This report covers the specific areas of outdoors/sports textiles and medical textiles enhanced by nanotechnology. In the textile sector three main segments are distinguished : apparel (fashion), interior textiles and technical textiles. In Europe, the value distribution for the year 2008 was the following : apparel 37%, interior 33% and technical textiles 30%. In general, during recent decades the technical textiles segment has seen the strongest growth; for example during the period 1995-2005 the value of this market has grown from Euros 65 to Euros 85 billion. In terms of tonnage (not value) Europe is not the largest market for advanced technical textiles; Asia consumes 8.5 million tonnes, about half of global technical textile production, whereas US and Europe consume 5.8 million and 4.8 million tonnes respectively. In Europe four countries consume about half of the technical textiles in terms of value: Germany, France, the UK and Italy. The technical textiles industry in Germany is 45% of the textile industry, compared to 30% in France, 30% in the UK and 12% in Italy.

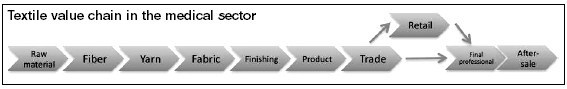

Non conventional advanced technical textiles, are high added value products and represent, at the moment, a limited portion of technical textiles sector. However, they are expected to grow steadily in the forthcoming future, progressively gaining a larger share in terms of both volume and value, in a large variety of sectors including medical textiles and sports/outdoors textiles. The sports/outdoors textiles business covers a quite stretched value chain all the way from fibre production (above all cotton but increasingly advanced polymer fibres) towards spinning of yarns, weaving and knitting of fabrics, subsequent design and production of finished garments and shoes, which are then transported to retailers who sell them to consumers. A relatively limited amount of advanced technology suppliers provide treatments (mainly coatings), some of them nano-enabled, which are applied either on the fibres, on the yarn or on the finished product. The value added in each step of the value chain increases from the early steps (fibres, yarns) towards the later steps (design, marketing, retailing). Main drivers in the sports/outdoor sectors are the increased need to offer recognizable functional advantages for high priced brands, in order to maintain their positioning compared to second tier retailerspecific low cost/mid price garments.

Definitions

The following definitions are as reported in the proposed ISO/DTS or ISO/DTR 12802, and ISO/DTS 11751, or as generally reported in the literature.

- Nanotechnology – The application of scientific knowledge to control and utilize matter at the nanoscale, where size related properties and phenomena can emerge.

- Nanoscale – Size range to approximately 1 nm to 100 nm.

- Nano-object or Nanostructure – Material with one, two or three external dimensions in the nanoscale

- Nanoparticle – Nano-object with all three external dimensions in the nanoscale.

- Nanofibre – Nano-object with two external dimensions in the nanoscale and the third dimension significantly larger.

- Nanotube – Hollow nanofibre

- Nanoporous – Structure with pore sizes in the nanoscale.

- Nanoclays – Layered silicates, as for example montmorillonite, in the nanoscale

- Nanocomposite – A composite of different materials or chemical substances in which at least one component includes a nanoparticle or other nanostructure

- Nano-textiles or Nanoengineered textiles – Textiles or textile products in which nanotechnology is used during a production or finishing step.

Concretely the textile industry directed at sports/outdoors markets and medical markets are currently seeking the following functionalities: Antibacterial (containing a biocide, or photoactive); Self-cleaning, Water/oleo repellence (photoactive, or super-hydrophobic, or antiadhesive); Moisture absorption; UV-blocking; Tear/wear resistance; Thermal insulation; Conductivity (for antistatic purposes mostly); and Controlled release of active chemical agents such as drugs, cosmetics, fragrances. It should be noted that for each of these functionalities non-nano alternative technologies also exist, which will compete with new nano-enabled developments. The most common applications are currently infection prevention or deodorisation of medical clothing, wound dressing, and bedding. Most other applications have still to reach mass markets; for example nanofibre filters. In sports and outdoors textiles, the main application presently found in the market is that of nanosilver used to reduce unpleasant smells in sport garments. Hydrophobic treatments are also gaining increasing interest from large global companies and can be expected to grow rapidly over the next couple of years. The application of nanotechnology enabled sensing devices in the combination of electronics and textiles enables the manufacturing of “smart” clothing with active functions, such as sensing, actuating and communicating functionalities. At prototype level, garments with integrated heating elements, devices that can stimulate muscles, or which are able to control/monitor athletes’ physiological parameters and their performance, have been produced. However, the industry still has a long way to go before nanotechnology enabled products become commonplace.

Overview

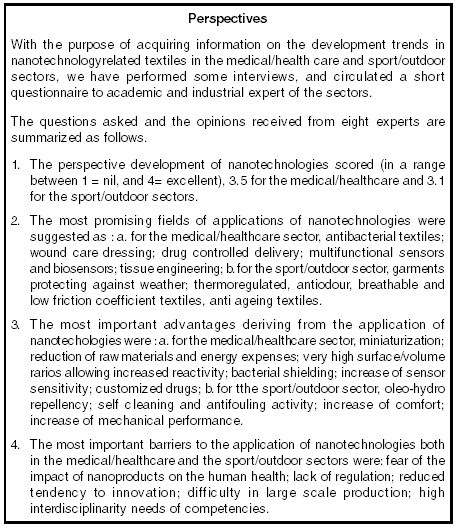

This new report, prepared under the European ObservatoryNANO project, is devoted to the analysis of two specific segments where such innovative technologies have a wider potential, namely, the medical/healthcare and sport/outdoor sectors.

Textiles products are usually classified according to their end market. Therefore we can talk of apparel (fashion), interior textiles, and technical textiles. In Europe, each of these segments account, roughly, for 1/3 of total market share (Apparel 37%, interior 33% & technical textiles 30%)

The technical textiles segment has experienced the largest increase in consumption during last years with high performances and non conventional technical textiles gaining ever growing attention. According to the European Commission (EC): ”expenditure on research and development (R&D) is higher in this field than for ‘conventional’ textiles reaching an investment of up to 8-10% of the total turnover¨. The technical textile sector looks set to be the ideal framework for the introduction of new functionalities resulting from the use of innovative technologies such as nanotechnology.

Nanotechnology research in textiles is rather intense and has three main objectives :

- Upgrading of both present functions and performance of textile materials, characterised by, for example, enhanced strength and tear/wear resistance, hydrophilic or hydrophobic, or insulating properties, and flame resistance.

