Industry 4.0 includes cyber-physical systems, the Internet of things, cloud and cognitive computing. (Source: Wikipedia) Image Credit: Christoph Roser

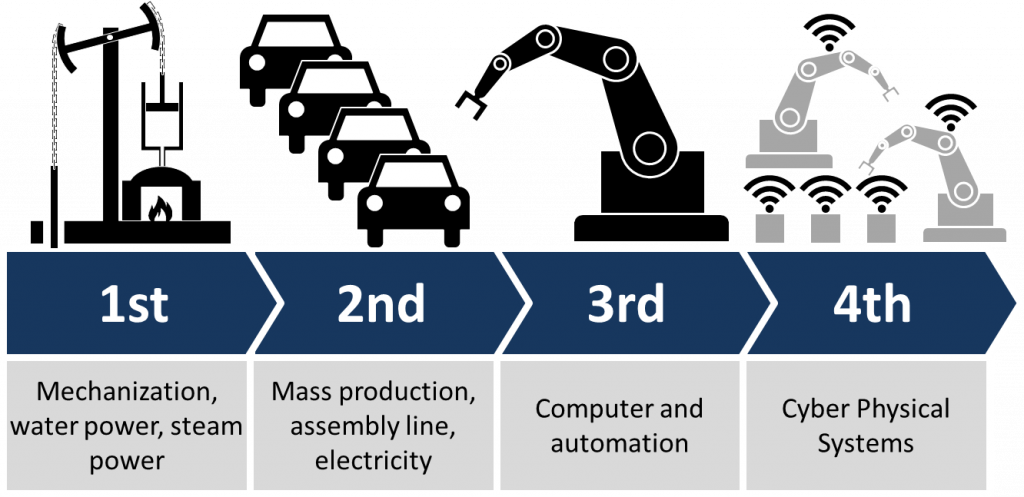

“Industry 4.0” is the new buzzword becoming very fashionable, and hence, considerably over used. The credit for coining this iconic word goes to Siemens at the Hanover Messe in 2015. Industry 4.0 – also termed as the 4th generation of the industrial revolution – marks the beginning of a new era. It essentially represents the digital transformation of traditional industries like manufacturing to intelligent factories with the advancements in automation, advanced materials, 3D printing, artificial intelligence, augmented reality, cobots (collaborative and robots). Adaptive and ergonomic production lines, intelligent robots and integrated energy systems – all parts of Industrial Internet of Things (IIoT) – are increasingly making it possible for companies, in practically every industrial and manufacturing sector, to digitize their operations. This digital transformation is enabling them to become 24×7 connected intelligent factories. The computerization of traditional industries, like manufacturing, i.e. their transition to intelligent factories, is going to be the key to their survival in a couple of years from now.

In a nutshell, Industry 4.0 converts your facility into a smart factory by providing it a working brain to impart more advanced built-in intelligence for the factory equipment and products enabling them to work together. Hence, the product will be able to tell the machine – at components level – what to do. The factory equipment runs on very sophisticated software which helps machines self-regulate and make more autonomous and intelligent decisions.

The key features of a “smart’ or “Digital” factory are: self-optimization, self-configuration, self-diagnosis, cognitive and machine learning to significantly increase the efficiency and output while reducing the waste and unnecessary tasks with minimum human intervention. However, there are already alarm bells ringing that the Industry 4.0 will lead to huge displacement of workforce as tiny intelligent robots can replace them for doing the same job more accurately, rapidly and economically.

In a comment, made in Sept. 2011, in support of his ambitious project Steve Dickerson said: “My fundamental comment is that this program should strive to make manufacturing in the US competitive as measured by the effect on balance of trade. One simply needs to look at importation of goods and the corresponding industries to see where emphasis might be placed. I think we are running in the 3 to 4% of GDP as an imbalance of trade. Two industries that are dominated by imports are garments and related sewn items; and assembled electronics such as cell phones, computers, TVs etc. Both imbalances should be possible to largely eliminate. Garments represents about $100 billion per year.” He further added: “It turns out that Georgia Tech and SoftWear Automation think that they know how to make garment manufacture competitive with low wage countries. But a good deal of R&D needed. By the way, it does turn out that fully automated sewing has been considered “impossible” but is not. A fundamental innovation has been made and preliminary research funded by both the State of GA and the Navy shows it probably is feasible to fully automate garment manufacture.”

