The risk of frostbite and hypothermia is a daily reality for those who work outdoors in the wind and rain, in cold rooms at sub-zero temperatures for prolonged periods of time, in and out of vehicles all day or even in draughty factories. As the weather grows increasingly unpredictable, thermal clothing is becoming an all-year staple in the wardrobes of many workers, offering protection in fluctuating temperatures.

Physical activity also causes body temperature to change and so it is unsurprising that manufacturers of thermal work clothing are taking inspiration from the world of sport where staying warm and dry is balanced with the need to stay as light as possible for added comfort and enhanced performance.

This – plus a sense of wellbeing – is achieved by the wearing of lightweight layers that allow perspiration moisture to ‘wick’ away from the body efficiently while also regulating body temperature more effectively than one or two ‘thick’ layers. Stanley Russell, managing director of APT Fabrics, which recently launched the range of Aclimatise® performance apparel, says: “There seems to be a crossover of technologies moving from the skiing/leisure industry into the industrial sector. “Going forward, we can expect to see more garments that are lightweight – free from bulk – so they can offer dexterity and freedom of movement but still maintain the thermal properties required to carry out the job through built-in heating systems.”

Base layers, mid layers, outer layers, neck warmers, balaclavas, lined gloves and beanie hats – thermal clothing comes in many forms but all with the same function: to protect against cold temperatures and the dangers that come with it.

The base layer

The choice of base layer, worn next to the skin as a top and/or leggings, depends on the climate and activity. A simple T-shirt may suffice for mild conditions but more sophisticated thermal underwear could be required where colder environments and less physical activity are likely. Base layers insulate, cool and dissipate moisture so that when you sweat you don’t end up with clothing that in turn may make you cold.

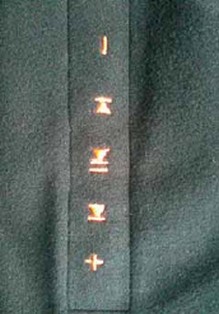

Using the buttons in the sleeve of the fleece, the wearer can control the volume, forwards, backwards and voice control program of either an MP3 player or iPhone (with use of Bluetooth) that has been connected using a dedicated, separate controller

Cotton and polyester are standard base layer materials but merino wool is also becoming popular for its comfort and versatility in a wide range of temperatures, combining moisture wicking, anti-odour and thermal properties. This works well if changeable weather or inconstant physical activity cause the wearer to fluctuate between feeling hot and cold.

Another natural fibre – Viloft, a brand of viscose but which is made from wood pulp – is also being blended with strong and durable polyester to offer better thermal performance than normal viscose and inherent moisture wicking properties as part of a lightweight fabric. Should conditions change, the material construction allows the skin to breathe to reduce perspiration. This fabric blend can also be brushed on the inside to offer extra warmth and softness on the skin. Other base layer trends include flat-stitched seams to prevent chafing and added elastane or Lycra for flexibility and stretch.

The mid and outer layer

Next is the mid layer, whose primary function is to generate extra warmth and breathability beneath the waterproof and windproof jacket or outer layer, which may or may not come with an insulated layer. The choice of mid layer depends on the temperature and humidity that day, but as worn by skiers can include a fleece jacket, merino wool jumper, a thin and lightweight polyester stretch jacket and/or body warmer. The fleece is a traditional mid-layer, but the Aclimatise® fleece from APT Fabrics, which is discussed later in more depth, also acts as an outer layer by offering waterproof and windproof properties as well as extra warmth while remaining lightweight.

This trend for multi-functional thermal garments is also demonstrated by the increasing popularity of interactive mid and outer layers. Often including hivis protection, they comprise a combination of the following: reversible outer jacket with detachable inner jacket and detachable fur lining, collar and sleeves, or reversible body warmer enabling the garment to be worn in up to several different ways depending on the climate.

So whatever combination of layers you opt for, warmth and wellbeing without weight is the way forward for thermal clothing. Aclimatise® : fleece of the future – the World’s first thermoregulating, waterproof, breathable and windproof fleece

Established over 20 years ago, British company APT Fabrics has built up a reputation for developing cutting-edge specialist fabrics for the PPE and performance clothing market and providing expert technical advice.

This has created a strong foundation for its expansion into garment production with its manufacturing partners. Its Aclimatise® branded range of stylish, lightweight clothing uses a unique membrane technology to maintain optimum body temperature for the wearer, whatever the conditions.

The first product from the range has been heralded as the world’s first thermoregulating, fully waterproof, breathable and windproof fleece. Independent testing to industrial standards shows the fleece to be fully waterproof, having achieved a 7psi water pressure threshold.

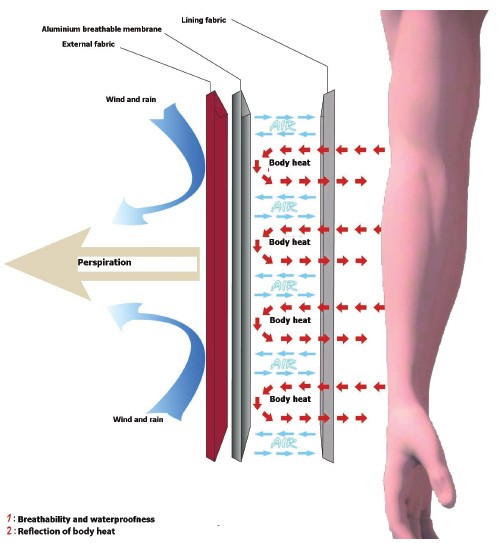

Working in temperatures from -30C to +30C, the fleece offers thermoregulation, keeping the wearer at a constant temperature, providing insulation from the wind and cold and reflecting heat away in warmer conditions through the use of a UV 40+ protective lining.

