Baldwin installs six precision spray systems in 60 days for textile manufacturers

Baldwin installs six precision spray systems in 60 days for textile manufacturers

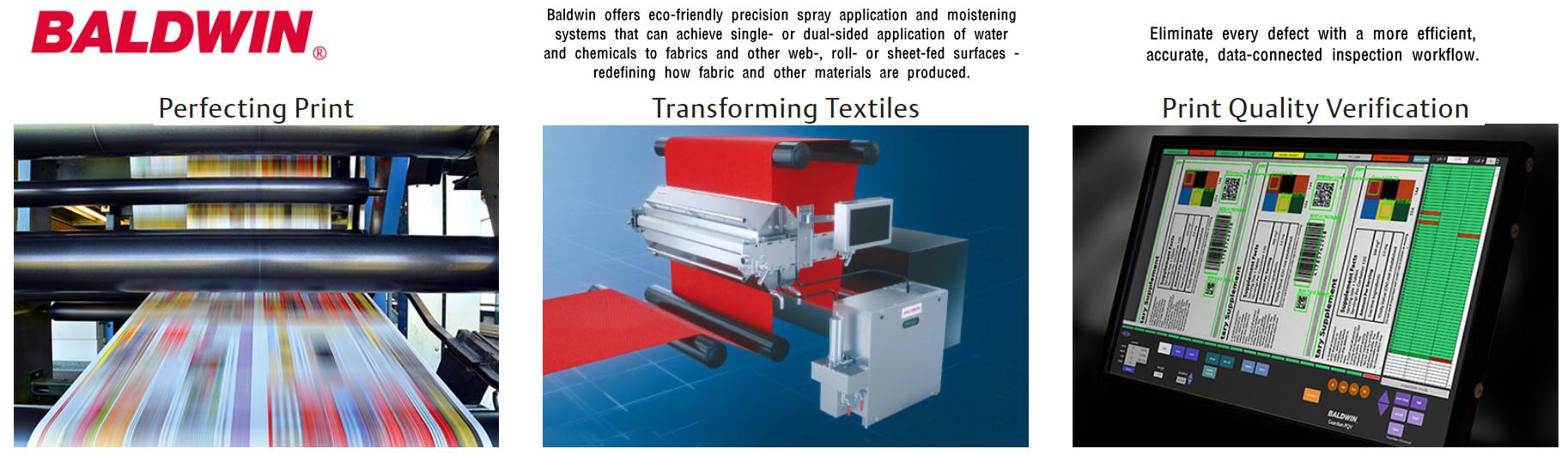

Baldwin Technology Company Inc. has successfully installed six new fabric finishing and sanforizing precision spray systems in the US and Turkey. Despite the COVID-19 pandemic, the installations were completed in just 60 days, thanks to close collaboration between onsite Baldwin textile team members, local agents and remote support from the company’s product and technology center in Sweden.

For textiles, non-wovens and technical textiles, Baldwin’s precision spray technology processes a wide range of low-viscosity water-based chemicals, such as softeners, anti-microbial agents, water repellents, oil repellents, flame retardants and more. These systems enable fabric producers to significantly reduce chemical and water consumption, while speeding up production times and eliminating production steps, including drying and bath changeovers when switching fabric colors.

Baldwin’s texcoat G4 precision spray system produces ideal results in fabric finishing, because the exact required amount of water and chemistry is always applied.

Baldwin’s texcoat G4 precision spray system produces ideal results in fabric finishing, because the exact required amount of water and chemistry is always applied.

“Our customers are major manufacturers in fabric dying, finishing and remoistening, and we want to provide outstanding service and support—even in times like this,” said Rick Stanford, Business Development Leader at Baldwin and the commercial leader of the US installations. “Not only does our precision spray technology enhance productivity in their process, but there is also zero waste, which goes hand-in-hand with the increased sustainability focus in the textile industry.”

“Our customers are major manufacturers in fabric dying, finishing and remoistening, and we want to provide outstanding service and support—even in times like this,” said Rick Stanford, Business Development Leader at Baldwin and the commercial leader of the US installations. “Not only does our precision spray technology enhance productivity in their process, but there is also zero waste, which goes hand-in-hand with the increased sustainability focus in the textile industry.”

In North Carolina, two new TexCoat G4 precision spray systems are now in production with major international vertical manufacturers of outdoor living, performance fabrics and automotive fabrics. In Georgia, a major vertical manufacturer of workwear and protective fabrics installed a sanfor precision spray system, which has helped the customer obtain deeper penetration of moisture into fabrics treated with durable water repellents. In Turkey, three new TexCoat G4 systems were installed in Çorlu, northwest of Istanbul, for a large producer of knit fabrics, such as T-shirts.

“In Turkey, the manufacturer purchased and installed one TexCoat G4 system before COVID-19, and the customer was so pleased with the results that, during the pandemic, three more were purchased,” said Simone Morellini, Sales Manager-EMEAR at Baldwin and the commercial leader of the Turkish installations. “The systems were manufactured and installed during the lockdown, and now, all four systems are up and running, and being used heavily on a daily basis.”

“In Turkey, the manufacturer purchased and installed one TexCoat G4 system before COVID-19, and the customer was so pleased with the results that, during the pandemic, three more were purchased,” said Simone Morellini, Sales Manager-EMEAR at Baldwin and the commercial leader of the Turkish installations. “The systems were manufactured and installed during the lockdown, and now, all four systems are up and running, and being used heavily on a daily basis.”

“With the success we have seen, we plan to apply the same strategies for upcoming installations, including the next one in Honduras: strong local management and customer coordination, combined with effective remote support during the installation,” said Stanford.

Baldwin TexCoat™ G4 – game-changing textile finishing spray technology: Baldwin’s precision spray systems for finishing and remoistening utilize non-contact spray technology, meaning that you will always have a controlled optimal coverage of the exact amount of liquids for reaching specific characteristics of the fabric.