Steve Dickerson of SoftWear Automation delivers a TEDx talk on Automated Robotic Sewing in the Bay Area. October 23, 2012.

A recent case in point is “Sewbot” – a robotic sewing system – from Atlanta-based company SoftWear Automation. The Georgia Tech spinoff SoftWear Automation, Inc. was founded by Dr. Steve Dickerson, who observed that the apparel industry had almost entirely disappeared from the US, including in his family’s home town of Commerce GA. Dickerson – inspired by the automation solutions offered by Japanese industry – initiated efforts to achieve similar automation for the sewing operations involved in garmenting. Softwear was established to develop completely automated production facilities for garments without any direct labor.

The system can cut and sew the soft fabric automatically. The machines use a combination of cameras and needles to track the placement of a fabric before sewing the apparel. Softwear claims their system offers more accuracy than the human eye. In fact, a Chinese firm (Tianyuan Garments Company of Suzhou) is setting up a factory in the US (in Little Rock, Arkansas) with 21 Sewbot production lines for producing 800,000 T-shirts a day for Adidas. SoftWear’s fully automated Sewbot roughly takes four minutes from fabric cutting and sewing to finished product. The system is scheduled to be fully operational by the end of next year. With all the production lines in operation, with complete automation, Tianyuan Garments estimates to make one T-shirt every 22 seconds @ a labor cost of just 33 cents for each T-shirt. A cost so low that no country in the world can compete with.

https://www.youtube.com/watch?v=vAa7DSY65Qs

Introducing SoftWear Automation. Robotic sewing technology in action. This technology will bring fabric manufacturing back to America. SoftWear Automation lowers cost by improving productivity. It will make customization simple and affordable on a mass scale. Contact www.softwearautomation.com for more information. (Source: Softwear Automation)

At present, SoftWear Automation is taking pre-orders for fully automated worklines for t-shirts, and workcells for hemming & binding. Future products include: Jeans & pants, pillows, bath mats, automotive mats, mattresses, towels and tote bags. Tianyuan Garments Company’s facility in Arkansas (USA) will perhaps be the first true example of Industry 4.0 in the textile and clothing sector. So far, the sector was enjoying fruits of automation technology in every sphere except sewing. This is a classic example of how an Industry 4.0 ready technology can disrupt the $100 billion sewn products industry by creating autonomous sewn good worklines for apparel, home goods and footwear with additional benefits of higher quality and lower cost.

Germany has taken a leadership position in adapting ‘Industrie 4.0’ high-tech strategy that is based on almost fully computerizing the manufacturing industry without the need for human involvement. The German government is investing some Euro 200 million to encourage research across academia, business and government for what it calls “to deal quickly with the fusion of the online world and the world of industrial production.”

Also, an open, smart manufacturing platform for industrial-networked information applications to promote Industry 4.0 is being planned by the Smart Manufacturing Leadership Coalition (SMLC), a non-profit organization comprising of manufacturers, suppliers, technology firms, government agencies, universities and laboratories.

In the Indian context, it is difficult to visualize how the things might shape up with respect to Industry 4.0 which calls for more and more automation at each stage, and also more frequent than we are all accustomed to. There is a general reluctance from stakeholders and investors to spend heavily in new technologies. Also, the possibility of the resultant job losses, in labor-intensive sectors like textiles, needs to be carefully looked into. However, it may appeal to a number of big corporates, and also to entrepreneurs who prefer to work with limited labor, to explore the opportunities offered by Industry 4.0 — the symbol of flexibility, adaptability and efficiency. The key barriers include: data security issues, less human oversight, loss of human jobs, technical problems can cause expensive production outages.

Industry 4.0 is going to take over the manufacturing world sooner or later. It is also a fact that the early adopters may not be rewarded for their courage to embrace this new technology. But, at the same time, it wouldn’t be easy to imagine that those who totally avoid change don’t risk becoming irrelevant and left behind in the long run. Even if we assume that a lot of hype has been built up around Industry 4.0 over the past few years, there is no denying that in certain areas, including some very high-tech ones, it has demonstrated an unmatched advantage in terms of value addition and profitability. This is sufficient to motivate world’s leading players to take the technology to the next level, and on a wider horizon.