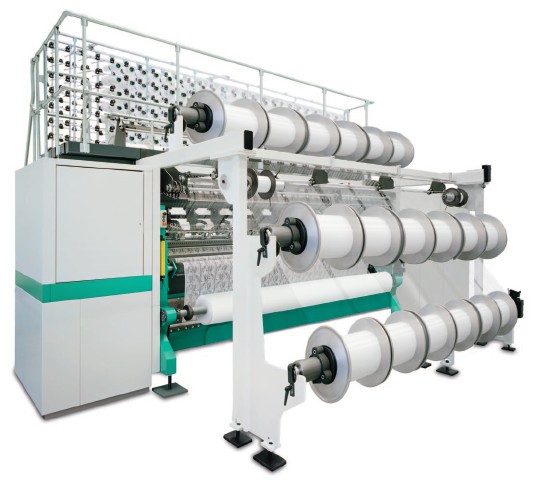

With the development of a new series of Multibar Lace machines KARL MAYER sets again standards in terms of productivity and quality, both concerning the machine and the lace articles produced on these machines. Based on the successful concept of the EL machine generation and on the well-tried string bar system, KARL MAYER has developed the machine series consisting of the types ML 34, ML41 and ML 46 intended for the Multibar lace market.

Due to a perfect synchronization of the existing knitting elements, it is possible to achieve the maximum performance when operating this new machine series. Having greatest possible flexibility and excellent operator convenience, the new machines offer the manufacturers of lace articles the possibility to comply with the different market requirements within a short period of time. Similar to all the models of the latest series, the new machines are also equipped with the tried-andtested pattern bar concept with strings, allowing a maximum shog path of 180 mm.

Another advantage is the considerably wider range of patterns that can be worked, compared to similar Multibar lace machines of the old generation. Thus, the manufacturers of all kinds of lace articles of different widths can make use of a high degree of design freedom when producing their textiles.

The technical equipment of this machine series is also state-of-theart, being characterized by simple operation and precise control of all the elements. Pattern guide bars driven by servomotors along with high operating reliability and low maintenance, are trend-setting for the drive concept employed. Working with the new generation of Multibar machines is made easier by another two features: the electronic fabric take-up and the batching device.

The modern control panel with Touch screen offers easy access to all important machine data and considerably facilitates the machine operation. Some of the advantages of the newly developed series of electronically controlled Multibar lace machines are: outstanding productivity, top flexibility and the usual first-class quality standard. Highest precision and long service life of all the machine components ensure a reliable machine operation, together with reduced maintenance over long periods of time.

Equipped with 30 string bars on the ML 34 or 42 string bars on the ML 46, both types are the ideal machines for the production of narrow or medium-sized elastic lace ribbons and all-over lace fabrics for the outerwear sector. Both machines have two stitch-forming ground guide bars. The machine type ML 41 with 36 string bars offer a wider range of fabric ground structures, due to their equipment with three stitch-forming ground guide bars. All the machines of this series are provided for the use of multiple guide fingers, thus, giving the lace article an additional sophisticated appearance and premium quality especially by means of greatly varying ground structures.

Key Features :

- High-speed & highly flexible lace m/c of the latest generation.

- Replacement of existing Multibar type series EH and SU.

- Equipped with the proven string bar system & EL technology.

- Short set-up times and easy handling.

- High operating reliability and low maintenance.

- Positive Patternbeam Drives available.

Contact details :

A.T.E. Enterprises Private Limited

A-19, CTS No. 689

Veera Desai Rd. Andheri (West), Mumbai-400 053 / India

Phone : + 91 /22/66 76 61 00

Phone : + 91 /22/66 76 61 17 (Mr. Shewale)

Fax: + 91 /22/26 73 24 46 Email : teg@ateindia.com