More than 500 participants informed at Aachen-Dresden International Textile Conference in Aachen (November 24-25, 2011) about new materials and technology.

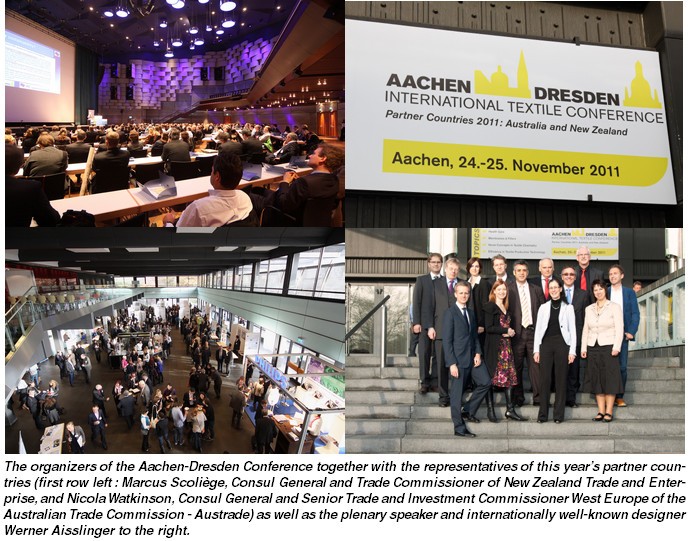

Being in Aachen or Dresden at the end of November is already a fixed point in the calendar of textile experts from materials & finishing and machinery & processes. The 5th Aachen-Dresden International Textile Conference took place in Aachen on November 24 and 25 provided a dense and versatile programme to the 500 participants – 20% of which were international guests from 25 different countries: plenary lectures, 46 technical papers, more than 80 poster contributions, four excursions to textile companies, and a special presentation of this year’s partner countries Australia and New Zealand.

Being in Aachen or Dresden at the end of November is already a fixed point in the calendar of textile experts from materials & finishing and machinery & processes. The 5th Aachen-Dresden International Textile Conference took place in Aachen on November 24 and 25 provided a dense and versatile programme to the 500 participants – 20% of which were international guests from 25 different countries: plenary lectures, 46 technical papers, more than 80 poster contributions, four excursions to textile companies, and a special presentation of this year’s partner countries Australia and New Zealand.

Under the heading “Topics – Markets – Chances”, the plenary session was a starting point for reflecting and discussing markets, changing environments, socio-political developments and visions for the textile and apparel industry. Nicola Watkinson and Marcus Scoliège as the representatives of our partner countries reported on possible research and business co-operations with Australia and New Zealand. Speakers of both countries talked about the recycling of textile waste, textiles in medical technology and new areas of application for wool and the plasma treatment of textiles. Austrade, the Australian Trade Commission, organized a round table business lunch with speakers and more experts in order to foster networking and future co-operations.

Highlight of the plenary session was the lecture of the internationally renowned designer Werner Aisslinger from Berlin. His projects “hemp chair” and “mesh” are examples of how material innovation and new production technologies inspire the design of furniture and many other products. Aisslinger impressively demonstrates that from the communication of the developers and users of new materials may arise innovative products and open up new markets.

Four symposia with altogether 46 lectures (read some abstracts here) were dedicated to the topics Health Care, Membranes and Filters, Novel Concepts in Textile Chemistry, and Efficiency in Textile Production Technology. Within the Health Care symposium different concepts for the antimicrobial finishing of textiles have been presented.

A main focus was on the functionalization of textile materials for biomedical applications. The spectrum of lectures ranges from textile implants to substrates for stem cell cultivation, neurostimulation leads for the growth of nerve cells, and wound coverings.

Functionalization and surface modification was at the center of interest in the symposium on Novel Concepts in Textile Chemistry. A coating with suitable particles helps reducing the emission of fabrics, membranes and foils which are used, e.g., as sun protective elements. Conductive polymers are coated onto self-luminescent textiles or textile heating elements. Special colour effects are generated on textiles by using nanoparticles and pigments. Especially in the textile finishing the nanotechnology plays a major role. While the initial nano-hype was followed by critical comments and a great uncertainty of the consumers, many safety questions were solved during the last few years. According to Martin Möller, director of the DWI at RWTH Aachen University and organizer of this year’s Aachen-Dresden Conference, the potential of nanotechnology is not yet really exploited: “Nano is a mega-topic and I am sure that by intelligent use of nanoparticles on textiles a broad range of new properties can be generated on technical textiles as well as apparels.”

Membranes and Filters are a growing segment in the area of technical textiles. The contributions to this symposium covered the entire chain, from the special design of fibres to be used for filtration to the construction and production of filter and membrane systems, their functionalization and coating, up to various applications. Here the particular challenges for the cleaning of exhaust gas, protective textiles, air-conditioning technology, and water treatment were discussed.

Traditionally textile machinery was a main topic of the Aachen-Dresden Conference, organized especially by the Institut für Textiltechnik (ITA) of RWTH Aachen University, and the Institute of Textile Machinery and High Performance Material Technology (ITM) of TU Dresden. The symposium Efficiency in Textile Production Technology demonstrated that textile machinery and textile manufacturing are a key branch and strong impulse generator for innovations in the textile and apparel industry. Well-known textile machinery companies presented examples ranging from spinning, to weaving, warp knitting, nonwovens, coating, finishing, and dyeing.

For the first time, the programme of the Aachen-Dresden Conference comprised also excursions. Many participants took the opportunity to visit four companies in the Aachen area. Becker Textil GmbH in Aachen is a weaver and finisher of wool and denim goods. Heimbach GmbH & Co. KG in Düren produces technical textiles, i.e., for filtration and paper machine clothings. Oerlikon Schlafhorst in Übach-Palenberg is the world market leader for ring spinning, winding, and rotor spinning machines. DSM Dyneema in the nearby Netherlands informed the visitors on the numerous applications and processing possibilities of ultrahigh molecular weight polyethylene fibres.

The Aachen-Dresden Conference was rounded up by more than 80 poster contributions coming from both the students of the organizing institutes, as well as other research units, and from foreign universities and research institutes. The poster session, an integral part of the conference, became in the meantime a forum where participants from industry were looking for new co-workers.

The 6th Aachen-Dresden Conference will be held in Dresden, on November 29-30, 2012, and the main focus will be on composites.