Dr. Naresh M. Saraf (Supertex-Sarex, Mumbai, India)

Finishes that repel water, oil, and dirt are important in all parts of the textiles market for clothing, home and technical textiles. Water repellency is achieved by using different product groups, but oil repellency is attained only by application of fluorocarbon polymers. The later are modified to have a wide range of properties to fulfill the different demands of the consumers and the intended purpose. The oldest repellent finish is to repel water. Fluorochemical repellents are unique because they confer both oil- and water- repellency to fabrics. The ability of fluorochemicals to repel oil is related to their low surface energy that depends on the structure of the fluorocarbon segment, the non- fluorinated segment of the molecule, the orientation of the fluorocarbon tail, and the distribution and amount of fluorocarbon moiety on fibres. Fluoropolymers suited for textile finishing generally consist of a polymeric backbone of acrylate or polyurethane, with fluorinated side chains. Their effectiveness for each application varies with the chain length, the shape of the chain and the type of end groups. A perfluroinated compound that has frequently been part of product formulations for hydrophobisation of textiles is perfluorooctanoic acid (PFOA), which is a chemically-stable surfactant.

The main aim of the textile finishers today is to make these finishes more durable and comfortable to wear. Durable water repellent (DWR) finishes are applied to fabrics which extend the life of the products in addition to providing protection against water, oil and soil. The excellent water repellency provided by the fluorochemicals impedes the access of the washing liquor during laundering.

Careguard-66 (New) is a new generation water and oil repelling fluorocarbon based on C6 Chemistry. It imparts durable water and oil repelling effects on various substrates viz., polyester, cotton, nylon, wool fibres and their blends without affecting the original hand of fabric. It can be applied by padding foam and by spray technique.

DWR technology has historically been achieved with textile finishes that contain a polymer to which long-chain perfluoroalkyl groups (termed as “C8”). These C8 fluorinated polymers often contain trace levels of long-chain perfluoroalkyl acids (PFAAs) as impurities. Long-chain PFAAs including perfluorooctanoic acid (PFOA) and perfluoroctane sulfonate (PFOS) possess toxicological properties of concern. For ecological reasons, the fluorocarbon polymer technology is increasingly under pressure. With increasing demand for eco-friendly products, the first change was to move from perfluorinated chemicals based on C8 chemistry to perfluorinated chemicals based on C6 chemistry thereby eliminating PFOA/PFOS release into the environment. Sarex has developed PFOA and PFOS free fluorocarbon, Careguard-66 (New) water and oil repellent which is based on C6 chemistry.

Unique features of Careguard-66 (New)

- Offers good water and oil repellency performance levels

- Applicable on cotton, polyester and its blends

- Durable to 20 Home Launderings

- Finished fabric does not impair softness

- PFOA below detectable limit hence eco-friendly

Materials and Methods

Substrate : 100% Cotton Bottom weight, Polyester/Cellulosic blend, 100% Polyester, Bulk finished Polyester, Bulk finished Nylon

Chemicals : Careguard – 66 (New)

Experimental

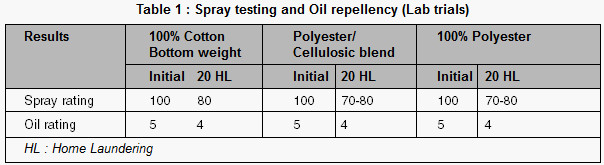

Padding application : Fabric substrate was padded with required concentration of Careguard-66 (New) with the pick-up of 65-70%. The concentration of Careguard-66 (New) varied according to the fabric substrate and durability. The bath pH was adjusted to 4.0-4.5. After padding, the fabric was dried at 100-120°C followed by curing at 170°C for 1-2 min. The finished fabrics were evaluated for Spray testing as per M&S C50 and Oil repellency as per M&S P23.

It is recommended to pre-wash the substrate to be treated with 1g/l Saragen-DAM at 80-85°C for 20-30 min to remove the traces of residual impurities to get excellent results. Suggested for various substrate is given below:

Suggested Recipe :

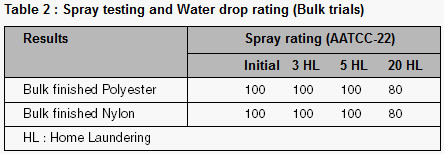

Bulk trials were also taken with 40g/l Careguard-66 (New) on Polyester and Nylon fabric. The fabrics were finished with 40g/l Careguard-66 (New)+5g/l Iso propyl alcohol (IPA)+2g/l Acetic Acid. The bulk finished fabrics were subjected to multiple washings using 1g/l Henkomatic detergent, wash program P99A at 50oC. The bulk finished fabric was evaluated for spray testing by AATCC Test Method 22 and AATCC Test Method 193.

Results and Discussion

The results of spray rating and oil repellency obtained are listed in the Table 1. It can be seen that the initial spray and oil rating obtained after treating the substrates with Careguard-66 (New) are good and also the finish is found to be durable after 20 Home Launderings. The results obtained for the bulk trial as shown in Table 2 shows promising results even after 20 Home Launderings.

Conclusion

Careguard-66 (New) is a new generation water and oil repelling fluorocarbon based on C6 Chemistry. It imparts durable water and oil repelling effects on various substrates viz., polyester, cotton and their blends without affecting the original hand of fabric.

Sarex Chemicals

501, Waterford, ‘C’ Wing, C. D. Barfiwala Marg (Juhu Lane), Andheri (W), Mumbai – 400 058

Ph : +91(22) 6128 5566/4218 4218 E-mail : tcexn@sarex.com

Website