Walter Wilhelm and Barbara Zeins

Walter Wilhelm from Walter Wilhelm Associates and Barbara Zeins from Gerson & Gerson analyse the advantages and challenges of sourcing from countries in the Western world compared to Asia.

Items to Consider when Sourcing in a New Region

- Why Move? – Remember new relationships inherently have more unknowns and more risk than existing relationships

- What Benefits? – Normally companies are looking for cost savings but speed-to-market and flexibility may be equally important incentives

- Profile Potential Contractors – Do they match your requirements in terms of products and quantities; where do you find the information?

- Consider Communication and Audits – Language/Travel

- Is Social/Environmental Compliance a Factor?

- Cultural Differences may be important.

Historic Factors Influencing US Sourcing

In the past, “Bigness” was synonymous with “Goodness”.

Pro-Asia

- Lowest cost

- Full Package

- Large quantities

Pro-Western Hemisphere

- Geographic proximity

- CMT Production

- Trade Preferences (NAFTA/CAFTA)

Today’s Factors Influencing US Sourcing

Today, “Nimbleness” is synonymous with “Goodness”

Pro-Asia

- Low cost (but higher % increase)

- Full Package (but less of a differentiator)

- Clustering

- Large quantities

Pro-Western Hemisphere

- Speed-to-Market, Replenishment

- Smaller quantity capability

- Full Package and/or CMT Production

- Trade Preferences (NAFTA/CAFTA)

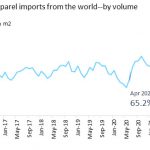

- Recently – costs increasing faster in Asia; capacity concerns because of internal consumption demands

Examining Factors Influencing Sourcing

Labor Rates (US$) – Estimated minimum hourly including taxes & fringes in different countries are :

- United States : $8.70

- Germany : $14.50- $19.00+

- China : $0.52 – $1.10

- India : $0.39

- Bangladesh : $0.19

- El Salvador, Guatemala, Honduras : $0.75

- Nicaragua : $0.41

- Dominican Rep. : $0.62

- Haiti : $0.39

- Mexico : $0.55

Other Factors Influencing Sourcing

Availability of Raw Materials and Components

Asia :

- China has clustered most raw materials and components so available and very efficient

- Other Asian countries are not as efficient but OK.

Western Hemisphere :

- US Suppliers – Many mills have closed; other suppliers have difficulty competing globally.

- CAFTA-DR – Limited fabric (especially woven) available but trims and components normally exist.

- Mexico – Has decent resources but other infrastructure problems.

Shipping Time Comparison

(including estimated costs to Germany, 40 Foot Container)

From/To Surface Cost

Estimate

China (Guangzhou)/Bremen; Sea 30 Days $2,985

China (Guangzhou)/Bremen; Rail 18 Days More Expensive

DR/Hamburg 14 Days $2,800

- Includes estimated time Factory to Port

- Does not include Customs Clearance or in-country shipping to Distribution Center or Retail Store

- Sea shipping can be accelerated (slightly) but at higher cost and larger carbon footprint

Communication, Partnerships, Technology

Communication :

- Product Communication – Veracity of status sometimes questionable

- Travel Differences – consider risk, time, difficulty of travel

- Cultural Differences – In general, Western Hemisphere will be better aligned with Europe

If you are going to source in CAFTA-DR :

- Join the AAPN, the only industry association that dedicates efforts to the region. Membership is not expensive, the meetings are awesome

- Start by finding a service that understands the region and will help you “get started”

Embrace Technology to Facilitate Communications :

- PLM, Supply Chain Management

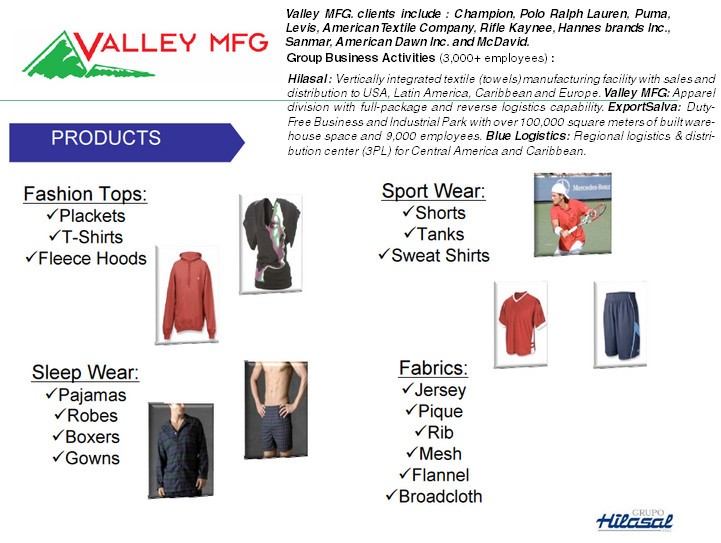

A Few examples of Exceptional Factories

- Denimatrix – Vertical jeans operation; Guatemala

- Valley/Hilasal – Woven & Knit Apparel, Vertical Towel; El Salvador

- Rocedes – Nicaragua

- TexOps – Performance knitwear; El Salvador

- Grupo M/CODEVI – Woven & Knit Apparel, Dom Republic/Haiti

Closing Comments

- Some Europeans have expressed concern that contractors in Central America are unreliable. Is this justified?

