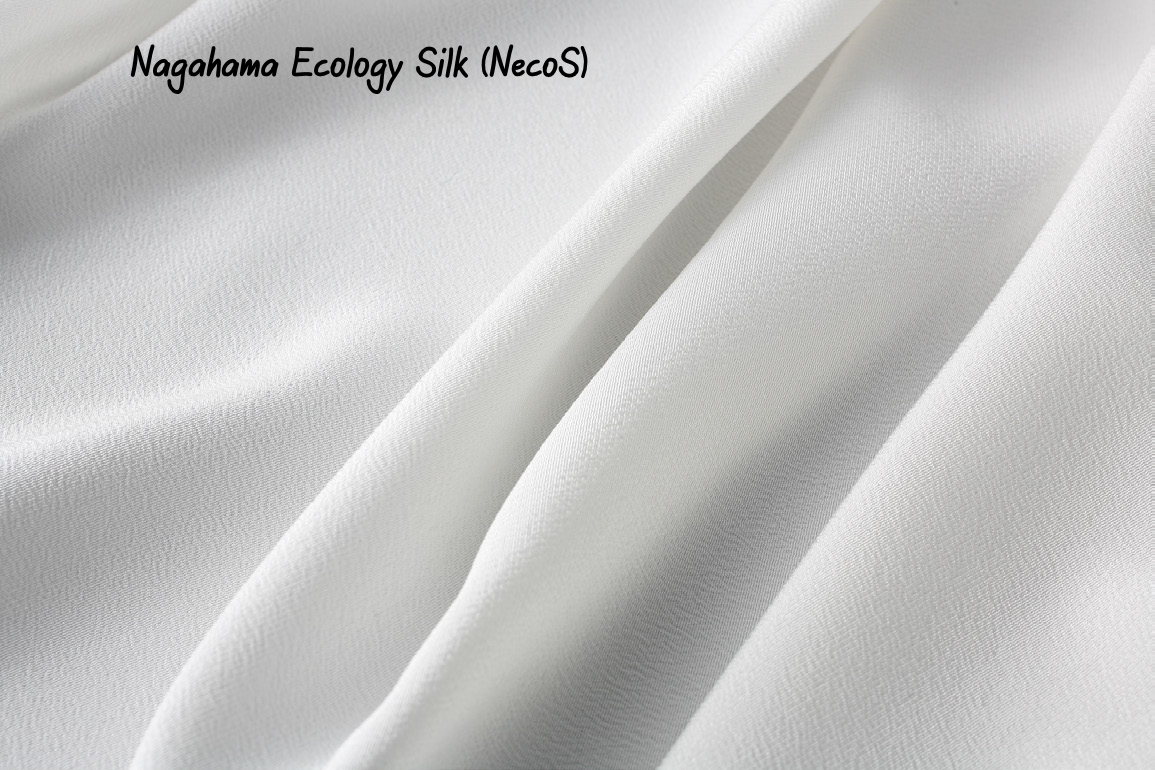

Nagahama Ecology Silk NecoS. Chirimen crepe produced with a chemical free degumming process.

The 3-Day International Sustainable Fashion Expo

Autumn Dates Venue Featured Product

18 (Mon)-20 (Wed) October 2021 (3days) 10:00-17:00

Tokyo Big Sight, West Exhibition Halls [A2-40].

Sustainable silk fabrics from Yoshimasa Orimono Co.,Ltd.

Material NecoS [Nagahama Ecology Silk]:

Yugen Co.,Ltd, organizer of JTEX, a trade organization dedicated to international markets, is pleased to introduce NecoS (Nagahama Ecology Silk), a silk material developed by Yoshimasa Orimono Co.,Ltd, at “the International Sustainable Fashion Expo Autumn”. NecoS reduces carbon dioxide emissions by 3 kg per suit, compared to a silk suit produced using conventional methods.

With the globalization of the supply chain, there is a growing awareness that the textile industry is one of the most concerned with sustainability in terms of waste, water and energy consumption, pesticides, plastics, working conditions and human rights. Through the development of NecoS, we hope to contribute to reducing the use of resources in the fashion supply chain.