- Introduction of innovative functionalities, not yet present in textiles. Among these are, features like antibacterial, self-cleaning, UV-blocking, conductivity, controlled release for active agents, etc.

- Development of smart/intelligent textiles, that is textiles with new functions through the integration of electronics into fabrics, which make them responsive to inputs, to show/modify specific properties, or with sensing and actuating capabilities.

The technological approaches for the production of nano-related textiles are based on the following three processes:

- Introduction of functional nano-materials into raw fibre materials, which can combine the original features of the fibre with nano-material functionality.

- Coating the surface of fibres or textiles with functional nano-materials, to produce functional textiles with greater added value.

- Electrospinning of polymers for the production of nanometric fibres leading to nonwoven fabrics with improved or new characteristics with multiple applications.

Although the applications of nanotechnology in the textile sector were initially introduced through conventional garment and furnishing textiles, the applications for high performance technical textiles are garnering increasing attention. Experts consider these segments as the main area of application for nanotechno-logies on the short-medium term, especially in sectors where performance outweighs costs (for example medical, sport/outdoor, military or niche high-fashion textiles).

At the cutting edge of the above nanotechnologies are the applications to obtain smart nanotextiles. The development of smart nanotextiles has the potential to revolutionise the functionality of our clothing and the fabrics in our surroundings giving them unprecedented characteristics, such as sensing, actuating, and communicating features.

The two sectors covered by this report, that is Medical and sport/outdoor textiles, represent a clear example of technical textiles where nanotech-nology can play a significant role in the near future. Both segments tend to prioritize performance over cost (though a cost /benefit trade off must always be found) and dedicate a considerable part of their R&D efforts in the research of new or improved functionalities. A clear example of the importance of the implementation and commercialisation of new functiona-lities in these sectors is the increasing use of nanotechnology-related anti-bacterial products.

Due to the overlapping needs of the two sectors (similar functionalities and properties required) the report focuses on product functionalities, dealing jointly with innovative textile features for both the medical and the sport/outdoor sectors, but indicating the specificities for each segment.

SCIENTIFIC AND TECHNOLOGICAL ASPECTS

State of R&D

Properties and applications of nanotechnology in the textiles sector

We have already reported, in the past, some of the most important functiona-lities required of textiles and their areas of application according to strategic research agenda of the “European technology platform (ETP) for the future of textiles and clothing”, indicating how nanotechnology is helping to achieve these desired properties.

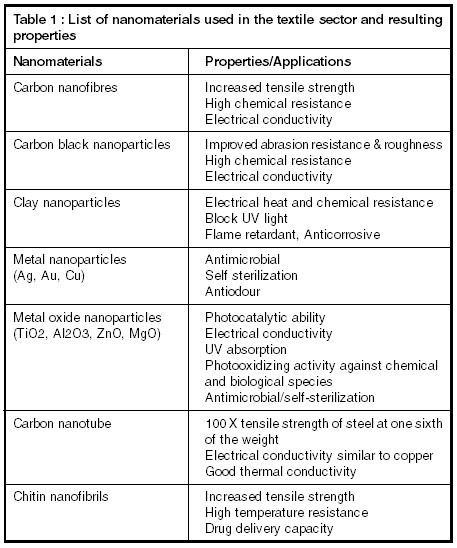

Table 1 lists some of the nanomaterials being utilised to improve the performance of textiles.

These nanoparticles may be used to develop composite fibres, as nanoscale fillers, or through a foam-forming process and may also be applied as finishing to the textile, for example spraycoating TiO2 for biological protective materials. A more detailed analysis of nanoparticles and nanotechnology applications in the textile sector can be found on.

Technologies available for the production of nanotextiles

- Textiles’ performance improvements, by means of nanotechnologies, has been obtained utilizing the following approaches:

- Fibres containing nanomaterials – Nanometric materials can be dispersed into the polymeric precursor matrix of the fibres or deposited on their surface to give new nanocomposites with improved performances and characteristics.

- Finishing treatments – Surface treatments at nanoscale, using both wet and gas phase processes, can bring about important advantages in the finishing step. The principal technologies adopted are dip coating, spray coating, sol-gel coating, low pressure and atmospheric plasma coating, and chemical vapour deposition.

- Electrospinning – Various polymers have been successfully electrospun into ultrathene fibres mostly in solvent solution and some in melt form. When the diametres of polymer fibre materials are shrunk from micrometers to nanometres there appear several amazing characteristics such as very large surface area to volume, ?exibility in surface functionalities, and superior mechanical performance (such as stiffness and tensile strength), which can lead to non-woven fabrics with improved or new characteristics having multiple applications. A particular type of electrospinning is called Nanospider™, invented by the Czech Technical University of Liberc and developed by Elmarco. This technology allows for the production of nanofibres on an industrial scale, avoiding the use of capillaries and nozzles.

Most commercially available nano-enhanced textile products (>95%), incorporate nanotechnology through finishing treatments; for example coatings containing nanoparticles, or plasma treatment of finishing goods.

New nano-enabled functionalities in textiles

The introduction of nanotechnologies in the textile world has opened the path to a huge number of applications, some resulting in a significant improvement on current functionalities but also the introduction of new features. Here follows a list of the principal new nano-enabled functionalities acquired by textiles.

Antibacterial textiles

Textiles are carriers of bacteria and fungi. Bacterial or fungal growth on fabric can be controlled by (a) finishing, using resins to fix the bacterial agents to the textile surface or (b) grafting antimicrobials/antifungal agents to the fibre chain (cellulosic, viscose, etc). Antibacterial activity is closely related to soil-repellent and soil-release qualities of textiles.

Textiles containing a biocide – The antibacterial compound, generally silver nanoparticles, but also copper or triclosan, are applied on the textile surface by dip coating with a nanosol followed by heating to remove the solvent. Alternatively, Ag nanoparticles can be applied by plasma polymerisation co-sputtering on fabrics [5-9] or they can be mixed with the textile precursor followed by melt spinning.

Textiles with photoactive properties – A fully alternative approach is based on photocatalysis. The fabric is coated with a thin layer of nanocrystalline titanium dioxide (TiO2) particles. TiO2 is a photocatalyst that when illuminated by light of energy higher than its band-gap, electrons in TiO2 jump from the valence band to the conduction band, forming an electron and an electric hole on the photocatalyst surface. Both these species react, respectively, with oxygen and water, with the formation of two unstable species, namely O2 radicals and OH radicals, which are very reactive and react with dirt and microorganisms degrading them to CO2 and water. TiO2 is mostly applied to the textile by sol-gel processing, or alternatively by chemical vapour deposition.