- The “good” factories are world class and reliable. The “trick” is in finding which ones are good/reliable and locking in some capacity guarantees.

- Is there a different “mentality” between manufacturers in Central America and Asia? What are the major differences?

- US companies were the drivers in developing Latin America. They forced the companies to operate as “Maquilla” (assembly) operations and later as CMT; until 2005 there was almost no full-package from Central America.

- Central American companies are normally privately owned with little or no government support. Asian companies (especially China) often receive support from support and incentives from government.

- US companies also had a major influence in Asia but it wasn’t practical to have Asia as an assembly only operation; full package almost from the start

- Skills are comparable; work ethic in Asia is A+

Closing Comments

Follow similar guidelines to doing business as in any region of the world.

- Work with a partner that knows the region (AAPN is a good place to start)

- Use the M&S approach of “partnering” with your vendor; develop long-term relationships

- Don’t be an absentee manager; visit your partners

- Communicate, Communicate, Communicate (help develop the protocols, if necessary)

About the Authors

Barbara Zeins :

- President of major girls dress company for many Years

- Has personally sourced products in Asia, Central America and South America

- Participated in study of Dominican Republic apparel industry

- Frequent speaker at industry events involving regional sourcing

Walter Wilhelm :

- Chairman/CEO of Walter Wilhelm Associates LLC

- Has opened and been responsible for offices in Hong Kong, Taipei, Jakarta, Europe (UK, Germany, Italy, Sweden)

- Has worked extensive in the CAFTA-DR region plus Haiti and Mexico for 10 year including major studies in El Salvador, the DR, Haiti and Mexico (for UNIDO) (for UNIDO)

Contact details :

Walter Wilhelm

Walter Wilhelm Associates LLC

2744 E. Eagle Way

Salt Lake City, UT 84108 USA

801.582-1967

[email protected]

Barbara Zeins

Gerson and Gerson Inc.

100 W. 33rd Street, Suite 911

New York, NY 10001 USA

212.244-6775, ext. 222

[email protected]

Profile of Valley Manufacturing

Social Responsibility : Group’s Labor and Social Welfare Policies are fully compliant with national labor laws and regulations. More importantly, they are based on mutual respect and dignity for the individual.

Wages – The vast majority of our employees are paid well in excess of the legally mandated minimum wage.

Working Hours & Working Conditions – 44 hour workweek, allowing for voluntary overtime work with compensation according to law. There are strict industrial and employee safety programs in place in order to guarantee a safe, clean and labor-harmonious working environment.

Benefits – Workers are entitled to : Subsidized health care; Pediatric clinic for the children of employees; Annual health and vaccination fairs; Paid maternity leave; Two-week paid vacation; Retirement plan; Christmas bonus; Personal loans at preferential interest rates; Student loans and scholarships; World class educational facility with a 3-year curriculum in english and computer literacy for employees and their families; Employee transportation.

Child Labor – No one under the age of 18 is employed. Extensive safeguards are in place to ensure total compliance with this policy.

Equal Opportunity – No discrimination based on gender, race, religion or ethnic origin.

Right of Association – Employees have the right of free, peaceful and lawful association.nviaroment

Enviromental Policies : Hilasal plays a leadership role in promoting environmentally conscious practices and programs.

- State of the art water treatment and conservation facilities and environmentally friendly boiler

- Provide water treatment expertise and laboratory services to other companies in El Salvador

- Work with environmentally conscious suppliers

- Use biodegradable dyes

- Promote annual national reforestation programs

Contact details :

Export Salva Free Zone

Km. 24 Carretera a Santa Ana – Colon, La Libertad, El Salvador, C.A.

Tel. +503 2319-2230 Fax +503 2319-2285 Email : [email protected]

(Contact person : Katya Delgado-Vásquez)

Profile of Textiles Opico SA de CV

A vertically integrated private label apparel OEM (original equipment manufacturer) providing complete services :

- Raw material development.

- Apparel product development.

- Logistics and distribution.

- LEAN enterprise and manufacturing process.

- Leadership in environmental and social programs.

TexOps’ customers are amongst the finest active and performance wear brands and retailers. TexOps is a “Multi-Style” factory producing a wide variety of active and performance knitwear. Production cells are cross trained ir at least 2-3 different sew types per operator. Cells flexible to produce both tops and bottoms. Factory averages 19 style changes per week.

3D Prototyping : Fit approvals can be accomplished in days instead of weeks. Reduces product development cycle by 60 days. Savings on courier charges back and forth, reduced carbon footprint.

Contact details :

Textiles Opico SA de CV

KM 31.4 Carretera a Santa Ana

San Juan Opico, La Libertad, El Salvador

T: +503.2319.0800 Email : info@TexOps co

CODEVI was founded in 2003. Currently it supplies 6.8 million pants, 2.9 million Dozen shirts and 2.4 million ladies intimates each year to U.S. leading brands – from concept to retail. CODEVI is a division of Grupo M, a Vertical Textile Corporation in the Dominican Republic founded in 1986