Groz-Beckert needles play a key role in manufacturing textiles

Groz-Beckert, a family-owned business since its inception in 1852, stands as a cornerstone of the global textile industry. Their comprehensive range encompasses industrial machine needles, precision parts, fine tools, and extends to encompass systems and services crucial for textile production and joining. Their influence spans a wide spectrum of textile processes, including knitting, weaving, nonwovens, tufting, sewing, and spinning. The company’s overarching mission centers on providing unparalleled value to its customers. This is achieved through a synergistic approach combining superior products, comprehensive services, and tailored solutions meticulously designed to optimize production processes. Central to their philosophy is the cultivation of robust partnerships with customers. This collaborative approach fosters open communication, fuels joint innovation, and establishes strategic cooperation, ultimately benefiting all stakeholders. Exemplifying this commitment are recent successful collaborations such as the INNOTAS knitting system developed in partnership with Santoni, an innovative compound needle for circular knitting machines created with Vanguard Pailung, and a cutting-edge felting needle module co-developed with the Dilo Group for their groundbreaking MicroPunch intensive needling technology.

Navigating Global Economic Headwinds and Industry Transformations

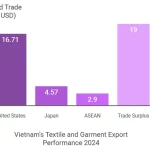

The prevailing global economic climate, characterized by a slowdown and significant structural changes in textile markets, has presented considerable challenges. Geopolitical conflicts and trade disputes have cast a long shadow of uncertainty, dampening investment and consumer spending. These headwinds have had a palpable impact on Groz-Beckert’s Textile Tools business unit. While a modest recovery in demand is projected for 2025, China presents a unique scenario. The country’s deflationary environment has resulted in exceptionally low prices, further exacerbated by the ascendancy of ultra-fast fashion platforms that directly reach global consumers. This has placed additional strain on traditional clothing manufacturers, particularly in Southeast Asia.

Pioneering R&D for a Sustainable Future

Groz-Beckert’s research and development (R&D) activities are strategically oriented towards addressing the fundamental shifts occurring within the textile industry. Their focus is on anticipating long-term trends and developing innovative products, services, and business models that precisely align with evolving customer needs. Sustainability is not merely a buzzword but a core principle deeply embedded within their operations. Looking ahead, Groz-Beckert recognizes the imperative to develop novel business models that cater to an increasingly complex, individualized, and fast-paced world. This includes exploring concepts like pay-per-use models, recognizing that such solutions may not be universally applicable but hold significant potential for specific customer segments. To ensure relevance and effectiveness, Groz-Beckert maintains close collaboration with customers, particularly in the realm of R&D.

The Critical Role of Textile Tools in Quality and Productivity

Textile tools exert a direct and substantial influence on both the quality of the final product and overall productivity across all textile manufacturing processes. The selection of appropriate tools is paramount for achieving uniform stitches, flawless surfaces, and optimal machine speeds. Conversely, using incorrect tools can lead to yarn damage, compromising fabric quality and longevity. The choice of tools also affects the usable machine speed and needle durability. Recognizing the complexities of needle selection, Groz-Beckert offers the “Needle Finder,” an interactive tool designed to simplify this process. The Needle Finder showcases various product examples with different seams, providing detailed application information, including stitch type, recommended needle point and size, and suggested needle systems. Complementing this, the Groz-Beckert Academy Mobile offers a wealth of knowledge through online seminars conducted in over 12 languages. These seminars cover a broad range of topics related to the textile industry and Groz-Beckert products, providing valuable insights and expertise to customers worldwide.

The Turkish Textile Industry: Navigating Challenges and Embracing Opportunities

The Turkish textile industry faced a turbulent year in 2024, grappling with global uncertainties, weakened export demand, escalating production costs, and unfavorable exchange rates. These factors combined to exert significant pressure on Turkish producers, impacting profit margins and global competitiveness. Existing overcapacity from prior investments and high interest rates further complicated investment plans. However, a more optimistic outlook is anticipated for 2025, with projected improvements in exchange rates, interest rates, inflation, and export market demand. Türkiye’s strategic geographical proximity to Europe, coupled with its short supply times, access to high-tech machinery, and a skilled workforce, positions it as a vital player in the textile landscape. Even with potential shifts in production to lower-cost countries, Türkiye is expected to maintain its importance as a central hub for management, purchasing, and logistics.

Innovation in Staple Fiber Knitting: The SAN™ SF Needle and SNK SF Sinker

Groz-Beckert’s commitment to innovation extends to specialized system parts. The SAN™ SF special application needle and the SNK SF sinker are prime examples, specifically engineered to address the unique challenges associated with knitting staple fibers. These components effectively mitigate lint accumulation, leading to extended cleaning cycles, enhanced productivity, and reduced production costs. The SAN™ SF needle’s distinctive shank geometry prevents residue buildup, while the SNK SF sinker minimizes lint in the verge ring. Field tests have demonstrated the efficacy of this combination, keeping needle tricks clean three times longer than conventional solutions. This innovation underscores Groz-Beckert’s dedication to providing cutting-edge solutions that optimize efficiency and performance in textile production.