On March 7, 2020, Bangladesh searched for the first confirmed case of Covid-19 and it carried out this operation with complete lockdown from March 23, 2020.

Many garment factories were closed in this situation and most of the workers could not go to their homes as the lockdown continued. Some factory owners have stopped paying their workers. Almost $2.25bn RMG export orders were canceled and suspended till 24 March 2020. The total supply chain in the textile and RMG sectors has been broken. Workplaces and employees have suffered the most due to job losses.

Job loses

The a2i study revealed that about 0.5 million workers in the textile and RMG sectors are permanently unemployed and many more are on the verge of being laid off due to the ongoing crisis. Also, the interconnected employment with this industry is detrimental. 4 million truck drivers, port workers, and suppliers are at risk of losing their jobs in the workers and textile sectors. But some of the factories had probably laid off thousands of workers permanently due to declining and declining order of clothing. Many small factories have already been evicted.

| Employment situation during the lockdown in Bangladesh RMG and textile sector | |

| 67 factories, including seven non-RMG units, laid off a total of 17,579 workers in March. | RMG workers received 65 percent of their monthly wages in April |

| 8% of garment workers were unemployed in September. | About 0.5 million workers in the textile and RMG sectors are permanently unemployed. |

According to official data from the industrial police, at least 22,400 RMG workers were laid off by July, and about 20,000 RMG workers lost their jobs, according to the labor ministry. Labor leaders, however, claim that this number is much higher than what official data shows.

The Bangladesh Garment Manufacturers and Exporters Association (BGMEA) claimed that about 376 factories were closed during the epidemic, affecting both entrepreneurs and workers. RMG workers received 65 percent of their monthly wages in April, and many small and medium-sized enterprises that worked as large factory and factory subcontractors that announced layoffs were unable to qualify for funding due to conditions and, as a result, could not pay their workers.

According to the Department of Factory and Establishment Inspection (DIFE), about 67 factories, including seven non-RMG (readymade garment) units, have laid off a total of 17,579 workers in March. Also, data from the Industrial Police (IP) shows that 10,493 workers lost their jobs in five industrial zones except for the Dhaka metro area during the outbreak.

26 factories located in Dhaka terminated 7,488 workers and 30 Gazipur units 9,193. An estimated 554 workers from 2 factories in Narsingdi, 193 from six units located in Narayanganj, and 151 from 3 units in Chattogram were terminated.

Current employment job situation

BGMEA President, Dr. Ruabana Huq said factories are now operating at 55 percent production capacity due to lack of work orders and maintaining health safety guidelines, maintaining social distance, and working with less manpower.

However, the government has taken swift action by announcing stimulus packages for export-oriented industries. The total amount of this package is 5000 crores. The money allocated from the package can be disbursed only in the form of salaries and wages to the employees and workers of export-oriented industries including the garment industry. The required amount can be taken from the package at 2 percent interest. However, the RMG sector has finally overcome this situation and now most of the factories are operating on a full scale.

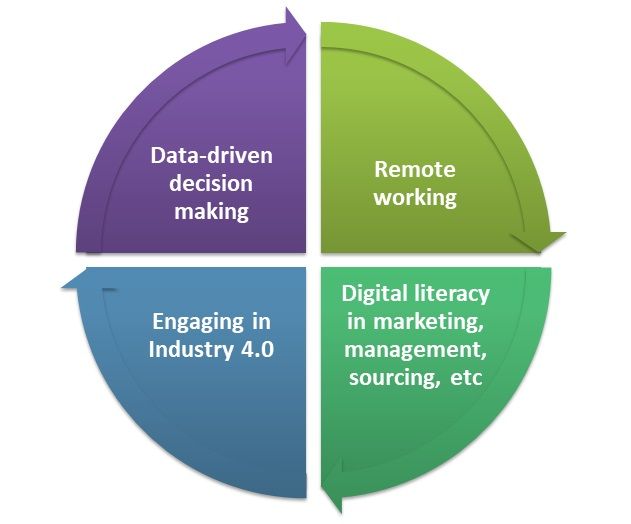

In November, Bangladesh’s textile and RMG sector receipts up to $3.1b exports. However, with this success, the unemployment of the workers is not decreasing. On the other hand, a large number of graduates will soon enter the industry where they will have to face new challenges in the industry. Where they will see that conventional marketing has changed to digital marketing, physical product exhibitions transform into virtual product exhibitions and starting with automation. This will create a huge skill gap between industrial and academic knowledge.

Syed Mahmudul Huq, President and Event Moderator of CCIFB, said that the COVID-19 epidemic has put a lot of pressure on individuals, enterprises, and society and forced them to accelerate the use of various 4IR tools.

BGMEA President, Rubana Huq spoke about how the expected transformation into automation and the cyber-enabled system would have a tremendous economic impact on the nation and the RMG industries in the short term.

Initiatives

The epidemic has taken away employment in the RMG and textile sectors. The government of Bangladesh took the first initiative with a stimulus package of TK 5,000 cores for salaries and wages of employees and workers. The distribution of salaries to garment workers from the stimulus package started from May 3.

The government has taken the best initiatives to save employment in the RMG and textile sectors. Now is the time for large organizations to create more skilled manpower. Industries are moving forward and looking for more innovative strategies. Soon fresh graduates and conventional workers will face changes in this industry. Rubana Huq, said, “25% of garment manufacturing activities in Bangladesh will be automated by 2023, up from 8 percent are already engaged.”

Without proper skills, it will be difficult to survive in the RMG and textile jobs sector in the future. Ahsan H Mansur, executive director of the Policy Research Institute of Bangladesh said, “Riding on incompetent manpower we cannot go in abundance.”

ADB is assisting the government in creating manpower in the RMG industry. As of March 2020, ADB has supported the training of 62,834 workers in the sector under the Skills of Employment Investment Program.

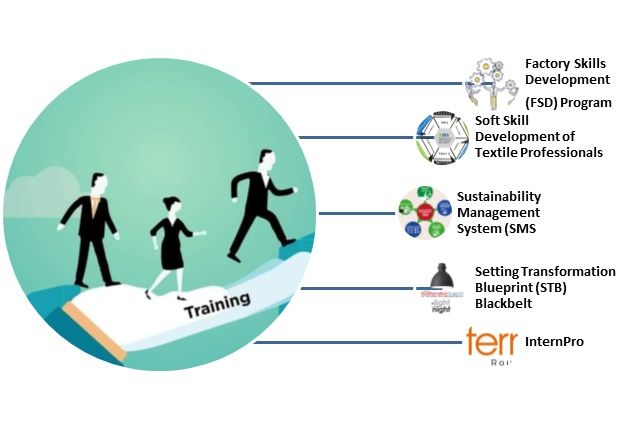

To alleviate this dire situation, Textile Today Training (TTT) also has taken initiatives to transform professionals into skilled human capital through various comprehensive training programs. Textile Today is serving as a platform to consolidate resources for training professionals in the industry and those who want to join the training.

Textile Today has teamed up with factories like Northern Toshirifa Group, APS Group, RASS Biotech and is providing certification on yellow, green, and black belts in terms of core technical expertise. TTT is also providing training in soft skills development and building professionals for sustainable management in the industry.

(Courtesy: Textile Today)