Smart-Indigo™: High sustainability; Reduced health hazards; Savings in wastewater treatment and energy; Better colour consistency and performance; More ecological and economical; Easy to handle and more efficient

During one year over 15 billion meters of denim fabric are produced. Most of the production takes place in countries like China (52%), India & Pakistan (15%), Mexico & Brazil (13%), Europe & Turkey & Middle East (7%), USA & Canada (4%), rest of the world (9%).

The demand for denim continues to grow, with each of us already owning four or more denim fashion items. 66’000 tons of indigo powder is needed to produce 15 billion meters of denim fabrics to different shades of blue. The famous blue indigo is a powder which needs hazardous chemicals to make it water soluble for the dyeing process.

After dyeing, tons of wastewater containing these chemicals is discharged into the environment often without treatment. The excessive damages caused by those chemicals and heavy metals, like cadmium, chromium, mercury, lead, and copper are harmful to humans, animals and the environment.

Furthermore chemicals left on the denim fabrics after industrial washing can still effect our skin. Imagine wearing denims which are contaminated with chemicals! The denim dyeing process is one of the major pollution problems within the textile industry.

Time for a change.

SmartIndigo™ will resolve these issues. This Swiss invention which utilises a 100yearold discovery (A. Brochet, 1917) becomes reality. Tons of leucoindigo can be produced without chemicals.

Smart-Indigo™: Because It Makes A Difference

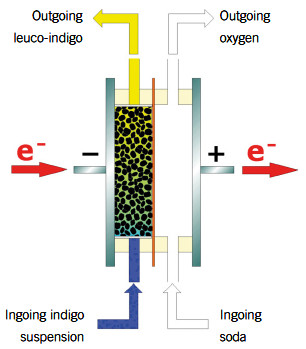

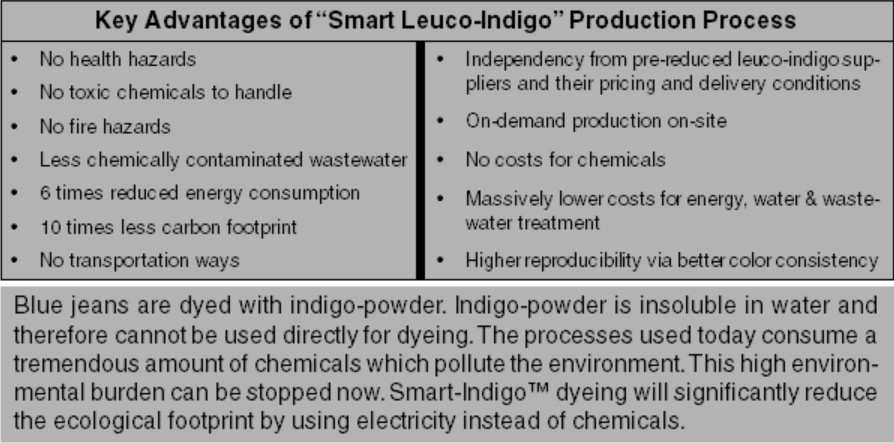

“Smart LeucoIndigo” is produced in an electrochemical process consuming considerably fewer resources than existing methods. Using only indigo pigment, caustic soda, water and electricity. This technology is the most environmentally friendly process to dye denim. SmartIndigo™ is a global innovation and will markedly reduce the ecological footprint.

Behind this technology are experienced specialists in the dyeing and finishing industry. Located in Switzerland, represented globally, with established and innovative products selling all over the world. Time to market for this development, replacing chemicals with electricity was 5 years in the making. Two years longer than originally planned “-Nothing good comes easy- kept us awake more than once through desperate nights.” Mr. Herbert Guebeli, managing director says. This resulting clean technology now speaks for itself. It makes a difference.

Smart-Indigo™

Smart-Indigo™ stands for an industrially proven technology, which will make a difference by bringing a revolutionary change to the global denim dyeing industry. Combining benefits for the environment, the people and the producers of denim items.

Makes more from less

This revolutionary leuco-indigo process opens up a whole new range of opportunities.

- Electricity instead of chemicals

- High sustainability

- More ecological and economical

- Reduced health hazards

- Better colour consistency and performance

- Savings in wastewater treatment and energy

- Easy to handle and more efficient

Electricity Instead Of Chemicals

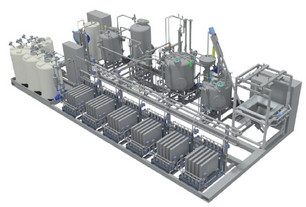

Smart leuco-indigo production on-site

Machine specification

• Dimensions approx.: 12 × 5.5 × 4.0 m (l × w × h)

• Capacity: 1 ton Smart-Indigo™ (30%) per day Transformation of approx. 100 tons of indigo powder (grain) per year

• Electricity consumption Approx. 650 KWh to produce 1 ton Smart-Indigo™ (30%)

“Smart Leuco-Indigo” is produced by electrochemical process consuming considerably fewer resources than existing methods. Using only indigo pigment, caustic soda, water and electricity. In a fully automated process, the clean Leuco-Indigo is produced, metered and fed directly to the dye bath. The Smart-Indigo™ solution is the most sustainable way to dye denim.

Without

- Chemicals

- Environmental burdens

- Health hazards

- Long transportation ways

Using

- Indigo pigment

- Water

- Caustic soda

- Electricity

Discharging only

- Oxygen

Key Advantages:

- Massively reduced pollution; Healthier and safer work places; Favorable production.

- Smart Indigo process is, therefore, good for the planet, people and profit.

Savio Group

Sedo Engineering is part of the Savio Group. Cutting-edge technology and excellent solutions for the textile industry in spinning, weaving and dyeing/finishing.

- 5 Business areas

- 11 Facilities worldwide

- 221 agents in 102 countries

- 1495 employees worldwide

Sedo Engineering SA

Being experienced specialists in the dyeing industry, we guarantee Swiss quality standards and highest reliability. Industrial enterprises utilising our groundbreaking and proven technology will be at the forefront of denim dyeing industry. On top of that, you will protect the environment and create a safer workplace. Because it makes a difference!

Sedo Engineering SA

Rue du Village 7, 1908 Riddes VS, Switzerland

+41 27 306 80 80 info@smartindigo.com www.smartindigo.com