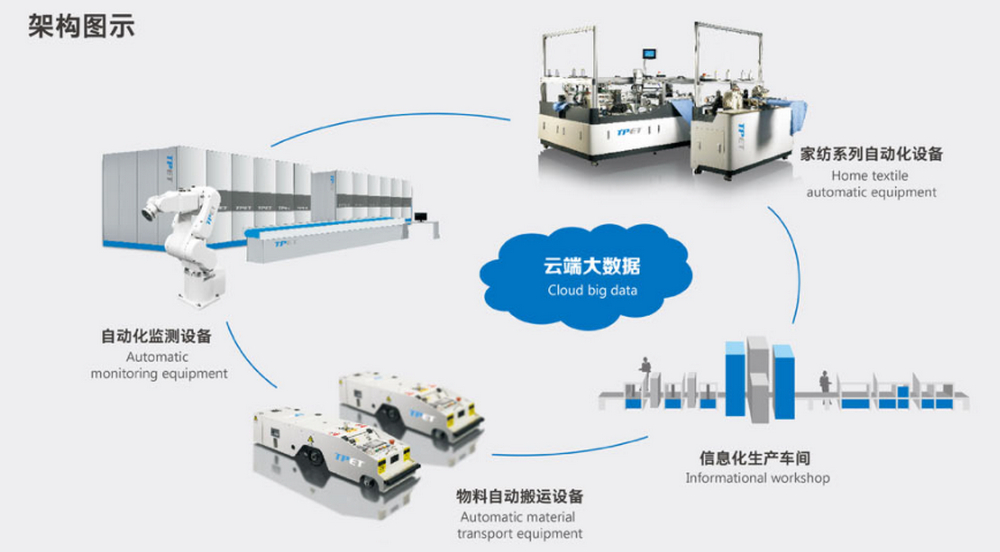

Intelligent Factory Platform

Research on Intelligent Manufacturing Transformation and Upgrading of Small and Medium-sized Garment Enterprises

Country: China

Abstract:

Intelligent manufacturing is not only the inevitable trend of manufacturing transformation and upgrading, but also the core of a new round of scientific and technological revolution and industrial revolution. Currently, the intelligent transformation and upgrading of China’s garment manufacturing industry are facing the dilemma of insufficient market, incomplete industrial chain, and immature system. This paper introduces the basic characteristics and development of intelligent manufacturing in garment industry, and summarizes a set of transformation and upgrading schemes of intelligent manufacturing for small and medium-sized garment enterprises based on the case of intelligent transformation of S company and the comparison of the actual situation before and after the transformation.

|