For half a century, Gerber Technology has been helping companies around the world develop, manufacture and take their products to market smarter, faster and more efficiently. Today, the company provides integrated software and hardware solutions to customers in the aerospace, construction, furniture, fashion & apparel, transportation, technical textiles, packaging, wind energy and sign & graphics industries, including over 100 Fortune 500 companies in 134 countries. Drawing on a rich history of innovation, Gerber Technology’s leading-edge systems help customers reach their optimum by maximizing productivity and minimizing errors and waste. Based in Connecticut, USA, Gerber Technology is owned by American Industrial Partners, a New York-based, global private equity firm with more than $3 billion in assets under management. World Headquarters: 24 Industrial Park Road West Tolland, CT 06084 USA

For half a century, Gerber Technology has been helping companies around the world develop, manufacture and take their products to market smarter, faster and more efficiently. Today, the company provides integrated software and hardware solutions to customers in the aerospace, construction, furniture, fashion & apparel, transportation, technical textiles, packaging, wind energy and sign & graphics industries, including over 100 Fortune 500 companies in 134 countries. Drawing on a rich history of innovation, Gerber Technology’s leading-edge systems help customers reach their optimum by maximizing productivity and minimizing errors and waste. Based in Connecticut, USA, Gerber Technology is owned by American Industrial Partners, a New York-based, global private equity firm with more than $3 billion in assets under management. World Headquarters: 24 Industrial Park Road West Tolland, CT 06084 USA

Helping to create Personal Protective Equipment (PPE) that saves lives

During these unprecedented times, it’s important for medical and safety professionals, and even consumers, to have the protective gear they need to remain healthy and safe. By leveraging Gerber Technology’s fully-connected Industry 4.0 solutions and their decades of expertise, you’ll be able to quickly, efficiently and sustainably produce the personal protective equipment (PPE) at the speed and quality you need.

A technology partner you can trust

Gerber Technology has been working with manufacturers to ensure effective, quality PPE is getting to the market at the right time. Through their PPE Task Force, Gerber has helped thousands of companies produce PPE for medical and consumer use by providing them with the knowledge, resources and technology necessary to make the transition to PPE production as smooth as possible. In addition, Gerber is helping to connect their global network of manufacturers and suppliers through the “PPE Manufacturing Matchmaking Program” to make collaboration simple.

“According to the World Health Organization (WHO), 89 million medical masks and 76 million examination gloves are required for the COVID-19 response each month. The WHO estimates PPE manufacturing needs to increase by 40% in order to keep up with demand.”

Efficient production, effective products

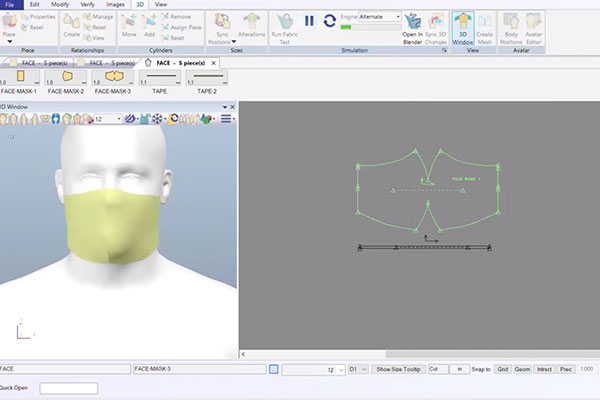

Gerber’s powerful end-to-end platform makes digital product development easier than ever before by seamlessly passing data throughout the supply chain, reducing costs, accelerating time to market, and improving the overall quality of the finished product. The connected solution helps you sustainably develop accurate patterns with AccuMark® 2D, validate them with seamless 2D-to-3D integration, all while leveraging YuniquePLM® to keep your data in one place for a truly optimized and efficient workflow. Gerber Technology offers a complete end-to-end textile manufacturing solution that allows you to go from design to production faster than ever before. Print digitally to keep up with consumer demands and offer greater design flexibility.