The innovative NecoS technology reduces carbon dioxide emissions by lowering the amount of water and heavy oil consumption, while reducing the need for soda ash.

patent application has been filed for this technology along with Shiga Prefecture.

- By eliminating the use of soda ash, carbon dioxide emissions are reduced by 8.7 kilogram s per 200 square meters of normal degumming volume per batch.

- It also reduces the use of water and heavy oil. By replacing boiling water with room temperature water for the pre-treatment and finishing process, the carbon dioxide emission is reduced by another 93 kg.

- Thus, the total reduction in carbon dioxide emissions is 101.7 kg.

- In addition, the method also makes it possible to cut down on: Water:2,000 liters; Heavy oil:17 liters; Soda ash :22 kg

These figures were calculated by the Northeast Industrial Reaearch Center of Shiga Prefecture.

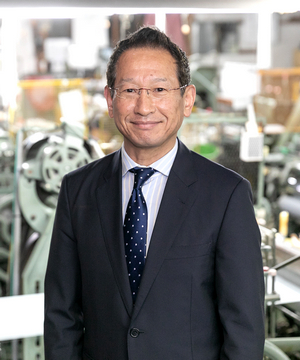

Picture of shop floor of Yoshimasa Orimono Co.,Ltd.

The journey to the Development

Silk fabric is made using a process called “degumming” to remove sericin, the natural protective molecule of silk yarn. Sericin is also used in cosmetics. In the conventional method, we applied hot, slightly alkaline water from Lake Biwa. In the past, we used to use the water as if it were unlimited. But when we finally realized what was at stake, we decided to take action.

It was very challenging to go back to the ancient method, because of the costs and the way to implement it in mass production. But we finally succeeded in commercializing NecoS last year. The production volume is still limited, but we have already started selling it in Europe, where sustainability is considered one of the priorities.

Since it is made without any bleaching agent, you can fully enjoy the natural shine, beauty and touch of silk.

Message from Kazuo Yoshida, President

I am Kazuo Yoshida, president of Yoshimasa Orimono Co.,Ltd, a textile manufacturer that has been operating for 95 years in Nagahama. As a weaving manufacturer from a small town, we have worked hard to maintain our business despite the current difficult market situation. In recent years, we have begun to actively engage in sustainable development initiatives. To be honest, the more I learn about sustainability, the more I realize how difficult it is to put it into practice. However, we have met a number of people and stakeholders who share and support our company’s initiative along this journey. We would like as many people as possible to see what a small company like ours has accomplished so far. We also hope to hear the comments and opinions of visitors.

Hamachirimen manufactured from silk

Yoshimasa Orimono is a hamachirimen crepe manufacturer. Hamachirimen is one of the most important local industries in Nagahama City, the land of the great lake. The current president is also the chairperson of the Hamachirimen Industrial Cooperative. The company inherited the spirit of sustainability from the Omi merchants, who adhered to the principle of “eampo yoshi”. It has also revived the production of “Maru tsumugi”, a type of pongee with a traditional material made from lint.

Hamachirimen is manufactured from silk. The moisture absorption capacity of silk is 1.3 to 1.5 times that of cotton, and the moisture desorption capacity is also approximately 1.3 times that of cotton. These properties of silk fabrics have given rise to the theory of “quick absorption” and “quick-drying” of sweat, which keep you cool in summer, and warm in winter since air is trapped in the gaps between the intricate fibers, even though the fabric is thin.

About Yoshimasa Orimono Co. Ltd ,.

President Yosnida’s vision for sustainability as a chirimen silk crepe manufacturing company, a local industry.

President Kazuo Yoshida

The company was first formed in 1927 and the current representative is the third generation of the founding family. It’s a manufacturer of Hamachilimen silk crepe, and currently have 13 employees. The distinctive feature of the company is that they carry out all processes in-house, from the purchase of raw silk yarn to the final product.

Fabric production involves 38 processes, none of which can be overlooked, and each process involves the skills of our craftsmen.

Nagahama City faces Lake Biwa to the west and the Ibuki mountain range rises to the east. Nagahama is famous for its heavy snowfall, which used to accumulate up to two or three meters. Silkworm cultivation flourished in the Ibuki Mountain area, and then developed into silk weaving in Nagahama. Silk weaving requires humidity and the degumming process requires a large amount of water. But above all, the area has taken advantage of its geographical location. The city is very close to Kyoto, a place of great consumption. Raw materials, moisture, water and adjacent markets have contributed to its development.

