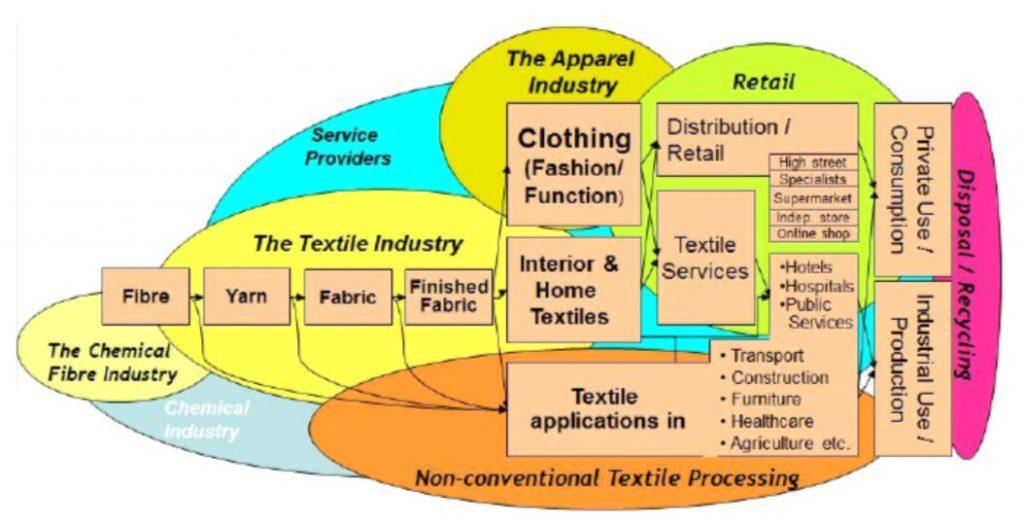

The principal stages and industrial activities along the textile value chain

The principal stages and industrial activities along the textile value chain

Textiles and even clothing or fashion products are becoming technology- and knowledge-intensive products. Today a wrong chemical compound in a clothing product can pose a big business risk for a brand or retailer. And the correct quality of a technical textile material used for such critical application as a filter, an airbag or a medical device is so crucial that customers are rarely willing to replace an established supplier for a competitor that offers a similar product for a lower price.

The European Way Of Process Innovation: Materials Preparation & Processing

The raw materials – natural and man-made or synthetic fibres – used by the European textile industry are to a large extent produced outside Europe. While a certain range of niche natural fibres (e.g. wool or flax) as well as specialty man-made cellulosic and synthetic fibres are produced within the EU, larger production capacities of cotton and basic synthetic fibres exist in Mediterranean partner countries such as Turkey (cotton and synthetic fibres) or Egypt (cotton).

The production of these textile materials has quite a large resource and the case of natural fibres environmental impact, leading to different ecological footprints of different fibres. The starts to play an increasingly important role in textile value chains and end markets which are demanding more sustainable materials. Also the availability of the fibres is not at all times secured, especially in the case of natural fibres, which gives rise to sometimes strong price fluctuations and instability of the markets served by the EU T/C industry. To be able to supply the EU-textile and clothing industry with sufficient raw materials at a fair price and with a minimum of environmental impact, there is a need for more inside or near EU-based sources of textile fibres. This will strengthen the European T/C industry and give them a better competitive position in the world.

A further important trend is the development of new functional and high performance fibres for very specific and often niche end market applications. These are essentially synthetic fibres and their new properties & functions can be based on:

- New/improved polymers & additives

- Multicomponent fibres and multifilaments

- Fibre shape/dimension (mico-/nano-fibres)

- Fibre surface structures

Such speciality fibres are generally produced in small quantities at cost multiples compared to commodity fibres. Blending of conventional fibres with such specialty fibres is therefore a common approach of achieving materials with improved properties at economically acceptable costs.

Finally reclamation and recycling of fibre materials from either production or post-consumption waste starts to play an increasing role, both driven by sustainability approaches as well as regulatory developments which require that a higher percentage of post-use products such as vehicles, but also construction materials (e.g. carpets) and even clothing be reused and recycled at the end of their life.

Sustainability & resource-efficient processing

Sustainable business operations focussed on resource-efficiency can lead to significant cost savings and at the same time offer interesting market opportunities from customers actively looking for products with a lower environmental footprint based on proven facts, rather than simple “greenwash”.

The main resources textile and clothing manufacturing companies utilise are energy, water, materials and chemicals.

Energy

While the energy-intensity strongly depends on the type of manufacturing processes used by the company, the following strategies are recommendable and beneficial for all companies:

- Strategic review and selection of primary energy source mix, incl. the potential of local energy generation (solar, wind, waste…)

- Detailed measurement & monitoring of energy-consumption

- Investment in energy-efficient production technologies and other energy-consuming equipment (heating, lighting, transport…)

- Adoption of better production planning/organisation using energy consumption as one planning parameter

- Awareness raising and training of staff to establish energy-efficient behaviour.

