Coats, the world’s leading industrial thread company has launched Coats Armoren™, a range of cut protect yarns engineered for both protection and comfort in gloves and which offers game-changing solutions to the hand safety industry.

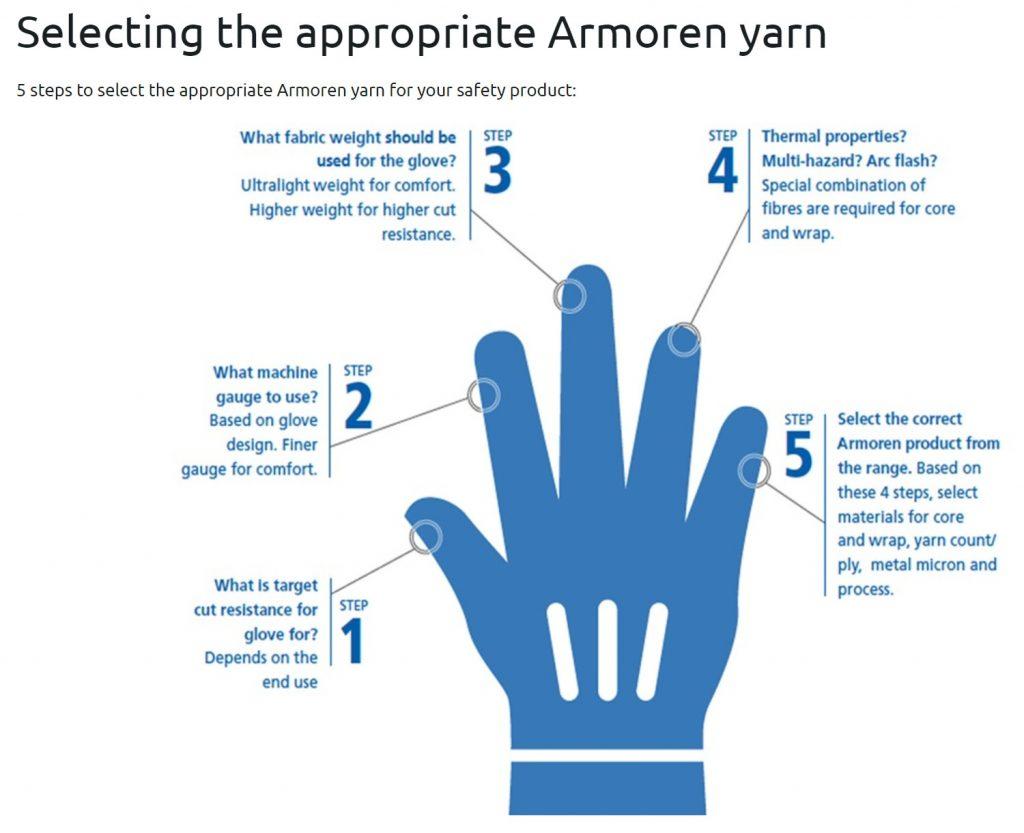

Coats Armoren uses a pioneering engineered yarn technology developed by Coats that incorporates cutting edge innovation for hand safety. New generation stretch fibres and high quality core yarn coverage create laser-fine gloves that are comfortable and have ultimate tactile dexterity. The proprietary helical core construction provides the power of extreme cut resistance; multi-risk and arc flash protection; and high contact heat resistance – even at fine knitting gauges. Armoren Ultracut has proprietary reinforced core constructions to meet extreme laceration hazards. Armoren Ultralight has extra-soft fibres engineered which provide yarns for laser-fine knitted gloves that offer ultimate dexterity and protection.

Coats Armoren uses a pioneering engineered yarn technology developed by Coats that incorporates cutting edge innovation for hand safety. New generation stretch fibres and high quality core yarn coverage create laser-fine gloves that are comfortable and have ultimate tactile dexterity. The proprietary helical core construction provides the power of extreme cut resistance; multi-risk and arc flash protection; and high contact heat resistance – even at fine knitting gauges. Armoren Ultracut has proprietary reinforced core constructions to meet extreme laceration hazards. Armoren Ultralight has extra-soft fibres engineered which provide yarns for laser-fine knitted gloves that offer ultimate dexterity and protection.

Ronan Cox, President, Performance Materials, Coats, said: ‘We recognise cut protection products must be as comfortable as they are effective. Coats Armoren responds to the evolving industry demand to meet high safety standards across a wide range of hazardous environments while also offering comfort and performance. We have developed an innovative range of solutions that ensure we continue to meet our customers’ needs.’

Also being brought under the Coats Armoren range are two existing products. Armoren X13 incorporates the latest fibre and spinning technology to provide superior cut resistance and high durability. Armoren X14 has a special fibre blend with cooling technology that wicks moisture and reduces body heat.

Also being brought under the Coats Armoren range are two existing products. Armoren X13 incorporates the latest fibre and spinning technology to provide superior cut resistance and high durability. Armoren X14 has a special fibre blend with cooling technology that wicks moisture and reduces body heat.

Coats has a pioneering record in engineered yarn technology. Its unique combination of innovative technology and technical expertise has been further consolidated through acquisitions. By bringing together the combined expertise and heritage of the Coats, Patrick Yarns and Pharr HP brands, Coats has developed the Coats Armoren range of products.

Game-changing solutions for hand safety Coats Armoren uses a pioneering J Spun engineered yarn technology that extends the frontiers of safety awareness in cut protection. New generation stretch fibres and high quality of core yarn coverage creates laser-fine gloves that are comfortable, and have ultimate tactile dexterity. The best in class, proprietary helical J Spun core construction provides the power of extreme cut resistance even at fine knitting gauges. The Coats Armoren product range of cut protect yarns is engineered for Ultralight comfort and Ultracut protection in gloves, and offers game-changing solutions to the hand safety industry. Coats Armoren can also be designed to protect against multi-risk hazards like electric arc flash, extreme contact heat, microbial infection, molten splash, chemical exposure, clean room electrostatic, and other dangers. It is brought to you by Coats, which is a global company with the engineering expertise and the innovation capability to meet increasingly stringent industry trends of safety and sustainability.

About Coats Coats is the world’s leading industrial thread company. At home in some 50 countries, Coats has a workforce of 17,000 people across six continents. Revenues in 2019 were US$1.4bn. Coats’ pioneering history and innovative culture ensure the company leads the way around the world. It provides complementary and value added products, services and software solutions to the apparel and footwear industries. It applies innovative techniques to develop high technology Performance Materials threads, yarns and fabrics in areas such as Transportation, Telecommunications and Energy, and Personal Protection. Headquartered in the UK, Coats is a FTSE 250 company, a constituent of the FTSE4Good Index Series and a participant in the UN Global Compact. It is also the Official Thread Supplier to the Royal Shakespeare Company.

- Each year Coats makes enough thread to go into 8 billion pairs of jeans – that is one for every person on the planet

- Every month Coats produces enough thread to stretch all the way to the sun

More than 450 million pairs of shoes are made every year using Coats’ thread

More than 100 million car airbags are made using Coats’ Performance Materials thread every year - In 1879 Thomas Edison used Coats’ thread in his experiments to invent the light bulb

Coats’ flame retardant Performance Materials threads can withstand temperatures as high as 1,000 degrees Celsius - Coats Epic Ecoverde is the world’s first 100% recycled premium sewing thread

Technical Bulletin Of Coats Armoren

To find out more about Coats visit: www.coats.com