Ag, TiO2 and their combination are the most commonly used nanochemicals in this field, but the use of ZnO and chitosan has also been reported. In addition, the cosmetic, bacteriostatic, antifungal, and wound repair properties of chitin nanofibrils have also been studied.

Self-cleaning textiles (including water repellent)

Textiles with photoactive properties – As reported for the antibacterial textiles, the photocatalytic activity of TiO2 has been applied to fabrics also with the purpose of stain degradation. TiO2 nanoparticles are applied to a textile as dip coating, by sol-gel technique. The high energetic species produced by the catalyst when irradiated by light react with stains oxidising them to CO2 and H2O.

Textiles with super-hydrophobic properties – It is known that the wettability is strongly linked to two properties, the surface free energy and the surface roughness. Surface free energy is an intrinsic property of the material that can be controlled by chemical modification, such as fluorination or other hydrophobic coating. Fluorochemicals are chemicals capable of repelling water, oil and liquids that cause stains. Ultrahydro-phobic textiles have been prepared by modifying the surfaces with various fluorinated polymers, like PFTE, fluoroalkylsilanes, and pefluorinated polymer monolayers.

A second approach, derived from nature, is the so-called lotus effect based on the observation that lotus leaves are characterised by exceptio-nal water repellence properties because of their rough surface; a rough surface reduces the ability of water to spread out. Tiny crevices in the leaf’s surface trap air, preventing the water droplets from adhering and facilitating cleaning by the water droplets rolling off the surface picking up dirt particles.

Water repellent properties have also been obtained by means of nano-whiskers, by the socalled NanoSphere(R) technique, and by plasma coating. Superhydrophobic properties have been realised on the surface of textiles by coating them with carbon nanotubes (CNT), or with silica, silver, and calcium carbonate nanoparticles in association with non-fluorinated hydrophobic polymers.

Textiles with anti-adhesive properties – A different approach to avoid the sticking of specific compounds, like proteins, to textiles, has been the one to make their surface anti-adhesive.

Designed to the production of antihadesive wound dressing, good results have been obtained by sol-gel coating the textile with a SiO2 nanoparticle derivative.

Moisture absorbing textiles

With the aim of obtaining textiles with moisture wicking and transpiration absorbing features, fabrics have been coated with TiO2 nanoparticles. An alternate deposition onto the textile surface of TiO2 and poly(dimethyl diallylammonium chloride has been reported. Plasma techniques are also commercially used to achieve the desired functionality.

UV-blocking textiles

For many applications, mainly in the case of sport/outdoor textiles, UV-blocking properties are highly desirable. Materials reported to obtain textiles with this feature are metal oxide nanoparticles, mostly ZnO and also TiO2 or lutein by coating the fabric by means of sol-gel processing.

Tear/wear resistant textiles

The mechanical properties of textiles can be improved by the help of nanotechnologies, allowing the production of fibres and fabrics with increased strength, elasticity or tear and wear resistance. The most widely used nanomaterials for this application are carbon nanotubes (CNT). They can be mixed to many fibre precursor polymers, like polystyrene, polypropilene, polyvinyl alcohol, followed by spinning, or alternatively, applied to fabrics by spay coating or dip coating.

In addition, the textile performance can be improved using metal oxide nanoparticles, like ZnO (increased stiffness), Al2O3 (increased fracture toughness, or SiO2 (increased abrasion resistance).

Insulating textiles

With the purpose of obtaining textiles with improved insulating properties for the production of exceptional environment garments, nanoporous structures that minimise the mechanisms of thermal transport have been utilised. Particularly suitable to this purpose are aerogels, which are synthetically produced amorphous silica gels impregnated into a non-woven flexible fabric substrate, offering both the benefits of exceptional thermal performance and a flexible blanket form.

In this case, the external size of the aerogel is not necessarily at the nanoscale but the voids incorporated in the amorphous silica gel matrix are. It is the nanosized void space which gives rise to the exceptional insulation performance of these materials. The voids are filled with air, lowering the density of the material; the more air enclosed within the aerogel, the more efficient the insulation.

Conductive textiles

Traditional textiles, both natural and synthetic, are almost always insulators. The interest in transforming them into conductors arises from the need to obtaining antistatic or electromagnetic shielding garments, or for the production of the revolutionary electronic “smart” textiles.

The technologies utilized to make a textile conductive are based on the introduction into the fabric of conductive agents, like metal nanoparticles, carbon nanotubes (CNT), carbon black (CB), or conductive polymers, like polypyrrole, polyaniline, and polythiophen.

These conductive agents are introduced into fibres and fabrics using processes such as physical vapor deposition (Cu, dispersion into polymer followed by spinning(CNT) or electrospinning (CB), dip coating, vapour or solution polymerisation of conductive polymers.

The “electronic/smart textiles” are attracting increasing attention; they contain sensors, actuators and control units but still retaining the features necessary for comfortable clothing.

They may be either passive, i.e. capable of sensing the surrounding conditions, and active, i.e. containing both sensors and actuators to respond/adapt to specific inputs.

Textiles involved are natural materials, like cotton, wool and flax, and synthetic fibers, like Lycra and Kevlar, with the addition of ICPs (inherently conducting polymers), like PPY (polypyrrole) or PANi (polyaniline), and CNT (carbon nanotubes). Such fabrics are able to absorb substances from the skin or can release therapeutic or cosmetic compounds to the skin.

Textiles with controlled release agents

This type of textiles find application in many fields such as drug releasing wound dressings, insect repelling outdoors clothing, fragrance emitting clothing, moisturizers or skin care cosmetics. The nanomaterials employed in this purpose are nanoclays, like montmorillonite, which is impregnated with the active agent, or chitin nanofibrils which are complexed with active ingredient, melt compounded with a polymer followed by spinning. As an alternative, SiO2 nanosols have been used, by addition of the active species and coating of the fabric by sol-gel-processing.

Medical Textiles

Nanotechnology-related textiles can play an important role in the medical sector. Currently, woven and non-woven anti-bacterial fabrics are the most used applications of nanotechnology in the medical textiles segment, being used to prevent infection or deodorise medical clothing, wound dressing, and bedding.

