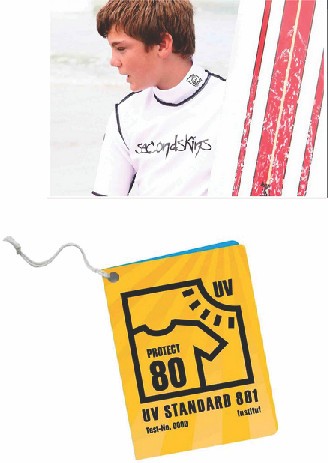

UV radiation is extremely dangerous, primarily for children and young people.Yet protection against the sun is still not taken sufficiently seriously. Special textiles provide the greatest security.

The incidence of skin cancer in Switzerland is among the highest in Europe – and is continuing to climb steadily. The fact that the Swiss do not protect themselves adequately against dangerous UV radiation is also documented by a recent survey of 960 primary and secondary pupils from 13 schools. The troubling results of the survey published in “Swiss Medical Weekly” show that only one-third of the younger pupils are aware of the most important rules for appropriate protection against the sun. Older pupils know more, but protect themselves least of all. 38% of teenage females actually regard sunburn as worth it to acquire a good complexion. Yet dermatologists have long known that the skin does not forget sunburn : 80% of the effects of sunshine that the skin is exposed to before the age of 18 are retained by it and increase the risk of skin cancer. Special textiles are particularly effective :

Special textiles are particularly effective :

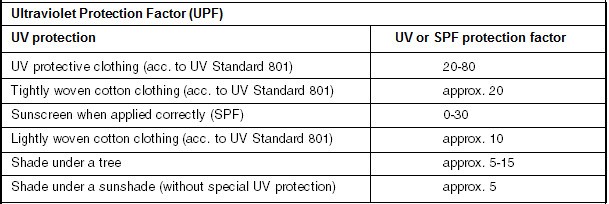

Schoolchildren say they still like to expose themselves to the blazing midday sun, even though UV radiation is at its most intense between 11 a.m. and 3 p.m. That is when they are most likely to protect themselves with sunscreens; but this is only effective if it is used as instructed on the package and is, for example, applied regularly. Wearing protective clothing is still not widespread. Yet textiles can provide better protection against harmful radiation than cosmetic sunscreens – in some cases even better than sun blockers with a high sun protection factor. However, not all textiles are the same when it comes to protection against the sun. Natural fibres such as cotton, for example, provide little protection; the kidney-shaped cross-section of cotton fibres is unfavourable, and the fabric often features small holes through which radiation can penetrate unchecked. Protection is further reduced if cotton textiles have absorbed moisture.

Manmade fibres with Titanium oxide :

Special apparel made from manmade fibres provides better protection. It incorporates titanium oxide particles such as those used in sunscreens. These particles reflect high-energy UV radiation and thus protect the skin. However, it is not only the composition of the material which affects the UV protection factor of textiles – mass per unit area, colour and finishing are also important. For example, dark-coloured textiles offer better protection than pale colours, since dye pigments also absorb UV radiation. A good protection factor can also be achieved by using UV absorbers in the fabric with pale colours.

Protection factors and skin types :

The UV protection provided by textiles is indicated by the “UV Protection Factor” (UPF). This corresponds to the sun protection factor for sunscreens. The UPF indicates the factor by which the product extends the skin’s natural protection. This natural protection depends on the individual skin type. For example, a white T-shirt has a UPF of 10 to 15. This means that someone wearing such a T-shirt is protected against UV radiation 10 to 15 times longer than without this garment.

Defining the UV Protection Factor :

Defining the UV Protection Factor :

In order to arrive at a UPF which is reliable and informative for the consumer, special requirements to which sun-protection textiles are exposed in use must be taken into account. Stretching of the fabric during wear, moisture due to perspiration or salt water and wear adversely affect sun protection and reduce the effective protection time by one-third on average. These effects therefore have to be taken into account in the UPF stated.

UV Standard 801 :

TESTEX is a member of the International Testing Association for Applied UV Protection. It recommends using UV Standard 801 to measure the UV Protection Factor for sun-protective clothing. This is based on the most unfavourable wearing conditions – and is therefore always on the safe side. During testing the textile material is washed and scoured, moistened when measured and stretched in a clearly defined manner. Textiles used to provide shade, such as parasols, awnings or beach chairs are artificially weathered before measurement. UPF definition assumes maximum radiation intensity such as that prevailing in Melbourne at the height of the Australian summer. The most sensitive skin type is also assumed. UV Standard 801 is now the most widely used testing and certification process for clothing textiles such as swimwear, leisurewear and sportswear, as well as for work wear – and also for textiles used to provide shade.

Natural UV radiation

Sunlight is important for human health. The body needs it to form vitamin D, for example, which is important for bone structure. At the same time, the ultraviolet rays contained in sunlight are potentially a source of severe stress and risk for the skin. Due to the change in the way people are spending their leisure time, dermatologists are recording a significant increase in the number of skin cancer cases worldwide. In Switzerland alone, experts anticipate well over 10,000 new cases of skin cancer each year, based on latest estimates. Dermatologists, therefore, warn against excessive exposure of the sun and call for prevention by means of suitable clothing and sun-protective textiles. This is particularly important for children, as their skin is still very thin and only develops full protective mechanisms against harmful UV radiation from around the age of 15. But it is also very important for people who spend a lot of time outdoors in their line of work, such as construction and road workers or gardeners, to use textile sun protection.

