On the right an industrial washing machine, on the left a clothes rail, on which various items of clothing hang on hangers.

On the right an industrial washing machine, on the left a clothes rail, on which various items of clothing hang on hangers.

German Safety rules

If the original condition of a machine is significantly changed, it may then be considered “new”. Then it needs a new declaration of conformity. It must not be operated beforehand.

Maintenance and repair work as well as modernization measures are carried out regularly when operating machines.

If deviations from the original condition of the work equipment result from this work, this can have safety-relevant effects on the operation. The cause can be, for example, changes in the operating and working materials or the modification of the safety technology.

If such modifications are available, the operator must check whether it is a “major change”. If so, the machine is considered to be a new machine. The operator becomes the manufacturer of the machine. At the same time it loses its previous conformity and the CE mark its validity.

In addition, the Act on Making Products Available on the Market and the Ninth Ordinance on the Product Safety Act must be applied. Since this is a “new” machine, its requirements must be met before the machine is started up.

What is a major change?

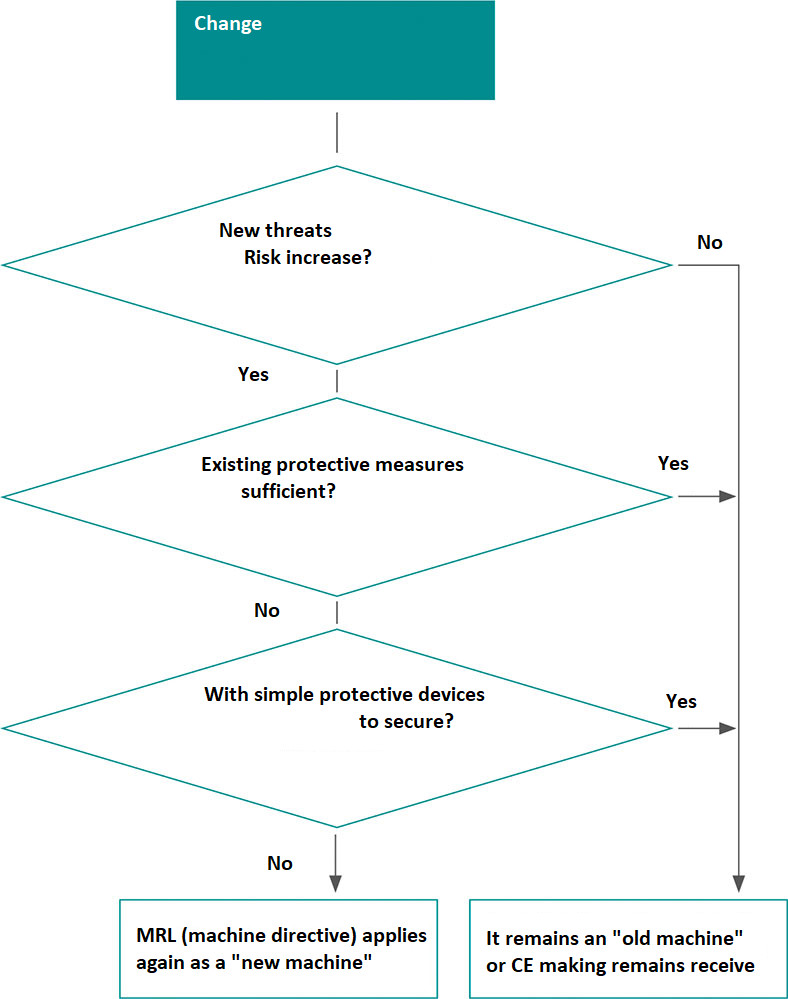

When assessing whether there has been a “major change”, the interpretation paper on the subject of “major changes to machines” by the Federal Ministry of Labor dated 9.4.2015 helps. It contains a decision-making scheme that helps with the assessment.

The diagram shows a flow chart with the decision-making scheme for evaluating protective measures when commissioning machines.

Notes for cleaning companies

Do you operate a dry cleaning machine with hydrocarbon solvents (KWL) or other flammable solvents? As a rule, your system has a CE mark and a declaration of conformity from the manufacturer. With the EU declaration of conformity, the manufacturer/distributor confirms that he fulfills the basic safety and health protection requirements of the machinery directive and by affixing the CE mark he confirms compliance with the EU directives applicable to marketing in the European Economic Area, including on the machine itself .

In this case, the manufacturers have implemented a machine concept for the use of the flammable solvents specified in the operating instructions as intended, which prevents the risk of explosion.

Interventions in this concept influence the safety of the machines and can lead to far-reaching legal consequences. If these interventions involve so-called significant changes, the person responsible becomes the person who puts the machine on the market and thus assumes the manufacturer’s obligations.

Significant changes can be, for example, the use of a measuring device other than that provided by the manufacturer. Other significant changes to the measurement concept can be exemplary:

- the changes in the measuring location at which the concentration is determined,

- a change in the cabling of the meter,

- installation of a new opening in the closed system, which is only secured by a quick-release fastener.

Such changes can impair the reliability of the explosion protection provided by the manufacturer.

If these or similar significant changes have been made to your machine, the conformity must be reassessed and declared. Otherwise the machine may no longer be operated.

What to do if you are not sure whether the planned renovation represents a significant change?

In case of doubt, please contact the BG ETEM sales representative responsible for you for advice. The manufacturer of the machine can also provide information about which changes are still covered by his safety concept and which are not.

(Source: BG ETM)