Knitting, Weaving, Felting, Tufting, Carding and Sewing.

Knitting, Weaving, Felting, Tufting, Carding and Sewing.

Groz-Beckert is the world’s leading provider of industrial machine needles, precision parts and fine tools, as well as systems and services for the production and joining of textile fabrics. All around the world, the products and services support the textile processes of knitting and warp knitting, weaving, felting, tufting, carding and sewing.

The company, founded in 1852, employs around 9,000 people and turned over about 618 million euro in 2020.

Everything comes together at the headquarters in Albstadt, Germany. The family-owned company also has further production sites in Germany, Belgium, the Czech Republic, Portugal, the USA, India, China, and Vietnam. Numerous sales affiliates and sales partners complement the international presence.

Machine manufacturers and end users the world over place their trust in Groz-Beckert as a development partner and quality supplier.

Groz-Beckert offers its customers a comprehensive partnership – without boundaries and on site in over 150 countries.

The Product Sectors:

Knitting: Circular knitting; Flat knitting; Legwear; Warp knitting

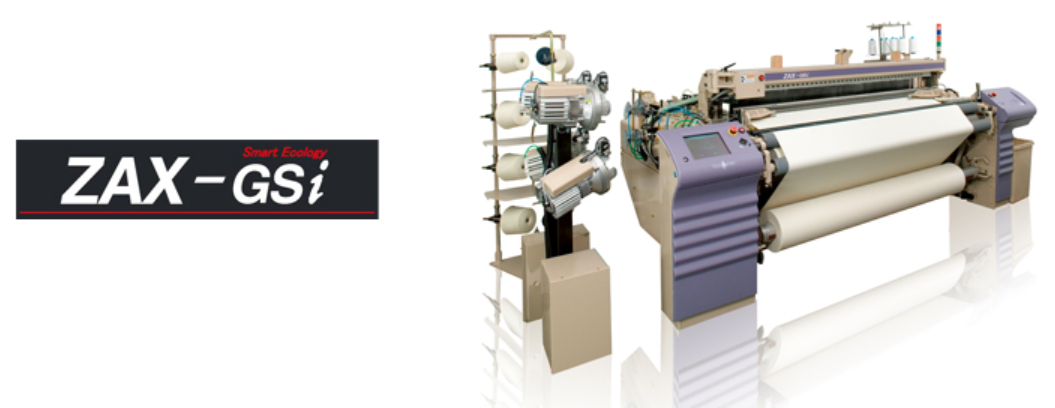

Weaving: Groz-Beckert products in use

The manufacture of woven textiles is known as the weaving process. A wide variety of components come into play here.

Before the weaving process can begin, the warp threads must be pulled through the drop wires, healds and reeds. Groz-Beckert supplies the appropriate machines (Drawing-in) for this step in the weaving process.

The actual weaving starts in the next step. Groz-Beckert’s warp stop motion system constantly monitors the warp thread.

The combination of Groz-Beckert heald frames and healds forms one of the most important components in the weaving process. One warp thread runs through the thread eye of each heald. If a heald frame moves, the healds aligned in it move, thereby also moving the warp threads. The raising and lowering of the heald frames results in an open shed into which the weft thread is inserted.

The last component in the weaving process is the reed, which pushes the weft yarn into place while maintaining alignment of the warp yarns. This brings the yarn intersections together into a fabric.

Areas Of Operation

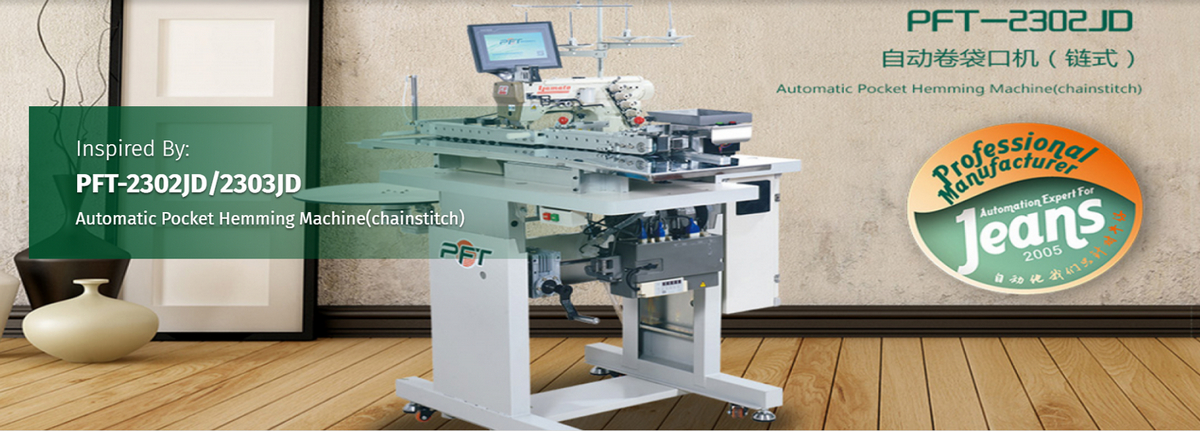

Fabrics for clothing textiles: Clothing is by far the largest market for woven fabric. Shirts, pants, shoes, protective and clean-room clothing are just a few examples of woven textiles with different features.

Fabrics for home textiles: Many home textiles such as curtains, carpets and upholstery are constructed with very different types of weaves. Special jacquard technology is often used here for patterning.

Woven fabric for technical textiles: Woven fabrics for the automotive industry, textile construction, facades, interior decoration and logistics are finding more applications. Such high-tech fabric is subject to specific requirements for high tensile strength and elongation.

Whether heald frames, healds, drop wires, warp stop motions, and products for leno weaving in the area of weaving accessories or knotting machines and frames, cleaning and drawing-in machines for weaving preparation: Discover Groz-Beckert’s comprehensive offerings for weaving on these pages.

Whether upholstery, headrests, door panels or roof liner – knitted fabric is ubiquitous in automobiles, although not necessarily visible at first glance. Knitted fabrics play an important role in the automobile industry. Especially in car interiors, there are amazingly many knitted constituent parts.

High requirements are made for the products. Safety standards are high, and design and functionality of extreme importance. Especially in vehicle interiors, textiles are exposed to solar radiation and high temperatures. Knitted fabric must withstand these stresses for many years.

Lastly, the higher elasticity and tensile strength of knitted textiles make them the go-to choice. Because of the higher elasticity the knitted fabric is more suited to draping and can be used anywhere.

In addition to textiles made of knitted yarns, knitted fabric made of other materials, such as metal, are also used. They can be found in radiator hoses, airbags and vibration absorbers.

Groz-Beckert Asia Private Limited

2nd floor, Vatika Professional Point

Sector-66, Golf Course Ext. Road

122002 Gurgaon, India

Phone: +91 124 4721800

E-mail: contact_gba@groz-beckert.com

Buying Houses

Buying Houses Madrid Shopping Center Spain

Madrid Shopping Center Spain Textile Chemicals and Auxiliaries

Textile Chemicals and Auxiliaries Textile Suppliers to Leather Industry

Textile Suppliers to Leather Industry

Knitting, Weaving, Felting, Tufting, Carding and Sewing.

Knitting, Weaving, Felting, Tufting, Carding and Sewing.