Dermatologists, therefore, warn against excessive exposure of the sun and call for prevention by means of suitable clothing and sun-protective textiles. This is particularly important for children, as their skin is still very thin and only develops full protective mechanisms against harmful UV radiation from around the age of 15. But it is also very important for people who spend a lot of time outdoors in their line of work, such as construction and road workers or gardeners, to use textile sun protection.

The UV protection factor (UPF) states how much longer someone using sun-protective textiles or wearing UV-protective clothing can stay out in the sun without suffering damage to their skin. It is comparable to the sun protection factor of sunscreens (SPF). In both cases, the basis for calculation is what is known as the intrinsic protection time of the skin, which can vary considerably depending on the individual skin type. The skin of someone of skin type I with red or blonde hair, blue eyes and a very fair complexion has an intrinsic protection time of approximately five to ten minutes. If they are exposed to the burning sun for longer than this without protection, they risk harmful sunburn. When protected by a textile material with a UPF of 20, this individual can extend the length of time spent in the sun by a factor of 20, in other words, up to a maximum of 1,5 to 3,5 hours (20 x 5 min = 100 min to 20 x 10 min = 200 min), without risking skin damage.

Textiles are intrinsically suited for use as UV protection, as they are able to offer particularly good protection against intense radiation from the sun if suitable materials and fabric structures are used. UV protection factors (UPF) far above those of the strongest sunscreens (sunblocks) can be achieved. However, it is not possible to determine how much UV radiation a textile allows to penetrate to the skin simply from looking at and feeling the textile material. Standardised measuring methods and a specialist test, as conducted by the institutions in the International Test Association for Applied UV Protection, of which TESTEX is a member, are therefore required to determine the Ultraviolet Protection Factor (UPF).

Not every type of skin reacts in the same way when exposed to the sun. Dermatologists therefore make a distinction between five skin types with different intrinsic protection times.

UV-Index

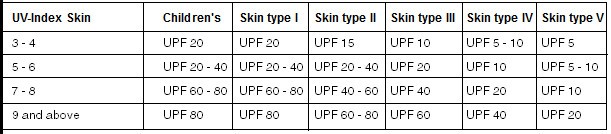

The intensity of the sun, as well as the individual skin type, is crucial when selecting suitable UV protection. The international UV index (UVI) provides information on the intensity of UV radiation in a specific location. The UV index is dependent on the time of day, the longitude and latitude, the time of year, ozone levels and cloud cover. Reflections from sand and snow also affect the UVI level. The daily UVI forecast is published on the Internet by, amongst others, the Swiss Federal Health Office and the Swiss Meteorological Office at www.uv-index.ch for Switzerland, Europe, the USA and Australia.

Children’s skin

In order to provide consumers with a reliable UPF, the particular requirements to which a sun-protective textile is subjected during use must be taken into consideration. In the case of clothing, the stretching of a fabric during wear, moisture from perspiration or sea water and wear during use all affect the UPF. The protection time is reduced on average by about a third as a result of these conditions, and this must also be reflected in the UPF rating indicated to avoid putting the wearer at risk. TESTEX, as a member of the International Test Association for Applied UV Protection, recommends measuring the UPF according to UV Standard 801 for all types of clothing. This is based on the worst case scenario for wearing conditions. The test therefore includes washing the textile material and measuring it while damp and stretched in a specified manner.

In order to provide consumers with a reliable UPF, the particular requirements to which a sun-protective textile is subjected during use must be taken into consideration. In the case of clothing, the stretching of a fabric during wear, moisture from perspiration or sea water and wear during use all affect the UPF. The protection time is reduced on average by about a third as a result of these conditions, and this must also be reflected in the UPF rating indicated to avoid putting the wearer at risk. TESTEX, as a member of the International Test Association for Applied UV Protection, recommends measuring the UPF according to UV Standard 801 for all types of clothing. This is based on the worst case scenario for wearing conditions. The test therefore includes washing the textile material and measuring it while damp and stretched in a specified manner.

Measuring methods for determining the UV Protection Factor UPF

When determining the UPF, a maximum radiation intensity using the solar spectrum in Melbourne, Australia, on 1 January (in other words, at the height of the Australian summer) and the most sensitive skin type are taken as the basis. Under the Australian-New Zealand standard (AS/NZS 4399:1996), however, measurements are only made on new textile materials in an unstretched and dry condition. This test is also based on the solar spectrum in Melbourne, Australia, on 1 January. Since this measuring process does not take account of the special circumstances where clothing is being worn, it is not possible to calculate a reliable sun protection factor for clothing, but only for indoor and outdoor sun-screening textiles on buildings, or for parasols and awnings. The mechanical stress on textiles is simulated with the “Martindale Abrasion Tester”. Here the UV protection factor of textiles is also being measured when elongated In a stretching device.

For further information go to www.uvstandard801.com or contact us by e-mail at: zuerich@testex.com.