AFM leveraged Gerber’s integrated solution to enter the competitive exports market. AFM Distribution Sh.p.k. is a manufacturing firm that specializes in the production of top quality work wear garments primarily for consumption in the European market. AFM produces work wear and professional uniforms used by private and public industry sectors

AFM leveraged Gerber’s integrated solution to enter the competitive exports market. AFM Distribution Sh.p.k. is a manufacturing firm that specializes in the production of top quality work wear garments primarily for consumption in the European market. AFM produces work wear and professional uniforms used by private and public industry sectors

Thursday, October 15, 2020:

AFM Distribution, a successful, Albanian workwear company, is leveraging Gerber Technology’s integrated solution to reduce costs, labor and material waste so they can expand their business. As a company who prides themselves on quality manufacturing, their ability to meet deadlines and their commitment to treating people as an asset, AFM knew the only choice to help them was Gerber Technology. Since implementing Gerber’s solutions, AFM has improved their profitability by approximately 25% which has enabled them to invest in more staff training and specialization.

“Many people believe that technology is going to replace their employees, but as we’ve seen with AFM, that’s not the case at all,” said Richard Jessup of Gerber Technology. “By correctly leveraging technology, AFM was actually able to improve the livelihood of their employees by adding to their skillset and giving them opportunities to grow. We are proud to help AFM not only streamline their production but also empower them to create jobs.”

Over the last several years, AFM Distribution has experienced tremendous growth and is looking to enter the competitive export market. In order for AFM to successfully expand their company and ensure they are offering the best quality and price for each of the 60,000 garments they develop per month, they needed a solution that was able to increase efficiency, reduce time to market and cut costs.

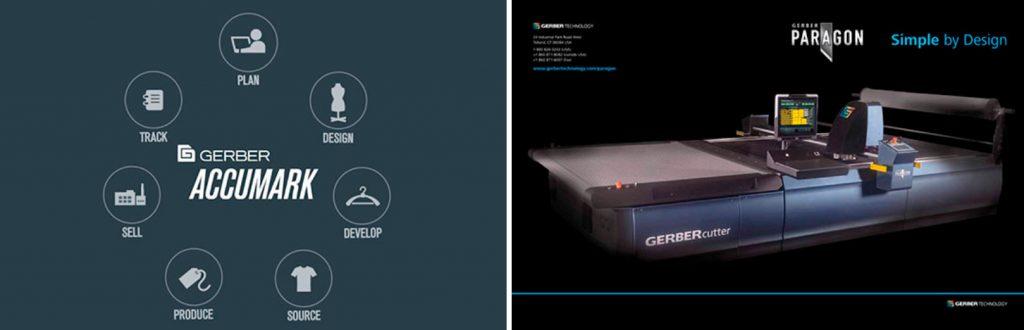

AFM’s manufacturing site in Vora is equipped with the GERBERspreader™ XLs50, the Gerber Paragon® HX, and Gerber’s industry-leading software solutions: AccuMark®, AccuNest™ and AccuPlan™. Since AFM uses expensive fabrics and materials, it’s critical they maximize material usage and cut with absolute precision. With the powerful combination of AccuPlan and AccuNest, AFM is able to digitally send Cut Plan solutions, which include multiple markers, fabrics, colors and corresponding spreads and ply count, to quickly produce and track down the cutting efficiency of thousands of garments. Since implementing Gerber’s powerful design and production tools, AFM has been able to deliver as many as 1,800 parts per shift, assuring quality from the first layer of fabric to the last while saving money and improving material utilization.

Gerber technologies at work in the production plant of AFM Distribution: AFM Distribution leverage integrated Gerber Paragon with Gerber’s AccuMark® CAD and automated spreading systems to efficiently fulfill production quotas.

Gerber technologies at work in the production plant of AFM Distribution: AFM Distribution leverage integrated Gerber Paragon with Gerber’s AccuMark® CAD and automated spreading systems to efficiently fulfill production quotas.

“The GERBERcutter® provides maximum precision, especially when cutting notches and holes,” said Ardiana Karakashi, AFM’s finance director. “This is particularly critical as the company manufactures workwear which can have as many as 200 notches. By leveraging Gerber, the cutting quality is assured from the first layer of fabric to the last. Moreover, we can rely on the first-rate technical support provided by Gerber Italia.”

“The GERBERcutter® provides maximum precision, especially when cutting notches and holes,” said Ardiana Karakashi, AFM’s finance director. “This is particularly critical as the company manufactures workwear which can have as many as 200 notches. By leveraging Gerber, the cutting quality is assured from the first layer of fabric to the last. Moreover, we can rely on the first-rate technical support provided by Gerber Italia.”

About Gerber Technology

Gerber Technology delivers industry-leading software and automation solutions that help apparel and industrial customers improve their manufacturing and design processes and more effectively manage and connect the supply chain, from product development and production to retail and the end customer. With customers in 134 countries, Gerber Technology has a global team of passionate experts to support companies in apparel and accessories, personal protective equipment, home and leisure, transportation, packaging and sign and graphics industries.

Based in Connecticut in the USA, Gerber Technology is owned by AIP, a New York-based, global private equity firm specializing in the technology sector and has more than $3.0 billion assets under management. The company develops and manufactures its products from various locations in the United States and Canada and has additional manufacturing capabilities in China.