The number of fields where nanotechnology-related textiles are finding applications are growing and include:

- Surgical, with surgical drapes for the aseptic techniques used in every day wound dressing, catheter changing and the like, to reduce the chances of contamination and cross-infection.

- Medical, three-dimensional textiles to prevent and reduce contact irritations and wound infections

- Prostheses, with fibres that are able to facilitate the bonding of the implant to the living bone, or with resorbable guidance devices for the regeneration of peripheral nerves.

- Dental, with textile that release medical active gases for therapeutic applications, or with multi-component nanofilament for dental care applications.

- Garments, with lightweight, flexible, lead-free X-ray shielding aprons, or clothing incorporating electronic functions to monitor biological parameters or improve the quality of life.

- Drug delivery, with drug-loaded fibres for the delivering and the controlled release of therapeutic agents.

- Fabrics surface-functionalized and utilised for tissue engineering.

- Non-woven nanofibre filters used in a variety of medical equipment, such as respiratory equipment and transfusion/dialysis machines.

- Hygiene, with composite non-wovens with improved liquid absorbing features for nappies, sanitary napkins, adult incontinence pads, panty liners, etc.

Sport/Outdoor Textiles

Sports textiles are one of the textile segments where performance is very important. These high performance characteristics are achieved making use of innovative technologies (e.g Gore-Tex nanotechnology). The use of these technologies aims to improve different product properties as well as incorporating new functionalities, some of the properties with higher importance for costumers include :

Improvement in comfort – The physiological comfort of sportswear can affect not only a wearer’s wellbeing but also his performance

Increase of protection – Protection of the wearer is of fundamental importance, dealing with: impact protection; protection against the cold; water resistance; and water vapour transfer.

Performance enhancement –Improvement of athlete’s performances; for example, the hydrodynamic characteristics of swimmers.

Addition of monitoring and training features in the textiles – The combination of sport textiles with sensor devices allows the monitoring of the athlete’s physiological conditions leading improvement in physical abilities, training status, athletic potential, and responses to various training regimens.

Combining clothing functions with wearer comfort is a growing market trend, and for all active athletes this constitutes a vital factor for achieving a high performance level. The sports industry has driven a lot of research within the textile industry towards improving athletic performance, personal comfort, and protection from the elements. To reach the above goals, innovative fibres and fabrics, including high performance and high functional fibres, smart and intelligent textiles and coated and laminated textiles have been utilised. Synthetics that were once thought to be inferior to natural fabrics now boast high performance characteristics.

Additionally, the application of nanotechnology and combination of electronics and textiles make the manufacturing of clothing, with integrated heating elements or fabrics for example, which stimulate muscles.

The technical developments in the sports clothing industry have resulted in the use of engineered textiles for highly specialised performances in different sports. With highly functional and smart materials providing such a strong focus in the textile industry generally, companies are increasingly looking for ‘value added’ textiles and functional design in sportswear as well as intelligent textiles, which monitor performance with in-built sensors.

Nanotechnology used to improve textile performance on sport & outdoor applications

Following are some of the principal “nano-tools” applied to improve textile performance in the sport/outdoor applications :

- Carbon nanofibres are used to increase the tensile strength, improve the chemical resistance, and to introduce electrical conductivity.

- Carbon black nanoparticles are used to improve the abrasion resistance and toughness, to increase chemical resistance and to introduce electrical conductivity.

- Carbon nanotubes are used to impart outstanding increase of tensile strength, electric conductivity similar to copper and good thermal conductivity.

- Clay nanoparticles are used to increase electrical, heat and chemical resistance, as flame retardant and anticorrosive, and as blocker of UV light.

- Metal and metal oxide nanoparticles (Ag, Au, Cu, TiO2, Al2O3, ZnO, MgO) are used to impart photocatalytic activity, electrical conductivity, UV absorption, and antimicrobial properties to textiles.

Additional Demand for Research

The application of nanotechnology to the textile sector has great potential, but the success of nano-enabled developments is linked to the relative weight of the drivers and barriers, and consequent cost/benefit ratio, that can vary according to the sector of application. The trade off between them will determine the rate of their success, but it must be also be noted that nanoenabled innovations will often compete with other, more conventional, approaches.

Therefore there is a constant demand for additional research along the nanotextiles value chain; to clarify base principle and mechanisms of action, for example the size/quantity-related properties, surface interaction or nanoparticles diffusion/distribution into a polymeric matrix; to improve effectiveness, scalability and industria-lization of processes and procedures; to adapt nano–related processes and products to existing equipment and procedures, to reduce costs.

Also the quest to enlarge the sectors of application of nano – related functionalities/properties ask for a continuous effort of research.

The challenges are many and require both basic and application oriented research.

Another field with a growing demand for research is related to the possible health and environmental hazards potentially associated with nanoparticles along the entire life cycle of nano-textiles. Rigorous control of the interaction of nanomaterials with the human body and the environment is mandatory. Thus, integrated research strategies bridging preclinical-clinical gaps must to be combined with physico-chemical characterization of the material, in vitro, in vivo and ex-vivo mechanistic studies, toxicogenomic analysis, biokinetics and molecular interactions investigated by biophonic methods, goal-driven risk/benefits assessment and firstin-human studies with Investigational New Drugs (INDs).

Applications and Perspectives

Publicly available Nanotechnology-based Consumer Products

The Project on Emerging Nanotechno-logies was established in April 2005 as a partnership between the Woodrow Wilson International Centre for Scholars and the Pew Charitable Trusts. It has produced the first publicly available on-line inventory of nanotechnology-based consumer products.

As of August 25, 2009, the nanotech-nology consumer products inventory contains 1015 products or product lines. The inventory has grown by nearly 379 % (from 212 to 1015 products) since it was released in March 2006.

Products have been grouped according to relevant main categories that are loosely based on publicly available consumer product classification systems.

The largest main category is Health & Fitness, with a total of 605 products, followed by Home & Garden (152), Food & Beverage (98), Automotive (68), Electronics & Computer (57), etc.

The sub-categories associated with the largest main category, Health and Fitness, include Cosmetics (137 products), Clothing (155), Personal Care (193), Sporting Goods (93), Sunscreen (33), and Filtration (43). Again, products with relevance to multiple categories have been accounted for multiple times. The Cosmetics, Clothing and Personal Care sub-categories are now the largest in the inventory.

