Textile pressure ulcer prevention : Improving quality of life for the bedridden

Immobile patients are in constant danger of developing pressure ulcers on the skin. Empa, Schoeller Medical and the Swiss Paraplegic Centre have worked together to develop a special sheet that is gentle on the skin and helps to make patients more comfortable.

The skin is the most versatile of our organs: It protects the body from environmental effects, contributes to the body’s immune system and supports metabolic functions such as breathing. The skin is always in action. Lack of movement is anathema to it. If a patient does not move, the ever higher moisture levels, pressure and effects of gravity lead to circulatory disorders. This increases the amount of toxic tissue, resulting in ulcers which can lead to life-threatening complications.

This affects two groups of patients in particular: the elderly and paraplegics. There is an up to 50 per cent higher risk of these persons developing bedsores during a hospital stay, despite all the advances in methods of care. Four out of five paraplegics develop a pressure ulcer at least once in their life. Medical technology has recognized the problem. There are many approaches to increasing the comfort of those at risk of developing pressure ulcers. But some of these methods are not sufficiently effective, while others – such as mattresses with changing areas of pressure – are still very expensive.

Bed linen is the solution

Anke Scheel, senior physician at the Swiss Paraplegic Centre (SPC) in Nottwil, Canton Lucerne, did therefore not hesitate when Empa asked the center to become involved in a project to develop a new kind of bed linen. “It seemed such a simple solution,” recalls Scheel, “that’s what I liked about it.” The project is led by Siegfried Derler, who works at the Department of Protection and Physiology at Empa in St. Gallen. The trained physicist has devoted several years to research into the skin and friction, and he is currently working on the development of skin-friendly materials and surfaces. Derler has been researching the medical phenomenon of pressure ulcers since 2006. Back then he launched an initial CTI project for textile pressure ulcer prevention along with the Schoeller Group, a leading international provider of technical textiles. The results were very encouraging, and three years later the partners decided to raise the stakes, inviting the SPC to get involved.

Fewer points of contact thanks to special textile structure

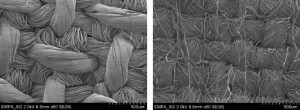

A scanning electron microscope (SEM) image of the novel bed linen (left). For comparison, the image on the right is a conventional bed sheet as used today in hospitals.

“We evaluated marketable synthetic fibers,” explains Derler, “and developed a material with a kind of dot matrix surface.” This special textile structure has two advantages: firstly, it produces fewer points of contact and less surface contact with the skin, and secondly, the microscopic spaces between the dots can absorb moisture. What followed was a highly exciting Ping-Pong process between the Empa test labs and the R & D department of Schoeller in Sevelen, Canton St. Gallen. The industrial partner optimized its weaving techniques, and Siegfried Derler’s team tested the new samples on its sophisticated skin models. By the end of 2009 they were ready: The laboratory results were good enough for the fabric to be tested in hospital beds at the SPC in Nottwil. Twenty paraplegics at the end of their first rehabilitation period offered to act as a test group. Although their skin had already changed as a result of their disability, it had not yet suffered the effects of years of inactivity.

Better circulation and greater comfort

Over a period of eighteen months, experts at Empa and the medical staff in Nottwil regularly checked the patients’ blood circulation as well as the redness, elasticity and moisture levels of the affected parts of the skin. The subjective wellbeing of the subjects was recorded in a questionnaire. And the results were more than satisfactory: The patients sweated less, their blood circulation improved, and they felt significantly more comfortable than in conventional sheets. “We have shown that our method of bedsore prevention using textiles is effective,” says Hans-J-rgen H-bner, CEO of Schoeller Medical. He is currently subjecting the new sheet to tough tests at Schoeller in Sevelen in order to show how it behaves after repeated use and cleaning. Next spring Schoeller Medical hopes to launch its innovation on a commercial basis. “We are currently building up an international distribution system,” says Hans-J-rgen H-bner. He already has one potential customer in the Swiss Paraplegic Centre, which, thanks to the initial positive results, is interested in using the new sheets on a wider basis. “What’s more,” says Anke Scheel, “some of our patients would be interested in using the sheets at home.”

Pressure ulcers are a risk for patients undergoing long surgical procedures. Gel pads, widely used to reduce this risk, are considered to have two major disadvantages: they compromise the patient’s thermo regulation by “sucking” warmth from the body and they do not provide sufficient pressure reduction for prominent body parts.

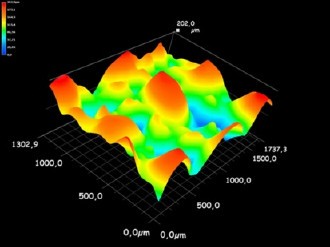

3-D microscope image of the novel bed sheet textile showing the dot-matrix pattern of the surface. This structure ensures only limited contact with the skin and, thanks to the microscopic pores between the dots, allows the material to take up moisture.

Schoeller Group

Schoeller is a textile company with headquarters in Switzerland and international operations. The company specializes in the development and manufacturing of innovative fabrics and smart textile technologies. Schoeller textiles are leading in a number of niche markets worldwide. The “schoeller®-works” sector established in 2009 encompasses function fabrics from Switzerland for uniforms, fashionable corporate wear and protective work wear. The area of “Technologies” is looked after by Schoeller Technologies AG, a subsidiary of Schoeller Textil AG. Together with selected production partners, Schoeller Technologies AG ensures their availability worldwide. License holders are also supported by Schoeller Technologies in the area of marketing and branding. With the establishment of Schoeller Medical AG in March 2011, Schoeller’s textile know-how now extends to the health area. The company’s first product is a modern and good-looking underwear system for the incontinence sector, sold primarily through the company’s own online shop.