CEO Massimo Biancalani (left) and R&D Manager Maurizio Toccafondi

Biancalani has many professionals who have the ability to see the whole before joining a puzzle’s piece. These professionals can see a whole by reviewing all the pieces individually. They support it by targeting innovation and progress in the industry with their basic ideas. Biancalani, which has been part of the textile machinery industry for many years with employees with this vision, continues to steer this sector.

Company CEO Massimo Biancalani is what is missing and desired in textile machines? He states that they continue their innovations and innovations by accepting the basic principle. With this thought structure, Biancalani’s ability to react quickly to the continuity and needs of the industry is high.

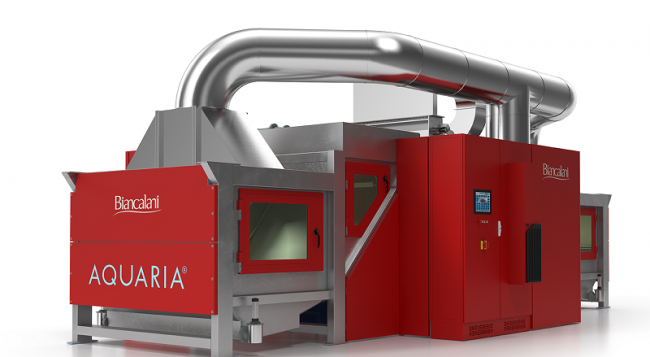

R&D Department Manager Maurizio Taccofondi states that the design and technology of Biancalani’s open most washing machine Aquaria is formed and developed in this way. While looking for a different vision based on tradition and experience but not ordinary, Biancalani focused on six powerful features in a single machine with this R&D and innovative structure, and this state-of-the-art alternative machine presented it to the textile industry. This offers exceptional results, some built-in and some to discover.

Massimo Biancalani speaks like this. “Research before design may seem energetic, but in reality the correct terminal is the most important. The opinions of mümessilliks and professionals in the industry, market analysis, statistics and research on the internet are organized by the R&D department. It is the impulses that result from these researches that trigger the design. Biancalani employees are also gathering under the roof of the company because they are open to these thoughts and innovations.”

The director of the R&D department is willing to set a concept:

“Design cannot and should not risk future technology by creating weak machines. This usually happens, as we said, only when trying to reduce the machine to the bone to provide a product that is apparently new but actually devoid of content. It is a mistake. Technological content prevents everything. All relevant R&D sectors operate on the basis of this obligation.”

Massimo Biancalani, the creator of his designs, technically understands ourselves is a synthesis of creativity and guides his designs. Biancalani; It benefits from the synthesis that occurs by bringing together many different professionals in terms of experience, age and expertise in the name of innovation. Airo®24 is this synthesis that guides Airobox and Aquaria® machine designs.

Toccafondi continues: “When you have a full view of the project and after the machine’s construction, there is another interesting step: Biancalani is often the only supplier and clearly supportive of his own design philosophy, as well as being a consultant. The company turns into a strategic partner as it provides all this. The highest level common to the design and construction stages is reached when leading customers in the textile finishing industry choose to test an innovative machine.”

“At this point, Biancalani comes into play. Toccafondi; “We offer our technology experts working daily to adjust the machines to the needs of the customer and discover the perfect functionality for what he wants to achieve. This is the real connection with innovation, because leaders in the industry open the way forward, which moves the market forward and others follow it.says.

Biancalani machines are personalized according to the customer’s needs. As understood from Maurizio Taccofandi’s saying “I don’t remember making one machine the same as the other,” it has a production potential with superior technology and equipment that can design every request of its customers on the machine. Stating that every machine produced and personalized has a separate potential, Biancalani professionals state that they always encounter the needs and innovations they discover differently during these productions. Power and versatile production is the secret of Biancalani textile finishing machines.”