This is possible through a unique combination of technologies.

An outer fabric (100% micro polyester for the fleece) is laminated to a breathable polyurethane membrane that uses 30% aluminium. A durable water-repellent coating is applied to the surface and the incorporated lining is both antistatic and moisture wicking for enhanced protection and breathability. With no bulky wadding required, the result is a thin, lightweight thermal garment.

The product range is already being expanded through the use of other outer fabrics such as cotton, polyester, nylon or wool. At present, a base layer and waterproof jacket and trousers are available, all of which have been independently tested to industrial standards to ensure the highest level of performance. Suppliers can tap into this enormous potential by working with Aclimatise® to develop a bespoke design for their clients’ specific requirements. The Aclimatise® range is suitable for a range of purposes, having evolved from a lifestyle product into the workwear and outdoor markets, and managing director Stanley Russell says: “The range is extremely versatile and hi-tech. There is nothing else like it in the market but it’s affordable too. It can be used anywhere where you have changing environments and require a lightweight product.

“As a lifestyle product, the fleece, for example, can protect an ageing population from the cold and also help to bring spiralling energy costs down by wearing it instead of turning the heating on. In work environments, the fleece can be worn anywhere from cold storage areas to outdoors, where if it rains you don’t have to carry a jacket with you because you are already protected. The thermoregulation properties also make it ideal for use by Special Forces operating in desert areas where there are extreme changes of temperature.”

The Aclimatise® fleece comes in a number of colours: black, navy, royal blue, grey, olive, bottle green, Ferrari red and breast cancer pink. If desired, it can incorporate integrated Connected Wear technology – a system that allows fabrics to use embedded controllers for operating electronic devices, in this case an iPhone or MP3 player. Crucially, it is still machine-washable.

This futuristic feature has been designed with the lifestyle market in mind but may prove useful to those wearing it at work, where easy access to incoming phone calls can increase safety and efficiency. APT Fabrics is looking for distributors and manufacturers to work with on the Aclimatise® brand as it continues to grow in size and scope. For more information contact :

APT Fabrics Ltd.

18 Tullykevin Road, Greyabbey BT22 2NB (UK)

Tel: +44 (0) 2842758661 Web: www.aptfabrics.co.uk or www.aclimatise.co.uk

The WINDSTOPPER® Spotlight Fabric from Gore and Klopman

Cabela's Trans-Alaska Anorak (200g) Windstopper® Insulated Shell Price : $249.99 Totally Windproof - Extremely Breathable - Water Resistant - Insulated Warmth The Windstopper® fabric blocks wind but still allows sweat vapor to easily escape, while 200-gram Thermolite® Micro® insulation provides added warmth. A removable fur ruff around the three-piece adjustable hood also helps to seal in warmth. W.L. Gore and Associates (UK) Limited (www.gore-workwear.co.uk)

Gore and Klopman are two of the most renowned and respected brands in quality workwear and performance textiles, and when they get together to develop a new fabric, the resulting product is sure to be a winner.

That’s certainly the case with Windstopper® Spotlight with Duraclean by Klopman, a unique, high visibility, two-layer laminated fabric which is functional, durable and provides outstanding comfort and protection. This technically advanced fabric combines the product leadership in functional membrane technology of W.L. Gore Associates Inc with the manufacturing expertise of Klopman International, Europe’s leading producer of polyester/cotton blended fabrics for workwear, protective clothing and casual apparel. Klopman has the exclusive rights to sell the product to existing Gore customers and potential new customers approved by Gore.

The development came about after the Technical Oriented Fabrics division of Gore formed a strategic partnership with Klopman specifically to produce a high visibility, laminated fabric ideal for safety jackets and trousers. The result of that partnership is a superb, lightweight polyester/cotton fabric that provides high levels of performance and functionality, thanks to the Gore Windstopper® membrane, which ensures efficient protection against windchill as well as maximum breathability. The new fabric is also extremely durable, being both abrasion- and tear-resistant and constructed to withstand over 30 high temperature laundry cycles, which means it conforms to EN ISO 9237, the new product classification on durability of windproofness after 30 industrial wash cycles. In addition, the Duraclean fluorocarbon technology, which provides a soil repellent and soil release finish on the fabric surface, helps to maintain the high visibility properties so essential for the wearer’s safety.

As Jim Findlay, product specialist at W.L. Gore and Associates, says: “The superior lamination durability of the Windstopper® fabric process together with the fabric’s inherent strength, colour fastness, resistance to abrasion and tear plus the ability to withstand regular high temperature laundering combine to deliver all-round durability & performance.”

Gore Windstopper® membrane fabrics are extensively used in corporate and PPE garments for skin-to-shell layers – base, mid and outer layers. Whether as a single layer or as part of a garment system, the protection they offer against windchill, their breathability and quick-drying properties make them suitable for garments designed to be worn in a wide range of conditions and environments. The efficiency of Windstopper® fabrics means fewer bulky layers are needed to keep the wearer warm and dry, thus ensuring lightweight comfort whatever the weather.