We also produce sustainable silk materials. Our origins lie in the efficient use of the “lint” produced during the weaving of chirimen crepe, which is collected and twisted to make silk thread, known as rolled thread in the region. The result is a very strong fabric that does not tear or fray, even if you sit on it every day, which is why it has been used primarily for cushions. Needless to say, silk has exceptional heat retention properties, making it an indispensable indoor item in cold and snowy regions in winter. After World War II, there was a period called “Gachaman”, during which the weaving industry flourished. This is how we started the production of crepe.

We excel in creative crepe making and our kimonos are appreciated by many people, including living national treasures. Today, we are also expanding our business internationally. We have received praise from European luxury brands and continue to do business with them.

How did you come to start developing sustainable materials?

About five years ago, we started to sell our products to luxury brands in Europe with the support of JETRO. There, I was asked if I had any sustainable materials, but I didn’t understand what they meant at all. We had been selling the material for scarves, dresses and jackets, so we left the issue aside for a moment. But one day, a buyer told me, “If you don’t take visible action by 2025, you won’t be able to do business with us in the future.” That was the start.

So it was more like a necessity than a voluntary decision?

That’s exactly right. One of our buyers gave us a document showing the guidelines for sustainable materials, but it was huge and in English. When I was puzzling over it, JE T R O gave me an advice or rather an obvious comment, “We have to start from what we can do.

How did you proceed in understanding and dealing with sustainability?

In the beginning, we understood that if we produced organic, recycled, low-carbon emission, and low-water-use materials, we would be sustainable, and we have been working on developing such materials. In fact, what we are going to present in this trade show is the result of our efforts.

However, in the course of my learning, I have realized that sustainability is not only about the materials we provide. As a whole, we still have a long way to go.

Is there anything else you can propose other than NecoS?

We also propose “Recycled silk “(fabric made from recycled silk yarn). This is a material that can be considered as our quintessence. Shiga prefecture, also known as the land of the great lake, is the birthplace of Omi merchants, who are famous for the ‘San p cy o sh i’ principle (‘good in three directions’ meaning that commerce should not only benefit the buyer and the seller but also society as a whole). In Japanese, there is also an expression called “shimatsu” which means to cherish things. This philosophy is reflected in the spirit of cherishing and using up all the silk yarns that the silkworms, which took so much time and effort to grow, risked their lives to produce.

In the past, there were businesses that collected “lint” and spinning it into thread. It used to be an important side job for farmers. Nowadays, due to the aging of the population, there are no longer any people doing it, but we have succeeded in recreating such yarn by using industrial spinning machines and mixing it with other waste silk materials, although it is not 100% made from “lint”.

You are going to present the material you have developed at the exhibition in Tokyo.

It is important to receive orders, but the research aspect is also very important. As a local weaving company, it is still challenging for us to fully understand how to address sustainability in fashion. I believe that in order to achieve sustainability, it is essential for all participants to understand and implement actions.

Since I started my research, I have realized that there are many things that need to be improved within our company, and I would like to increase the number of people who share the idea while openly talking about them.

What are your future goals?

First of all, I think it is important to inform people about the production area and the advantages of chirimen crepe. In Europe, crepe is highly evaluated for its durability, easiness of maintenance, and other practical aspects, while in Japan, partly due to our lack of effort, crepe is easily regarded as a fabric for kimono and is not well recognized in the fashion industry.

However, we would like people to realize the value of crepe as a sustainable material, not only in the fashion industry, but also in line with the new value changes that are being shared on a global scale. Chirimen, which has been handed down to us by our ancestors, is highly practical and durable thanks to its strong twisted yarn. In the past, this fabric was passed down from parents to offspring by “rewashing” and “re-dyeing”. Because it was so durable, it could be used for daily wear.

We are determined to continue our transformation as a sustainable company through the production of chirimen crepe.

Yoshimasa Orimono NecoS Press Conference [Sustainable Silk]

(Courtesy: Yoshimasa Orimono Co., Ltd.)