The breakdown of products by region indicates that companies based in the United States produce most of the products, with a total of 540, followed by companies in East Asia (including China, Taiwan, Korea, Japan) (240), Europe (UK, France, Germany, Finland, Switzerland, Italy, Sweden, Denmark, The Netherlands) (154), and elsewhere around the world (Australia, Canada, Mexico, Israel, New Zealand, Malaysia, Thailand, Singapore, The Philippines, Malaysia) (66).

The most common nanomaterial mentioned in the product descriptions is nanosilver (259 products). Carbon, which includes fullerenes, is the second most referenced (82), followed by titanium (including titanium dioxide) (50), silica (35), zinc (including zinc oxide) (30), and gold (27).

European study of products containing nanoparticles (BEUC & ANEC)

In Europe, BEUC (The European Consumers’ Organisation) and ANEC (The European Consumer Voice in Standardisation) have published a non-exhaustive inventory of products claiming to contain nanoparticles that are available on the EU market. The purpose is to prepare a public debate to gather knowledge about benefits and risks for health and the environment given by such materials.

The study has identified 110 products, divided by sector as follows: Cosmetic products (52); Food products (10); Products used by children (5); Other products (43). Belonging to the last group are some textiles of interest to our report:

- 100% cotton sheet set (AgActive, UK). Sheet able to kill over 99% of bacteria including MRSA (Methicillin Resistant Staphylococcus Aureus).

- AgActive Towel (AgActive, UK); Cotton towel treated the silver treatment “SilverSure” to become bacterial and odour free.

- Acticoat antimicrobial barrier dressing (Acticoat, UK), Antimicrobial barrier dressing for use over wounds using the patented silver technology “Sylcryst” nanocrystalline.

- Nanotech Coolest Comfort (Nano-Tex, USA); Fabric that balances body temperature, retains natural softness and breathes naturally.

- Men’s no-iron comfort waist plain front chinos (Land’s End, UK); Clothing made with NanoTex finish that resists spills and wrinkles.

- Solefresh nanosilver Socks (SoleFresh, UK); Non-toxic, non-allergic socks preventing foot odour and some foot diseases.

- Shoes Annapolis (Timberland, USA) Shoes Agion treated footbed to inhibit growth of odour causing bacteria.

From these two studies it can be concluded that textiles is one of the sectors where nanotechnology is having a larger impact. More specifically Sports and outdoors is the segment with more products. It is also clear that nanosilver is the most widely used nanoparticle, with the anti-bacterial property representing the most common functionality provided by nanoenhanced textiles.

Nanotechnology product applications in medical/healthcare textiles

In the medical/healthcare sector the nanomaterial principally utilised are silver nanoparticles, for their recognised antibacterial activity.

Antibacterial textiles

The applications in the medical sector cover the range of antibacterial textiles with a broadspectrum of antimicrobial activity and the absence of drug resistance, capable to prevent mite sensitization in atopic dermatitis; anti-bacterial wound dressings, patient dresses, bed lines or reusable surgical gloves and masks. But they can be extended also to protective facemasks and suits against biohazards or to toothbrushes.

The need to sanitise clothing, and and many other everyday items, has resulted in the extension of the antibacterial war to many other objects such as sports clothing, domestic and automotive interior textiles, and toys. The antibacterial activity of these textiles is utilised, in particular, to produce anti-odour clothes for the sport/outdoor and furniture sectors. In addition, possible uses of antibacterial textiles are considered for the household products such as kitchen clothes, sponges or towels.

Antimicrobial wound dressings

This is a very important application of nanotechnology in the medical field. Wound dressings are manufactured by means of a bi-layer of silver-coated, high-density polyethylene mesh with a rayon adsorptive polyester core. The dressing delivers nanocrystalline silver from a nonadherent, non-abrasive surface. In vitro studies have shown that the sustained release of this ionized nanocrystalline silver maintains an effective anti-bacterial and fungicidal activity. In addition, nanocrystalline silver dressings have been clinically tested in a variety of patients with burn wounds, ulcers and other nonhealing wounds facilitating wound care by adequate debridement, and bacterial and moisture balance.

Wound dressings have been also developed, which combine an electrospun polyurethane nanofibrous membrane and silk fibroin nanofibres. These electrospun materials are characterized by a wide range of pore size distribution, high porosity, and high surface area-tovolume ratio, which are favourable parameters for cell attachment, growth and proliferation.

The porous structure is particularly important for fluid exudation from the wound, avoiding wound desiccation, and impairing exogenous microorga-nism infection.

Anti-adhesive wound dressings

Textile wound dressings such as plasters or bandages find wide range of uses in medical applications to cover wounds until the healing process can protect the wound against external environmental attack. Traditional wound dressings, generally adhere to the healing wound, causing a new injury on removal, and thereby interrupting the healing process. The close control over fibre architecture offered by embroidery is also of potential interest for highly loaded structures, enabling fibres to be placed in the position and with orientations necessary to optimize strength and stiffness locally.

The textile surface of these wound dressings is also of importance for comfort and prevention of mechanical irritation Innovative wound dressings with anti-adhesive properties to the healing wound have been obtained by coating the common viscose bandages with silica nanosol modified with longchained alkyltrialkoxysilanes.

An additional, not secondary, feature of the above innovative wound dressings is their ability in water uptake. Good absorption properties for the wound exudates are of great help to the healing process and are of special value for bedridden patients with chronic wounds.

Medical Smart Textiles

Textiles provide an excellent substrate for integration with electronic devices, including sensing, monitoring and information processing tools, able to react to the conditions and stimuli, like the mechanical, thermal, chemical, electrical, transmitted by the wearer.

The healthcare field could take advantage of these smart textiles to provide for a patient’s extended monitoring during a long rehabilitation perios. In this field a new class of electrically conductive material, called Quantum Tunnelling Composite (QTC) is being produced by the UK based Peratech. QTC has the unique ability to smoothly change from an electrical insulator to a metal-like conductor when placed under a pressure; these features will find a number of medical applications including blood pressure control, respiratory monitoring, and sensing in prosthetic socket.

Nanotechnology product applic-tions for the sport/outdoor sector

Apart from the application of smart textiles as futuristic aids for the improvement of the sport performance, that will be dealt with later, many are the interventions of nanotechnology in the production of sport/outdoor clothing. Here we have included some of the currently available products, grouped according to their main functionality.

Stain Resistance/Water repellence

Stain resistant and water repellence finishing is probably the largest nanotechnological application in textiles. Its market is no longer considered as niche, since its request is not limited to the sport/outdoor clothing, but extends also to work, casual, and evening wear. The desired textile performance has been obtained by different technological approaches, such as coating with perfluoro-chemicals, silica nanoparticles, carbon nanotubes, or with the dirt destroying photocatalyst TiO2.

