the terms and conditions of the Creative Commons:

tion on the Mechanical Properties of Manaia, J.P.; Manaia, A.T.; Rodriges, L. Industrial Hemp

Hemp Fibre Reinforced Unsaturated

Fibers: An Overview. Fibers 2019, 7, 106. https://doi.org/

Polyester Composites. Compos. Sci.

10.3390/fib7120106

Technol. 2007, 67, 1674–1683.

[CrossRef]

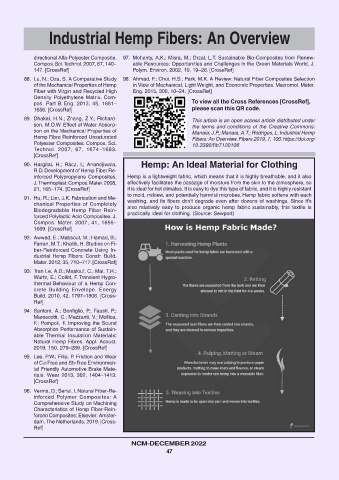

90. Hargitai, H.; Rácz, I.; Anandjiwala, Hemp: An Ideal Material for Clothing

R.D. Development of Hemp Fiber Re-

inforced Polypropylene Composites. Hemp is a lightweight fabric, which means that it is highly breathable, and it also

J. Thermoplast. Compos. Mater. 2008, effectively facilitates the passage of moisture from the skin to the atmosphere, so

21, 165–174. [CrossRef] it is ideal for hot climates. It is easy to dye this type of fabric, and it is highly resistant

to mold, mildew, and potentially harmful microbes. Hemp fabric softens with each

91. Hu, R.; Lim, J.K. Fabrication and Me-

washing, and its fibers don't degrade even after dozens of washings. Since it's

chanical Properties of Completely

Biodegradable Hemp Fiber Rein- also relatively easy to produce organic hemp fabric sustainably, this textile is

practically ideal for clothing. (Source: Sewport)

forced Polylactic Acid Composites. J.

Compos. Mater. 2007, 41, 1655–

1669. [CrossRef]

92. Awwad, E.; Mabsout, M.; Hamad, B.;

Farran, M.T.; Khatib, H. Studies on Fi-

ber-Reinforced Concrete Using In-

dustrial Hemp Fibers. Constr. Build.

Mater. 2012, 35, 710–717. [CrossRef]

93. Tran Le, A.D.; Maalouf, C.; Mai, T.H.;

Wurtz, E.; Collet, F. Transient Hygro-

thermal Behaviour of a Hemp Con-

crete Building Envelope. Energy

Build. 2010, 42, 1797–1806. [Cross-

Ref]

94. Santoni, A.; Bonfiglio, P.; Fausti, P.;

Marescotti, C.; Mazzanti, V.; Mollica,

F.; Pompoli, F. Improving the Sound

Absorption Performance of Sustain-

able Thermal Insulation Materials:

Natural Hemp Fibres. Appl. Acoust.

2019, 150, 279–289. [CrossRef]

95. Lee, P.W.; Filip, P. Friction and Wear

of Cu-Free and Sb-Free Environmen-

tal Friendly Automotive Brake Mate-

rials. Wear 2013, 302, 1404–1413.

[CrossRef]

96. Verma, D.; Senal, I. Natural Fiber-Re-

inforced Polymer Composites: A

Comprehensive Study on Machining

Characteristics of Hemp Fiber-Rein-

forced Composites; Elsevier: Amster-

dam, The Netherlands, 2019. [Cross-

Ref]

NCM-DECEMBER 2022

47