Water & chemicals/auxiliaries

Textile companies especially those active in dyeing, printing and finishing processes use significant amounts of water both as carrier of chemicals and for removal of excess chemicals from treated textiles (washing). Water usage generally engenders 3 types of costs: (1) cost for fresh water drawn from ground water or the municipal water grid, (2) costs for treatment and disposal of waste water and (3) the cost of energy for moving and heating water as well as for water removal after treatment (drying). For companies using a significant amount of water it makes perfect business sense to adopt strategies for lowering the use of water and thereby the costs related to it.

Measures that should be adopted include:

- Investment in technologies with low process water needs, even the adoption of water-less textile processing technologies (digital printing, plasma, CO2, UV, hotmelts etc.) becomes an option for certain materials and applications

- Water recycling and re-use, including recovery of energy (heat) from process water

- Efficient use of chemicals for minimum water pollution and post-process recovery of excess chemicals

- Use of environmental friendly chemicals (e.g. bio-chemistry), which requires less or no waste water treatment

Materials

Materials in the form of fibres, yarns, unfinished or finished fabrics are in important input cost component for every textile or clothing manufacturer. While every company naturally seeks to source the materials that meet their requirements at the lowest possible cost, it is also important to focus on the processing of materials in a way that the least possible material loss or waste occurs. For production waste that inevitably occurs, reutilisation or valorisation strategies should be adopted.

Strategies to explore include:

- On demand material sourcing to avoid unnecessary and depreciating material stocks

- Quality material sourcing to avoid product defects/waste due to poor material quality

- Investment in material-efficient production technologies

- Staff training to avoid waste generation due to faulty machine operation, poor production planning or simple negligence

- Collection, re-processing or selling of production waste

General strategy and behaviour

Traditionally the clothing/fashion and the home/interior markets were the dominating end uses for fibres and textiles produced in Europe and around the world. However fibres and textiles are becoming an increasingly important material for products in the transport, construction, healthcare, protection, sports, agriculture, packaging, industrial and environmental markets.

Beyond focus on specific resource components or production processes at factory level, resource efficiency should also be an integral part of overall business operation and strategy.

Companies that adopt and enforce resource-efficiency strategies across their entire sphere of influence including suppliers, customers, service providers, workers and management will discover many positive effects beyond pure cost saving. They can become “poster children” for a new concept of industry as a responsible actor within their community and a welcome and privileged partners for investors, policy makers, media and the general public.

Advanced processing technologies for technical textiles

Innovative applications in construction, transport, energy and medical markets all call for the incorporation of structures which are flexible, near net shaped and which can be produced continuously. These new applications present challenges for traditional metallic and non-metallic materials and production processes. Fibre and textile based engineered structures can provide new solutions to these industrial challenges, introducing major new opportunities to the sector.

Developing the technologies to drive tailor-made solutions and products for high value applications will be key for the future of Europe’s technical textile manufacturing industry. The production of materials and components with the required flexibility, mechanical properties, drapability and porosity in a highly reliable and productive way is a key requirement for the technical textile industry.

Textile structures and surfaces

There are sheer endless ways of creating complex textile structures out of fibres, yarns or two-dimensional fabrics. In addition to the most common and established processes such as spinning, flat weaving and knitting, sewing or traditional process for niche applications such as embroidery or narrow fabric weaving, novel processes to process advanced materials or generate structures with highly specific shapes and properties have developed and adopted by the industry in recent years.

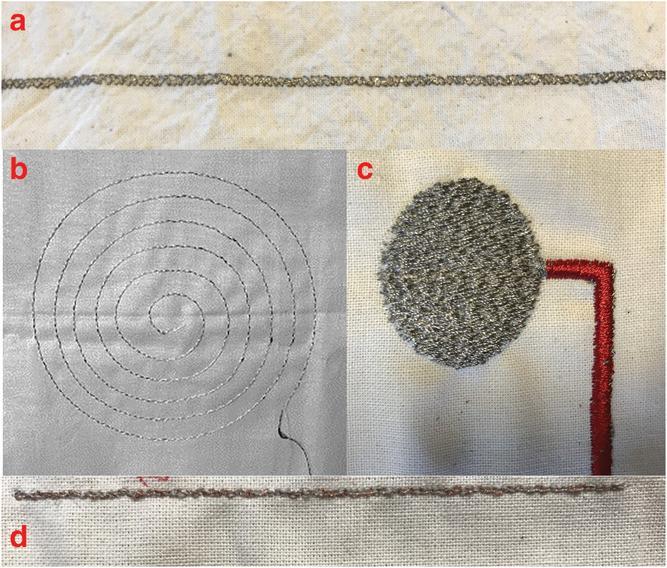

Conductive yarns can be embroidered with or without the conventional yarns to create an electrical conductivity feature on the textiles to let the current pass through embroidered design

a) Embroidered silver yarn on the fabric. b) Embroidered stainless steel yarn as an antenna. c) Embroidered textile electrode for ECG measurements. d) Embroidered copper yarns.

a) Embroidered silver yarn on the fabric. b) Embroidered stainless steel yarn as an antenna. c) Embroidered textile electrode for ECG measurements. d) Embroidered copper yarns.