Products examples :

- Hi-tech Ion-mask – Technology: Plasma Ion mask (P2i)

- Nike Lunar Wood TZ – Technology: Plasma Ion mask (P2i)

- Ecco Biom running shoe – Technology: Plasma Ion mask (P2i)

- Magnum boots – Technology: Plasma Ion mask (P2i)

- Adidas Golf shoes – Technology: Plasma Ion mask (P2i)

- New Balance Performance Outerwear vintage-inspired Circa-V outerwear line – Technology: NANOTEX outdoor (NANOTEX)

- Odlo Jacket – Technology: water resistance (HeiQ)

- Cloudveil Switchback jacket – Technology: Lotus effect – Nanosphere – (Clariant – Schoeller)

Antibacterial/Odour Control

Odour control in sport/outdoor clothing is an important topic. Such control can be achieved in different ways, such as by covering up the odour with a fragrance, by removing the odour molecules as they are formed, or applying an antimicrobial finishing.

In the first approach, odours are covered with fragrances by means of microcapsules containing fragrances that can be applied to the fabric to provide a slow release over time.

In the second approach are used cyclodextrines. These are compounds with a peculiar structure characterised by a hydrophilic surface and a hydrophobic cavity. The odour molecules, being hydrophobic, become trapped in the cavities of the cyclodextrine and are removed during laundering.

In the third approach the problem is paced at its root. Being odours formed as result of bacterial growth, the application of antibacterial finishing to the fabric is able to prevent bacterial growth and consequently the odour formation. This topic has been previously treated in the Medical Textiles chapter.

Product examples :

- Puckskin – Bamboo Athletic Socks / Short Sleeve Top / Long Sleeve Top / Long Pants/Sleeveless Top

- Extera Taekwondo Uniform – Culture Maker Corp.

- Wigwam socks – Technology: Smart silver (NanoHorizons)

- AgActive Antibacterial Socks

- Greenyarn’s socks – Eco-Fabric (Greenyarn)

- Funtional sport wear – Sinotextiles Co.Ltd.

- Lexon Nano-Silver Sock

Moisture management

Synthetic fabrics and resin treated (e.g. to become wrinkle free) are hydrophobic; however, by nanotechnological treatment these fabrics become able to absorb moisture, pulling away perspiration from the body and allowing the wearer dry and comfortable.

Product examples :

- Adidas Yocum activewear line – Technology: NANOTEX coolest comfort – (NANOTEX)

- Plasma Mec (MECTEX)

- CW-X Compression support socks -Technology: Healtha+® (Ventex)

Strength/wear resistance

Product example

Adidas Nanotech Shoe. The Lone Star is the world’s first asymmetrical 400m spike, featuring the first ever full-length carbon nanotubes reinforced plate.

Prototypes

Conducting textile platform based on novel e-fibres.

The presented prototypes are coated yarns, fabrics or simple garment containing the coated fibres to demonstrate electric conductivity whilst maintaining an original haptics. A lowpressure plasma sputtering process is used to coat a 100-200 nm thick metal coating on common monofil- or multifil- yarns, which thereby do not change their properties, but become reliably conductive for low-current signals; this includes audio signals, computer interfaces (e.g. USB), low current supply, or, dissipative heating.

Smart Textiles for Sport Clothing

In addition to the above features finalised to increase the athlete’s comfort, the sport garments are asked to be equipped also with sensors to provide information about the athlete’s physiological conditions (physical abilities, training status, athletic potential and responses to various training regimens).

Strain sensors, made from piezoelectric materials may be used to detect posture, improve movement performance and reduce injuries. The stress and strain applied to the fabric by the athlete’s movement will affect the conductivity, allowing the monitoring of body kinematics.

Examples of such applications are: a garment for the athlete’s kinesthetic monitoring, developed at the University of Pisa, for the detection of posture, improvement of movement performa-nce, and reduction of injuries; an Intelligent Knee Sleeve, developed at the University of Wollongong and CSIRO, for the monitoring of the wearer’s knee joint motion during jumping and landing to reinforce the correct landing technique; a sensor applied close to the athlete’s rib cage for the breathing monitoring, or in smart insoles for the monitoring of plantar pressure. The integration of chemical sensors into textiles for the analysis in real time of the sweat composition is also an appealing prospect.

Current situation within EU

The development of technical textiles is very dependent on the global economic climate, and given the current crisis, they are likely to grow less in the coming months. Nevertheless, the sector remains the most dynamic in the textile sector today in Europe.

It seems crucial that European businesses specialising in technical textiles should better identify the needs of the sector to support the efforts to grow and innovate, and to allow some businesses to begin the required transfer from “classical” textile and clothing products towards more technical, and therefore higher value added products.

As the technical textile industry is mostly made up of SMEs, who do not have sufficient resources for an intense R&D activity in house, it is important for public R&D structures to promoting links of collaborative research with industry. The European Technology Platform for the Future of Textiles and Clothing by 2020 plays an important role in this direction.

According to Euratex 2008 Annual Report, the technical textile industry will also have to increase its efforts to formulate European standards in order to define an adequate regulatory framework to assure a sustainable production that conforms to the wishes and needs of the consumers.

Medical/healthcare textiles

Europe holds an important position in this sector with companies active in UK (JR Nanotech), Ireland (Alltracell Pharmaceuticals), and Czech Republic (Elmarco/Nanopeutics). Important competitors in the rest of the world are located in Japan (Takeda Chemical Industries, Osaka), USA (Nanotech Institute, University of Texas, Dallas), Canada (Nucryst Pharmceuticals), South Korea (Chonbang Co.), and China (Fountain Set, Hong Kong).

Sport/outdoor textiles

The nanotechnology applications in sports/outdoor textiles see the USA as the clear leader.

Important players in this sector are: Nike, Adidas, VF, New Balance, ARC Outdoor, W.L Gore Associates, NanoHorizons, Nano-Tex, GreenYarn. Active in Europe are, among others, textiles nanotechnology specialized companies such as Mectex (IT), P2i (UK), and Schoeller (CH). Other players in the rest of world include Thomson Research (Canada), Hyosung (South Korea), Suzutora (Japan), and NanoGroup Holdings (China).