Gerber Personal Protective Equipment (PPE) Retooling Package: The tools and expertise you need for a successful transition to PPE production

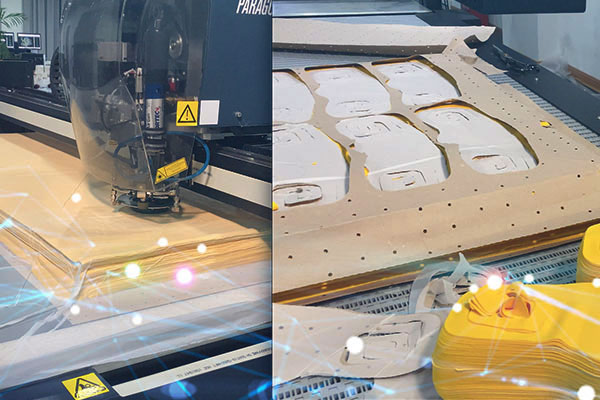

With the global shortage of personal protective equipment (PPE), transitioning production to produce PPE is a matter of saving lives and jobs. Technical Materials used for PPE are woven and non-woven, natural and poly blends, with some requiring several materials to be layered together to meet regulations and compliance. Due to the complexity of PPE, manufacturers must have the right software, hardware and expertise to quickly, efficiently, and sustainably manufacture PPE of the highest quality. In order to successfully transition to PPE production, manufacturers must have flexibility with the toolset, whether it be hardware or software, meaning companies may need to change the setup of their cutting solution in order to successfully produce PPE.

The Gerber PPE Retooling Package includes everything you need to produce PPE effectively and efficiently, at the right time. The package includes the Gerber Paragon® PPE Edition for the HX and LX as well as Gerber’s AccuMark® and YuniquePLM® to ensure your data stays connected and accurate for maximum uptime. All supported by Gerber’s expertise to ensure success. The PPE Retooling Package will allow manufacturers to produce up to 150,000 medical gowns and 6 million non-medical masks per week*.

*Based on 3 shifts, 6 days per week.

Everything you need for a smooth transition

With Gerber’s integrated end-to-end solutions, you’re able to efficiently produce hundreds of products at once to protect yourself, medical professionals, and your employees. The Gerber PPE Retooling Package is designed to make your transition to PPE production as seamless as possible. With a pre-packaged set of options for the Gerber Paragon® HX and LX, essential spare parts, additional software and consulting services and support add-ons, you’ll have everything you need to produce the highest quality PPE.

PPE made personal

As today’s consumers take their health and safety into their own hands with their own PPE, they’re counting on manufacturers to offer more than just plain, white masks. With Gerber’s on-demand workflow, you’re able to design and develop personalized masks that will allow your consumers to truly express who they are. The fully-integrated process quickly turns ideas into a reality by leveraging the latest in 2D/3D CAD, PLM, and nesting solutions as well as the most advanced digital printing and cutting technology, taking you from concept to finished product in a matter of hours. More details here.

Supporting you every step of the way

Whether you’re transitioning to PPE or looking to optimize your existing production, Gerber has the expertise to help you succeed. Gerber’s team of experts have successfully helped manufacturers all over the world optimize their PPE production by advising on regulations, sharing best practices, and providing dozens of helpful production-ready files and other resources to make the transition as efficient as possible. Get connected with the support team.

Downtime should never be an issue

With advanced Remote Support solutions, such as GERBERconnect™, a Field Service Technician can access your system from anywhere in the world. A Gerber Certified Technician is able to quickly diagnose, troubleshoot, install and solve any issues you may be having without ever having to set foot in your facility. Whether you’re having a technical issue or need a software update, Gerber’s Remote Support solutions are your best option for getting back up and running quickly. Get Remote Support.

Attend Gerber’s On-Demand Virtual Events: Stay agile with the comprehensive virtual event offerings from transitioning to personal protective equipment (PPE) production, to fashion on-demand prodution to mass production.

Gerber PPE – Go from Design to Production Seamlessly with Fully-Integrated Software

Gerber software bundles provide you with the solutions you need to stay competitive in today’s ”see now, buy now” world. Each bundle is designed to get you started quickly and easily with no upfront cost.