Such structuring technologies include:

- Filament extrusion including bi- and multicomponent fibres

- Various non-woven manufacturing technologies

- Circular knitting

- Warp knitting

- Braiding

- 3D weaving

- Welding, gluing and taping technologies

- Textile composite manufacturing technologies

A second broad field of processes and related technologies concern the treatment of textile surfaces to give them highly specific functions. The most commonly used processes include dyeing, printing and a wide range of further wet processing technologies to finish fabrics usually through the application of specific chemicals.

Newer technologies for textile functionalization are listed below. These have been compiled by an expert group of the European Textile Technology Platform assessing the industrial state-of-the-art of a number of innovative resource-efficient textile surface treatments.

- Digital inkjet printing

- Supercritical CO2

- Hot melt/adhesive technologies

- 3D printing/polymer deposition

- UV coating

- Atmospheric plasma

- Catalysis

- Magnetron sputtering

- Ultrasonic technology

- Laser technology

- Spraying

- Integrated manufacturing

Complex, hybrid & smart materials

The synthesis of coatings on textiles fibers enables functionalization of their properties. For example, a magnetron with a grounded cathode and positively biased anode can be used as a source of plasma. The textile fibers can be covered by the 2 µm to 3 µm thick coatings of Ti and TiN deposited at both sides of the samples by sputtering of titanium target in Ar or Ar+ N2 atmosphere. The front side is exposed to glow discharge plasma and the backside is completely shaded from the plasma. Significant change in reflectance and transmittance of the coated textiles results from this coating. The using of standard magnetron system (grounded anode and cathode at negative potential) resulted in a coating deposition at the textile side exposed to the plasma action only.

Traditionally textile materials were composed of single fibre materials or the combination of 2 to 3 fibre materials generally in the form of a blended yarn (e.g. polyester-cotton, polyester-wool etc.) or the additional of an additional material in the weaving process (e.g. an elastic yarn).

Today textile materials are becoming increasing complex often serving very specific end use applications and combining multiple functionalities. To achieve this, a large diversity of materials are utilised and combined in many different ways. Such multi-material combinations can be achieved by:

- blending standard textile fibres and yarns with highly specific and functional ones

- combining textile with non-textile materials creating multilayer and hybrid materials

- integrating functional reactive materials (microcapsules, photochromics, shape memory alloys etc.) into yarns and fabrics

- integrating smart components such as sensors, LED’s, photovoltaics, energy harvesting & storage components into fibres, yarns and fabrics

New fibre and textile material processing

New fibre and textile material processing

The development of novel high performance textile materials based on aramid, glass, carbon, ceramic, metal, basalt and other fibres also require the adaptation of processing technologies as these materials cannot be simply spun, woven, knitted, dyed or finished like conventional fibres due to weight, stiffness, surface properties etc.

In a similar way production technologies need to be adapted to processes highly delicate/small-scale materials micro- and nanofibres, electrospun filaments, medical purpose materials, sensor integrated fibres or yarns, piezoelectric fibres and may other exotic high added value fibre based materials.

New structures & surfaces

Most yarns and textiles are produced in relatively standardised material batches such as yarn bobbins or fabric roles produced on production equipment corresponding to such standard size parameters. As various technical textiles are used in either very-large or very-small dimensions highly customised manufacturing equipment is needed which sometimes need to be specially engineered for individual customer orders.

Realisation and efficient handling of hybrid, multiaxial or oddly shaped structures also requires specialised manufacturing and handling technologies as well as innovative finishing/surface treatment technologies.

Efficiency

In order to meet strict cost and quality requirements textile manufacturing operations need to constantly drive efficiencies including:

- low resource consumption

- high-speed/high-precision production

- low defect operations and on-line quality control

- process integration & intensification

Flexibility/Versatility

A company’s exit of commoditised mass textile and clothing markets almost always entails a reduction of average order/manufacturing batch sizes, faster changes of manufacturing batches, need to offer a higher variety of production types/qualities and the capability to respond very quickly to new customer demands.

Manufacturing operations have to integrate such capabilities through:

- Investment in efficient small batch/lot processing/manufacturing technologies

- multimaterial/multiprocess technologies

- flexible factory organisation and planning

- Efficient supply chain communication and logistics