Economic aspects

General market description : European textile sector

Technical textiles have seen their share of production grow considerably in Europe over the last fifteen years, increasing constantly both in value and in volume. This market has increased from 65 to 85 billion Euros from 1995 to 2005. 8.5 million tonnes, about half of global technical textile production, is consumed in Asia, followed by US and Europe with 5.8 million and 4.8 million tonnes respectively. In Europe four countries consume about half of the technical textiles in terms of value: Germany, France, the UK and Italy. The technical textiles industry in Germany represents 45% of the European textile industry, followed by France (30%), UK (30%) and Italy (12%). Europe is one of the world leading exporters of textiles; according to EURATEX, the annual turnover of the textile industry in 2008 was over Euros203 Billion and the sector employed 2.3 million workers in more than 145,000 companies (mainly SMEs).

However, over the last couple of decades the European textile sector has dropped its production due to the globalisation of the economy and the relocation of the European companies outside Europe. These circumstances have worsened due to the world economic crisis that started in 2008 and almost 68,000 textiles jobs have been lost. During the first quarter of 2009 this negative trend has continued and production of the textile industry production dropped 23% on average.

Medical textiles

The global market in 2007 for medical textiles was about $8 billion. Every year this niche market becomes more relevant and its importance will increase even more in the future, the forecast world consumption in volume of medical textiles for 2010 is shown in the figure above.

The increase of population over 60 years in Europe and consequently the increase of doctor visits is the main problem that new technologies will have to cope in order to assure a good medical service. Currently patients are offered periodic visits to the doctor and prescription medicine. However, the incorporation of nanotechnology in textiles may boost the so-called “telemedicine” (use of sensors and telecommunications in textiles to transfer medical information with the aim of consulting and remote medical measures or examinations).

Moreover, the nanocoating textiles can offer a longer textile lifetime within the body and therefore visits to health facilities to replace dressings may be less frequent.

Health and hygiene textile materials have a wide variety of uses; however, nano-enabled developments remain in the early stages of development. The products range from simple gauze or bandage materials to scaffolds for tissue culturing and a large variety of prostheses for permanent body implants. The huge number of categories where the medical textiles can be applied, and the additional fields of applications regarding personal wellness that will emerge in the future, will drive growth in the number of nanotechnology products in the sector.

However, there remains concern about the safety of nanoparticles introduced in the human body.

Sports and outdoors

The sports and outdoor textiles market is an important and growing sector within the technical textiles subsector. In 2008 around 10% of the Europe consumers’ expenditure on clothes was on sports clothing with the figure rising to 19% when considering sports footwear and clothing. These values show the importance of this segment to the overall textile sector.

The outdoor sector is one of the textile sectors where the impact of the economic crisis is lower. According to the German Sports Retailers (VDS) the market for sport outdoor products grew 11% on 2008 and the values from 2009 show that the growth remains stable. Proof of the potential for the outdoor sector is that big sports companies (even accounting for the global economic crisis), who focus their activities in traditional sports goods, are starting to position themselves within the “performance-sports gear” releasing new products aimed at the outdoor market.

Athletic apparel – Global Market share (Commerzbank equity research 2008)

- Nike 7%

- Adidas 6%

- Reebok 2%

- Quicksilver 2%

- VF Knitwear 3%

- Columbia 2%

- Puma 2%

- Others 76%

The above data reveal the market for athletic apparel in 2008; the top five firms control only the 20% of the market. According to the a market research company NPD Group, Inc., worldwide sales of sports equipment, apparel, and footwear in 2008 achieved Euros 219 billion (almost 75% in textiles). Nike and Adidas are the two market leaders in this sector with sales of around $18,6 billion (Nike) and $10,8 billion (Adidas) in 2008. Values do not differentiate turnover based on sales from textiles or other sports goods. VF (which owns brands like North Face) and Columbia are other key players in the outdoors segment.

Turnover from world market leaders in the sports & outdoor sector

- Nike $18.6 billion

- Adidas $10.8 billion

- VF $7.6 billion

- Puma $2.5 billion

- Quicksilver $2.26 billion

- Pentland Group $2.04 billion Sketchers $1.44 billion

- Columbia $1.32 billion

- Under Armour $0.73 billion

European and US companies have for decades been leaders in the textile sector; however, Chinese companies are gaining market share rapidly with an annual growth over the past 2 years of 40%.

All these facts (e.g. high growth of the performance-sports goods, steadily growth in the past years, etc.) confirm that the sports and outdoor segment, due to its capability of increasing textile performance, is one of the key textile sectors where nanotechnology can play a major role in the coming years.

Drivers and barriers

Innovative medical textiles and sport/outdoors textiles will be one of the main concerns/priorities for the coming years. Nanotechnology brings to these textile products the opportunity to fulfil their performance requirements while retaining key characteristics such as aesthetic properties and comfort level.

In the case of sports and outdoor textiles the main features required by customers are related to comfort: water repellence to keep the body dry; moisture management (e.g. moisture wicking, quick drying); anti-bacterial/anti-odour; UV protection; and wind resistance.

Nano-enabled products can meet all these customer demands. In the past, several large sport and outdoor brands incorporated functional nano-coating technology in some products and this has result in a boost of confidence of SMEs in nanotechnology as the brands noticed that the use of nanotechnology was a good marketing tool. However, in the past few years some countries have noticed an uncertainty with respect to potential health hazards. As it has not been proven beyond doubt whether nanoparticles/nanomaterials are harmful or not, uncertainty remains.

Furthermore, medical textiles must fulfil specific characteristics related to non-toxicity, noncarcinogenic, non-allergic and sterilisation capability, without suffering chemical or physical damage. These performance require-ments represent the main driver to use nanotechnology as a promising way of obtaining the desired performance requirements while retaining the key textile features/properties.

However, there are still several barriers that must be overcome in order to make nanotechnology a common technology within the sports/outdoor and medical textiles sectors. These barriers are the environmental and health factor and legislation, which is not clear for a product incorporating nanotechnology.

The environmental factor is a key aspect to take into account. Nanotech-nologies can have beneficial effects on the environment, but their use can also raise concerns for the potential harmful impact on it. During the last few years environmental legislation has forced the textile industry to address concerns about the possibility to change current textile processes to others with greater efficiency and a lower environmental impact. On one hand, the main issues of the textile industry are the high water and energy consumption, the genera-tion of huge amounts of effluents with high chemical oxygen demand, and excessive colour. With wet dyeing processes like plasma treatments, the fibre surface of the material can be modified to reach the endproperties without less industrial wastes and using less water. On the other hand, textiles with nanoparticles (nano-metals) in the fibres or in a coating can make their disposal and the recycling process more difficult.

Another factor, mentioned above, is the potential risk for human health of textiles incorporating nanotech-nologies. The need to assure the safety for the wearer of these types of garments is fundamental for the acceptance/success of these products on the open market.

Regarding legislation in the field, it applies in the same way conventional materials and nanomaterials; however, the laws should distinguish them because they can behave very differently. As mentioned before, there are concerns about the effects of nanomaterials and the methods currently used to assess risks are unsuitable for testing nanomaterials, that’s why if the law says that companies can only place products on the market if they are safe, it will not always be easy to determine whether a particular nano-based product is danger or not.

Stakeholders tend to think that existing laws are inadequate and are not always clear for a product incorporating nanomaterials.

Boundary conditions

The boundary conditions include :

- Technical limitations of nanotechnology – State of the art of the technology.

- Cost – production costs increase.

- Lack of knowledge about nanotechnology opportunities and scepticism about their benefits.

The technical limitations include: issues with scale-up of the process; reproducibility of results; availability of raw materials; and production of materials with long lasting effects. To overcome these limitations it is neccessary to invest in R&D, to create prototypes, and to develop large scale processes. Other concerns of the textile industry include low compatibility of new production processes with current production processes and the insufficient production capacity of the new production methods.

Another key limitation for a wider use of nanotechnology is related to the production costs of nanotechno-logy-enabled products. Nanotechno-logy production costs are higher than traditional production costs. These high costs are not only related to the investment on (expensive) equipment, but also to the hiring of expertise, (nanotech experienced resources, capable to operate the equipment) and use of expensive raw materials for example. Despite sports/outdoor and medical textiles being less sensitive to the increase of cost than the clothing sector, the production costs remains as one of the most important factor avoiding a wider use of nanotechnology.

Finally, the lack of knowledge about the technology and the processes results into a limitation of further use of nanotech processes in the textile industry. Most of the companies (end-users) are aware of the existence of nanotechnology and their potential, but they still have doubts about how this technology can be implemented in their products/processes and whether the required investment will be recouped.

Some leading sources from the textile nanotech sector have stated that people tend to associate nanotech-nology to nanoparticles and complex technology processes, assuming that it would be very difficult to implement this new technology into their production lines and that it would require a large investment in expertise and machinery. However, reality shows that when the results are presented and production processes are explained in detail, this initial hesitation disappears.

Amongst the measures being taken in order to overcome the insecurity in utilising nanotechnologies, due to advertising messages insinuating nanotechnology is not healthy, could be labelling. However, at the moment, there is not a generally accepted regulation for it at European level. In Germany the Hohenstein Institutes in conjunction with Nanomat have created a standard to enhance the brand value and facilitate the access of new products to the market (the so called Hohenstein Quality label for Nanotechnology). Product labels convey certain quality properties to consumers as breathability, skin compatibility, abrasion resistance and wash resistance, in addition to evaluation of the nanostructure and its function.

Furthermore, the Hohenstein Quality Label provides the opportunity to stand out from all the textiles that claim to be “nano” and are not.

Economic information & analysis

Nanotechnology enabled products, still represent a very minor part of the total market of sports and outdoor textiles (around 1-2%). One reason that can explain the small contribution of nanotechnology in the final product, as mentioned before, is the increase of the final price.

Some experts point out that the use of nanotechnology can increase the cost by 0.1 Euro/m2 of textile in the textile industry or by 2-3 euros per shoe.

Nano-enabled developments in textiles include developing new (nano) fibres and yarns or in the fabric or in the finishing. However, regarding the textile value chain, the advances in fabric finishes have contributed to the implementation of nanotechnology developments in textiles because the margin in the final steps of the textile value chain is higher than in the production of new nano-fibre where the prices are much more competitive. Some nanomanufacturers have identified the finishing and the textile product as a market opportunity and they are already selling their nanotechonology to such clients (see Figure given above).

An example that clearly reflects the situation of nanotechnology in the sports and outdoor textile segment is the case of P2i and their Ion Mask. During 2009 the first products incorporating Ion Mask technology were released onto the market (around 0.5 million Hi-Tech shoes incorporating P2i’s plasma treatment are already on the market). However, in the past months the company has reached agreements with some of the world leading sports and outdoors brands (Adidas, Nike) to commercialise new products incorporating Ion Mask. These new agreements will result in a significant growth of the number of products on the market that incorporate P2i technology.

An example that clearly reflects the situation of nanotechnology in the sports and outdoor textile segment is the case of P2i and their Ion Mask. During 2009 the first products incorporating Ion Mask technology were released onto the market (around 0.5 million Hi-Tech shoes incorporating P2i’s plasma treatment are already on the market). However, in the past months the company has reached agreements with some of the world leading sports and outdoors brands (Adidas, Nike) to commercialise new products incorporating Ion Mask. These new agreements will result in a significant growth of the number of products on the market that incorporate P2i technology.

In figure (above) the different functionalities (resulting from the use of nanotechnology) available in the sports and outdoor segment are presented. The figure presents, qualitatively, the relative market penetration and the potential adoption of (market interest in) nanotechnology. The size of the bubble indicates, again qualitatively, the number of products in the market incorporating a specific feature. The figure reflects that there is a major consumer interest in products incorporating moisture management and hydrophobicity; however, the largest numbers of products possess these two functiona-lities so this may be expected.

US companies were first to concentr-ate their efforts in the sports/outdoor sector but during the past 5 years the European sports and outdoors industry has rapidly evolved to allow it to compete with USA manufacturers. This has resulted in the creation of some new companies and the reorien-tation of already existing companies. In some cases these manufacturers are licensing their technologies to larger sports and outdoors companies, such as Nike, Adidas or VF.

In the case of Medical textiles the market penetration is significantly lower (less than 1% of the total market share). This market segment has a very high potential but nowadays the use of nanotechnology in this field is limited to nanosilver-enabled products (for example wound care products and other minor applications making use of antibacterial properties).

The value chain for medical textiles is similar to that of sports/outdoors textiles; retailers deliver products for which the customer is willing to pay more than the sum of the cost activities in the value chain, that means that if the nanotechnology can be implemented in the later stage the cost of early stage activities will not be altered.

(Courtesy : AIRI/Nanotec IT and Bax & Willems Consulting Venturing)